Thermal analysis test method and apparatus of magnesium and magnesium alloy deteriorative processing tissue thinning effect

A technology of deterioration treatment and detection method, applied in the direction of measuring device, material thermal analysis, analysis material, etc., can solve the problems of equipment error and human factors concealment, small improvement, small latent heat of solidification, etc., to achieve short detection period, High reliability and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Alloy grade AZ91, the basic operation steps are as follows:

[0057] I), smelting process:

[0058] Use 10kg resistance crucible boiler to smelt AZ91 magnesium alloy, 720℃ magnesite modification treatment;

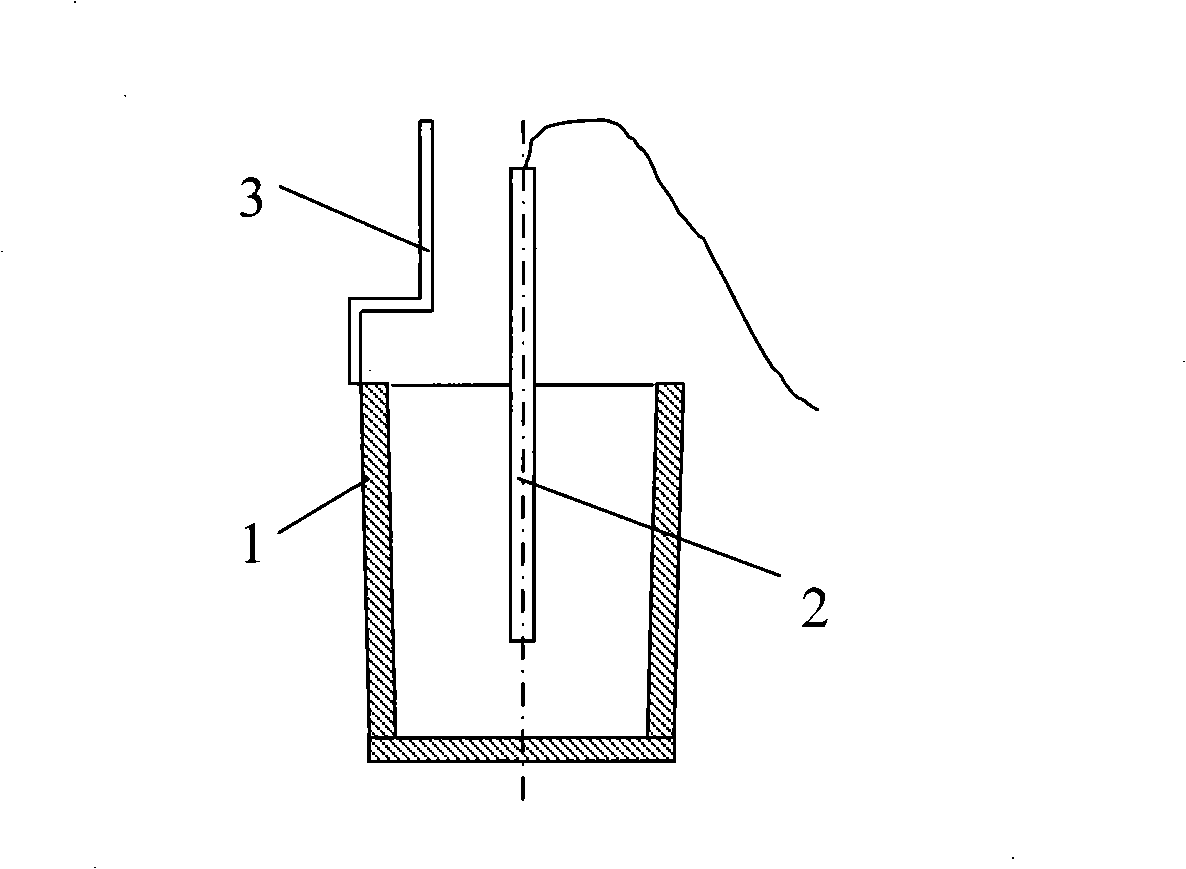

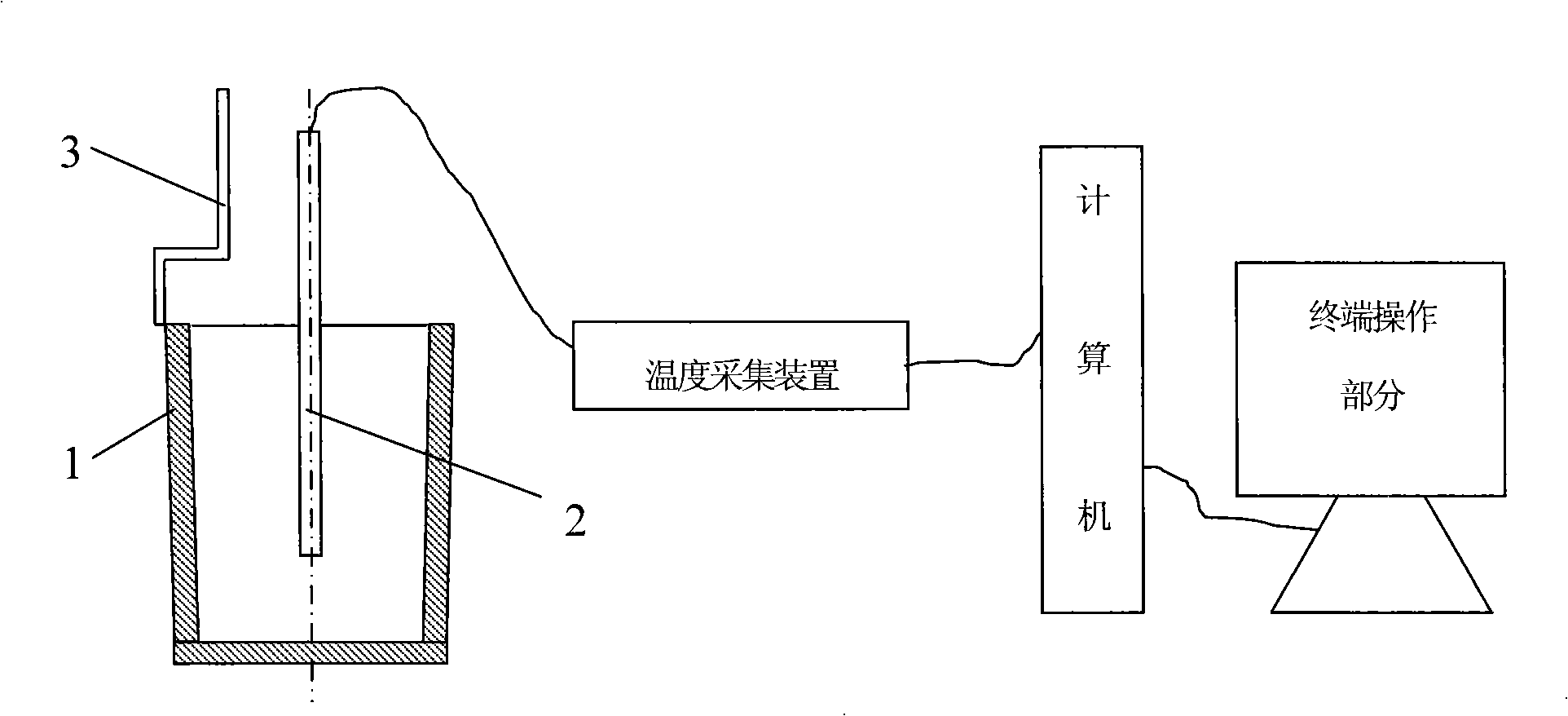

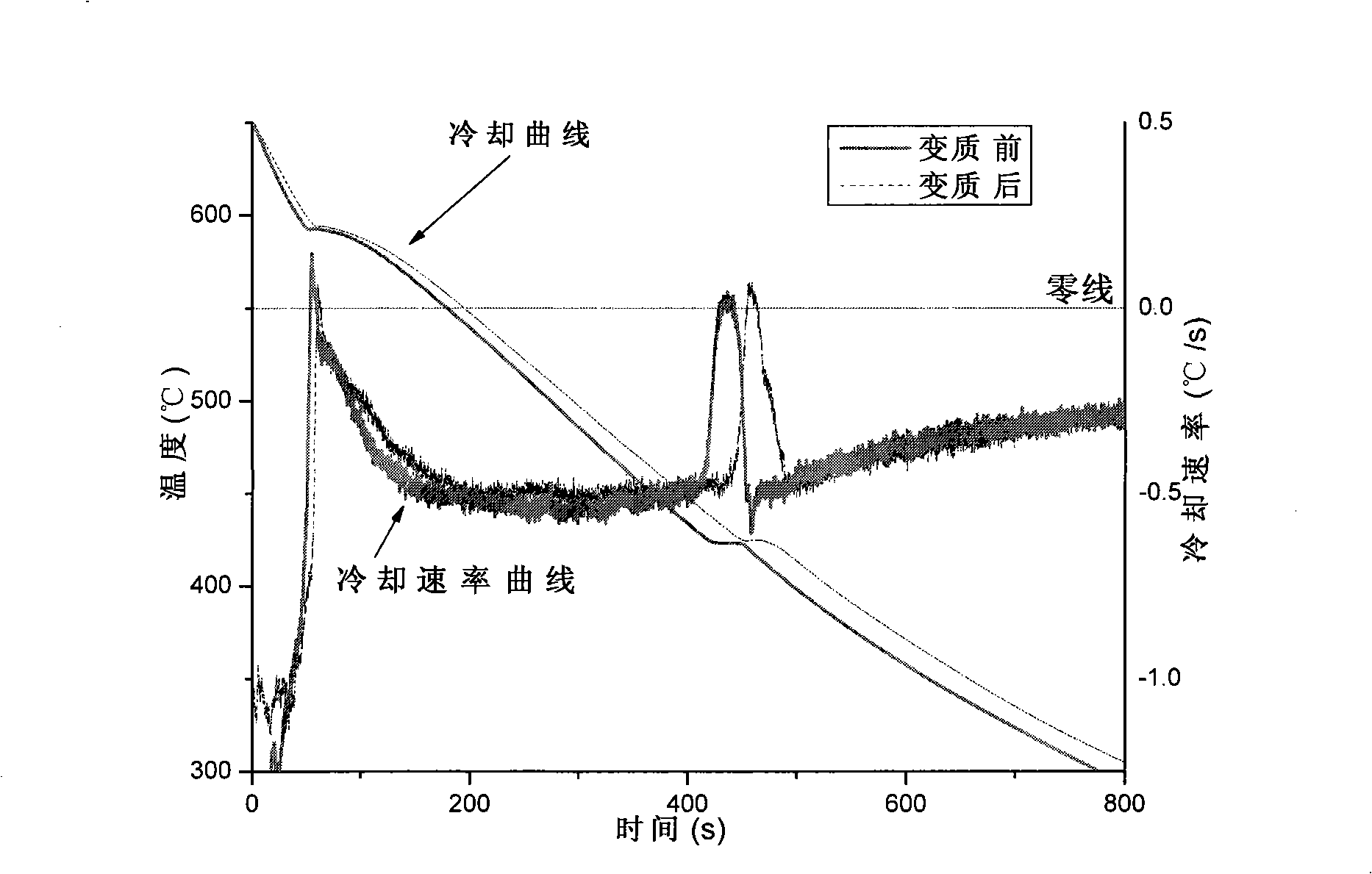

[0059] II), thermal analysis process:

