Method of regulating bearing pretightening force using heat characteristics of metal material and its device

A technology for adjusting bearings and metal materials, applied to the rigid brackets, bearing components, shafts and bearings of bearing components, etc., can solve the problems of few applications and difficult to determine design parameters, and achieve the effect of simple and practical installation and great practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] specific implementation plan

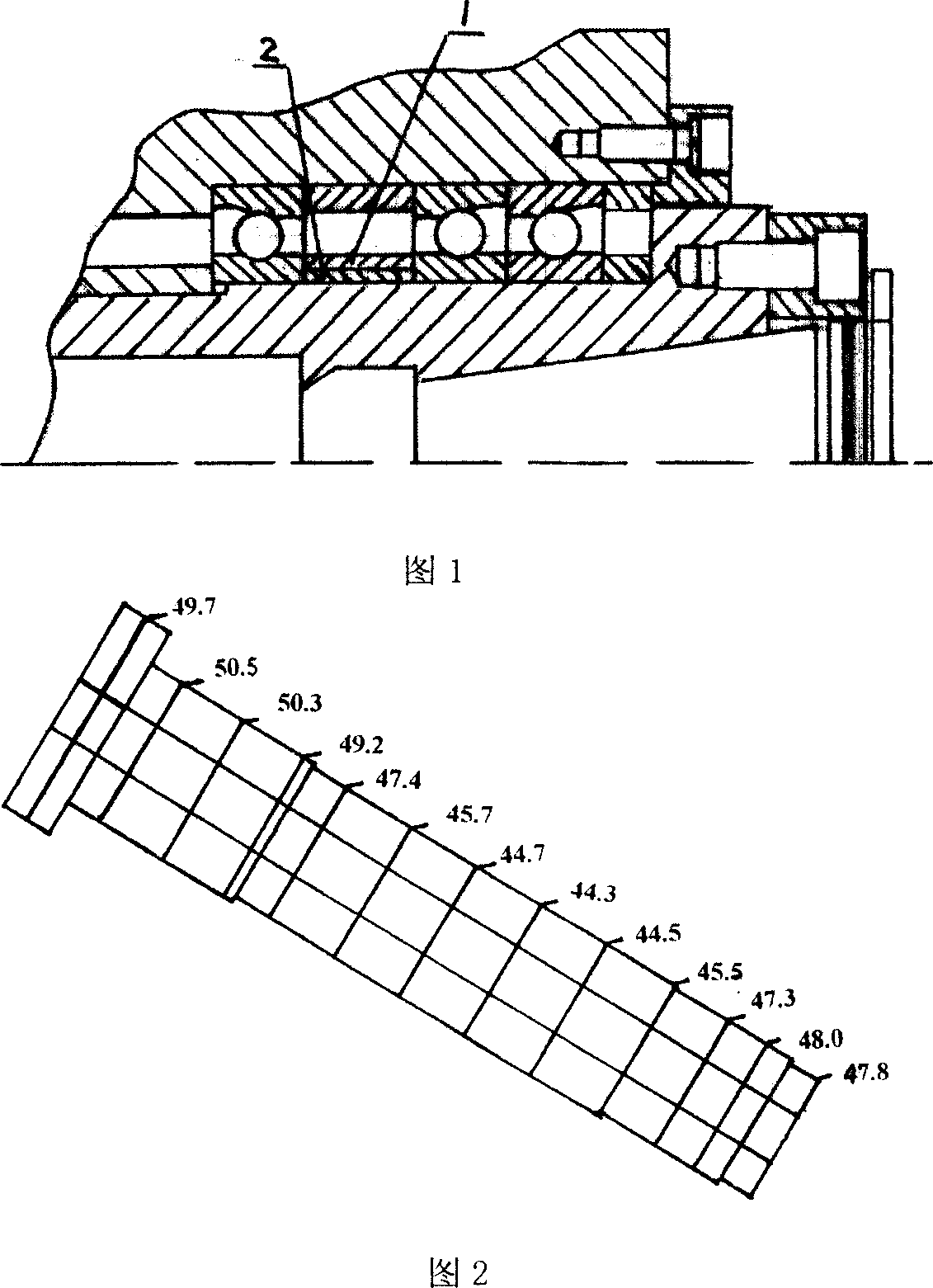

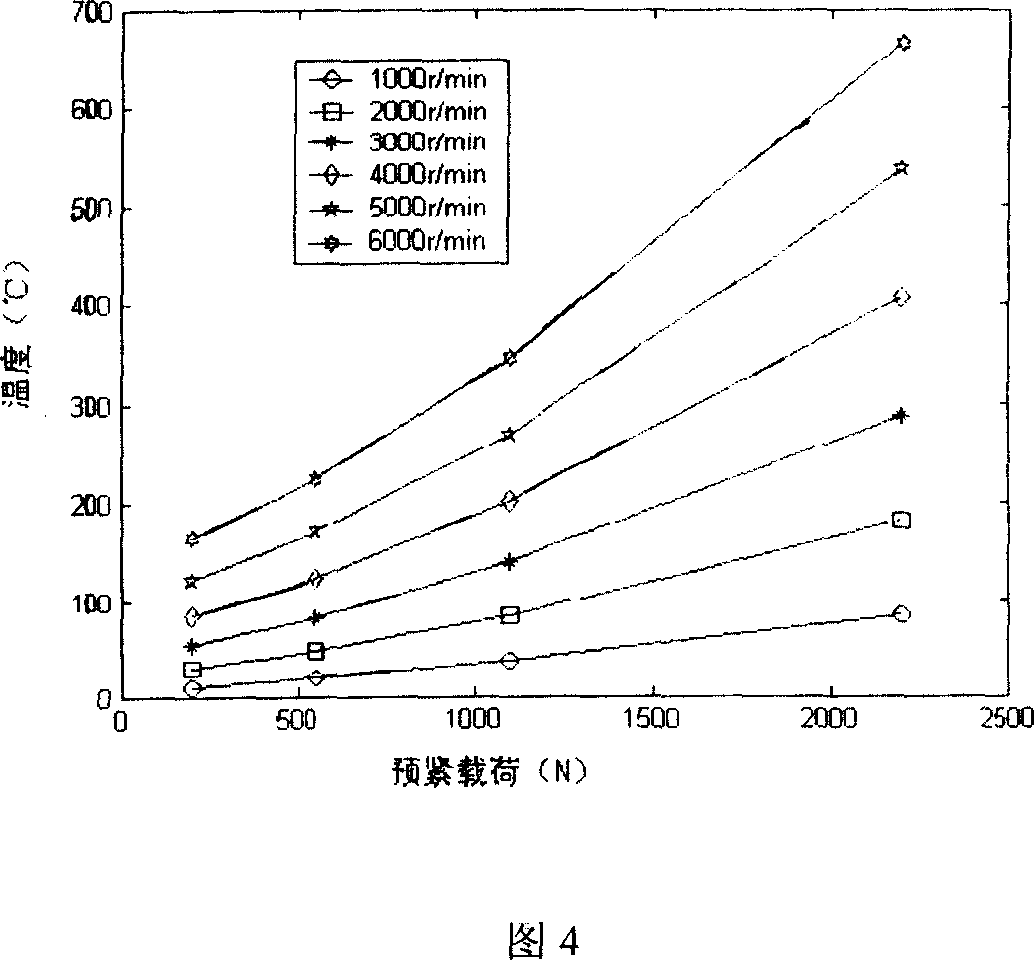

[0048]As shown in Figure 1 to Figure 9, the main reason for the heating of the bearing is that the centrifugal force and the gyro torque acting on the bearing balls due to the increase of the rotating speed increase the