Method of double solvents, benzene substitutive rectification for separating c9 aromatics

A carbon 9 aromatics, extractive distillation column technology, applied in extraction purification/separation, organic chemistry and other directions, can solve the problems of large reflux ratio, excessive number of trays, large energy consumption, etc., to reduce equipment production load, strengthen Separation effect, effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

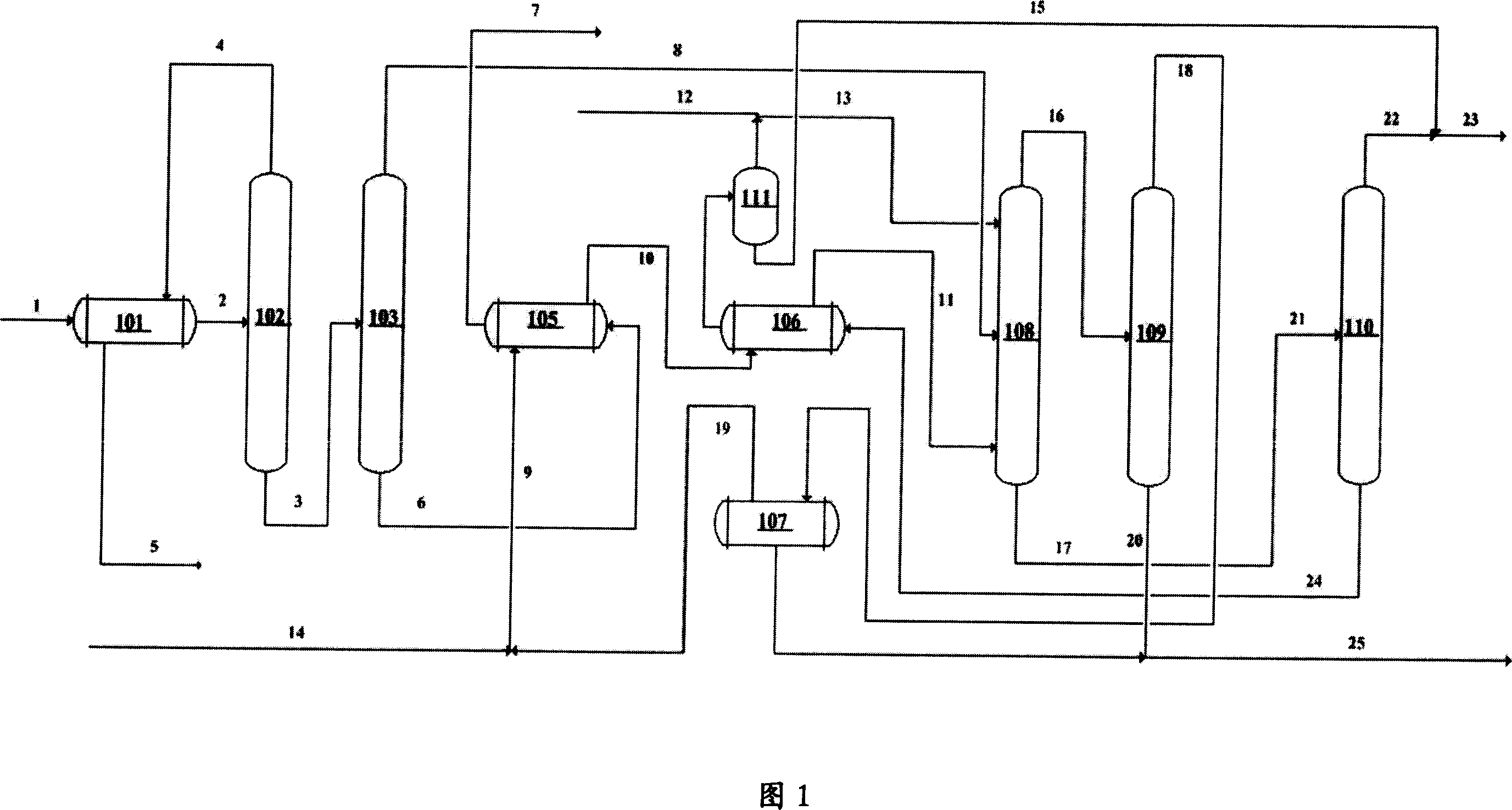

[0038] According to the flow chart in Figure 1, use platinum reforming tower bottom oil as raw material, and obtain mesitylene-o-methylethylbenzene enrichment liquid through precision rectification, use triethyl glycerol as the high boiling point solvent, and diethyl carbonate as the low boiling point Solvent, cooperative extraction and rectification to obtain high-purity trimethylbenzene, o-methylethylbenzene and mesitylene products. The main operating conditions are shown in Table 1, and the composition of raw materials and main products is shown in Table 2. The dosage ratio of high boiling point solvent and low boiling point solvent is shown in Table 3.