[0060] Before the alloy was poured, samples were taken directly from the melt with a sampling cup at 720 °C, and then the sampling cup was naturally cooled in air at a cooling rate of 0.5-1 °C / s. The material of the sampling cup is stainless steel, the space inside the sampling cup is Φ60mm in diameter at the top, Φ50mm in diameter at the bottom, 80mm in height, and the wall thickness of the sampling cup is 2mm. The sampling cup is preheated before sampling. The preheating method is to soak in the molten flux. The flux used is a special flux for magnesium alloy melting (such as: RJ-2, etc.), and the temperature of the flux is controlled at 700 ° C. The thermocouple is fixed at the center of the sampling cup, 40mm away from ...

Embodiment 2

[0065] The difference from Example 1 is:

[0066] Alloy grade AZ31, the basic operation steps are as follows:

[0067] I), smelting process:

[0068] Use 10kg resistance crucible boiler to smelt AZ31 magnesium alloy, 720℃ magnesite modification treatment;

[0069] II), thermal analysis process:

[0070] Before the alloy was poured, samples were taken directly from the melt with a sampling cup, and then the sampling cup was naturally cooled in the air at a cooling rate of 0.5-1 °C / s. The material of the sampling cup is stainless steel, the space inside the sampling cup is Φ60mm in diameter at the top, Φ50mm in diameter at the bottom, 80mm in height, and the wall thickness of the sampling cup is 2mm. The sampling cup is preheated before sampling. The preheating method is to soak in the molten flux. The flux used is a special flux for magnesium alloy melting (such as: RJ-2, etc.), and the temperature of the flux is controlled at 700 ° C. The thermocouple is fixed at the center ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com