friction, and at the same time, the temperature increases to cause the thermal expansion of the bearing, which increases the preload. The friction torque increases.

[0049] The first step in the automatic adjustment of the bearing preload is to determine the calculation method of the spindle heating and temperature rise.

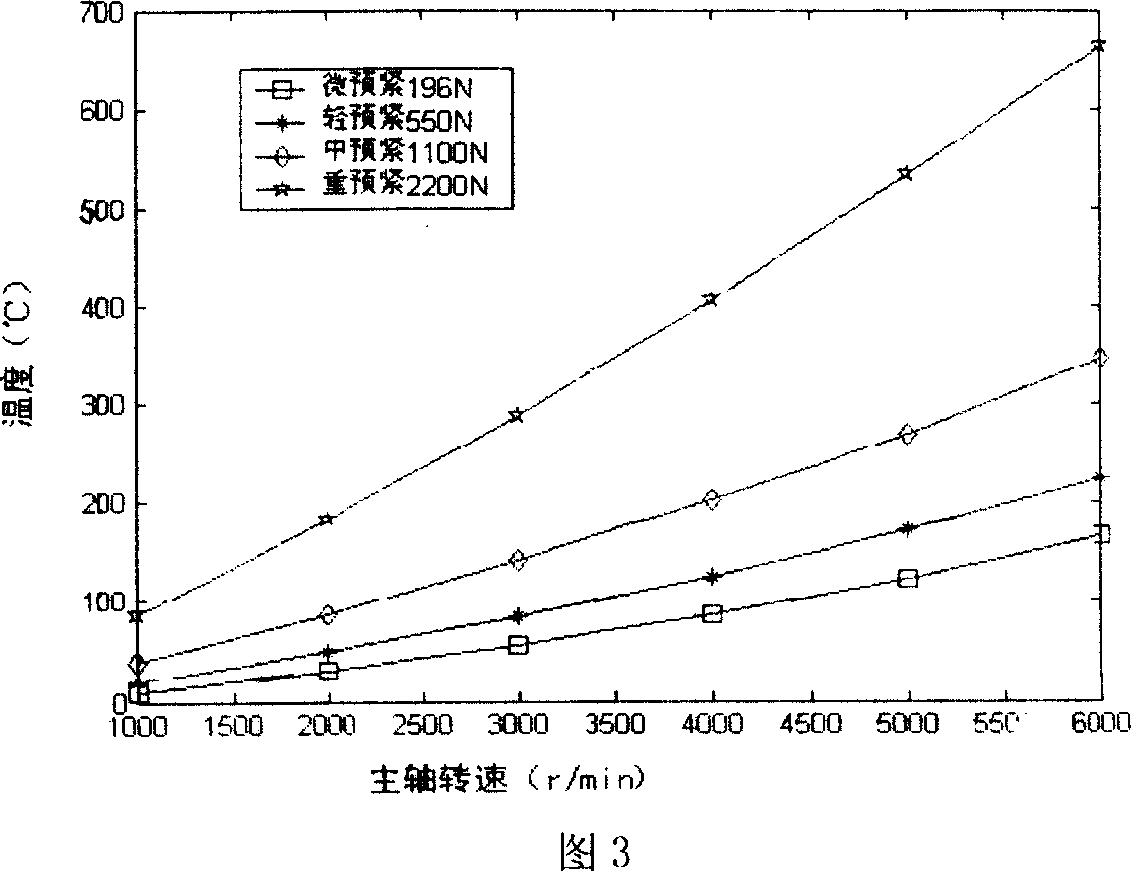

[0050] (1) Establish a thermal analysis model to determine the heat generation and temperature rise of the main shaft. For the temperature distribution of the axisymmetric structure, the cylindrical coordinate system is used to determine the boundary conditions:

[0051] Establish a thermal analysis model: The main factors that cause the temperature rise of the spindle are the frictional moment of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com