[0039] Device No

[0040] Pipeline number

[0041] Material name

example 2

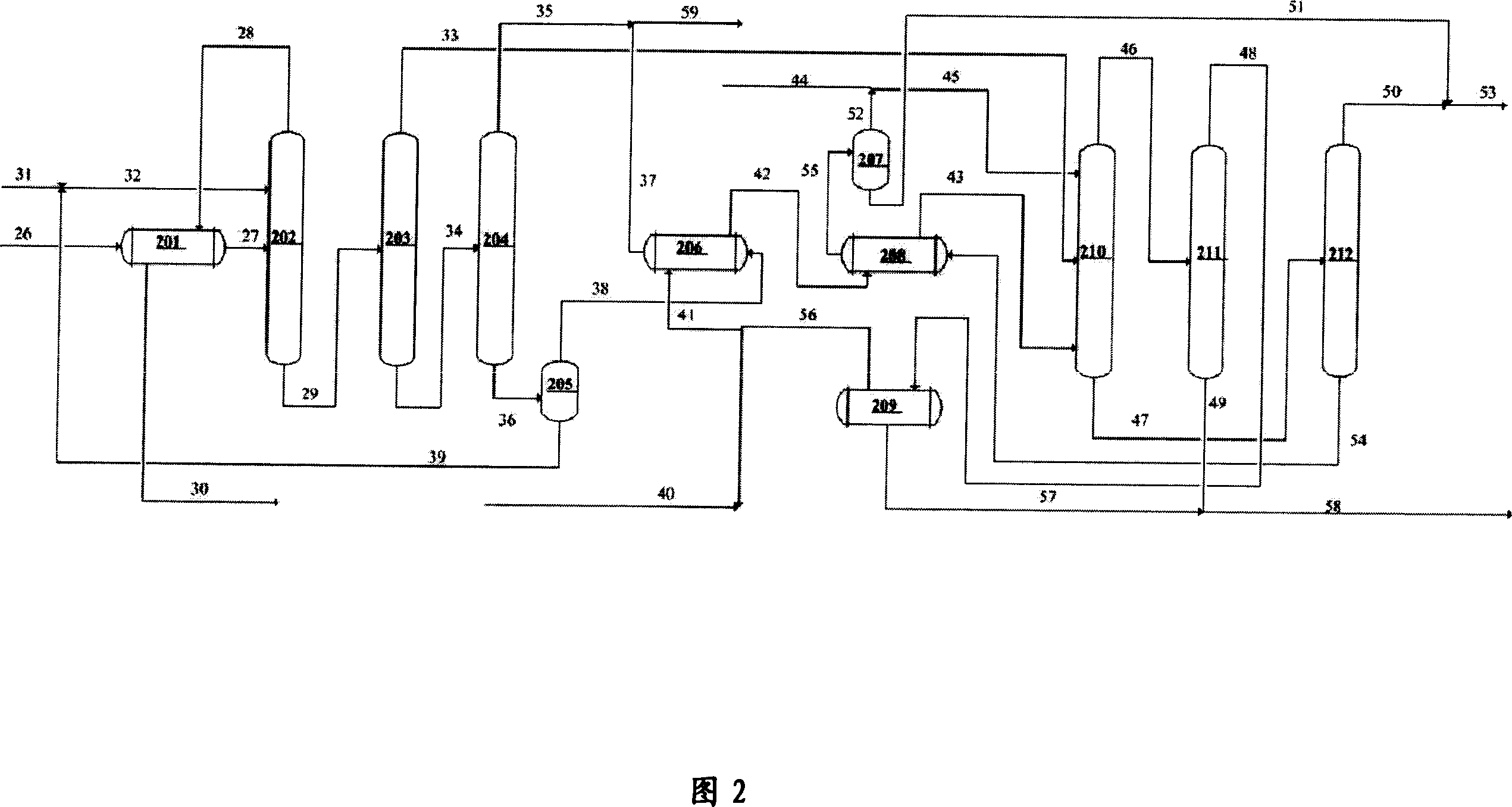

[0043] According to the flow process of Figure 2, hydroxyethyl acrylate is selected as the extraction agent, and the extraction and rectification obtains the mesitylene-o-methylethylbenzene enrichment solution. Other conditions are exactly the same as in Example 1. The main operating conditions are shown in Table 4, and the main product composition See Table 5, and see Table 6 for the dosage ratio of extractant, high boiling point solvent, and low boiling point solvent.

[0044] Device No

[0045] 210, 211, 212 operating conditions are the same as 108, 109, 110.

[0046] Pipeline number

[0047] Material name

example 3

[0049] According to the flow process of Fig. 1, with the material of example 1 as raw material, precision rectification obtains mesitylene-o-methylethylbenzene enrichment liquid, with dimethyl phthalate as high boiling point solvent, diethyl carbonate as low Boiling point solvent, cooperative extraction and rectification to obtain high-purity mesitylene, o-methylethylbenzene and mesitylene products. When the high boiling point solvent changes, the result of its extractive distillation also changes; Now replace the triethylglyceride in the example 1 with dimethyl phthalate, in order to reach the same separation result, the required number of plates and The temperature of the tower still has a certain increase; its main operating conditions are shown in Table 7, and the composition of raw materials and main products is shown in Table 8. See Table 9 for the dosage ratio of high boiling point solvent and low boiling point solvent.

[0050] Device No

[0051] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com