Chip temperature predicating method based on ANSYS finite element heat analysis

A prediction method and thermal analysis technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of high cost, insufficient simplicity and convenience, and achieve the effect of convenient operation, simple operation and accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment illustrates the related theory of chip modeling using ANSYS finite element thermal analysis tool in the present invention.

[0062] (1) Finite element method

[0063] The basic principle of finite element analysis is to discretize the original continuous model body, that is, to decompose the continuous entity into a finite number of small unit blocks that are connected and regular in shape, and describe a certain physical characteristic through the hypothesis of each small unit block. Approximate functions are used to solve the functions of the entire model, thereby converting the original complex infinite degree of freedom problem into a limited degree of freedom problem, which simplifies the solution and is suitable for solving problems such as various complex models, complex boundary conditions, and complex material properties. The solution obtained by the finite element is not an exact value, but an approximate value, and its accuracy depends on the ...

Embodiment 2

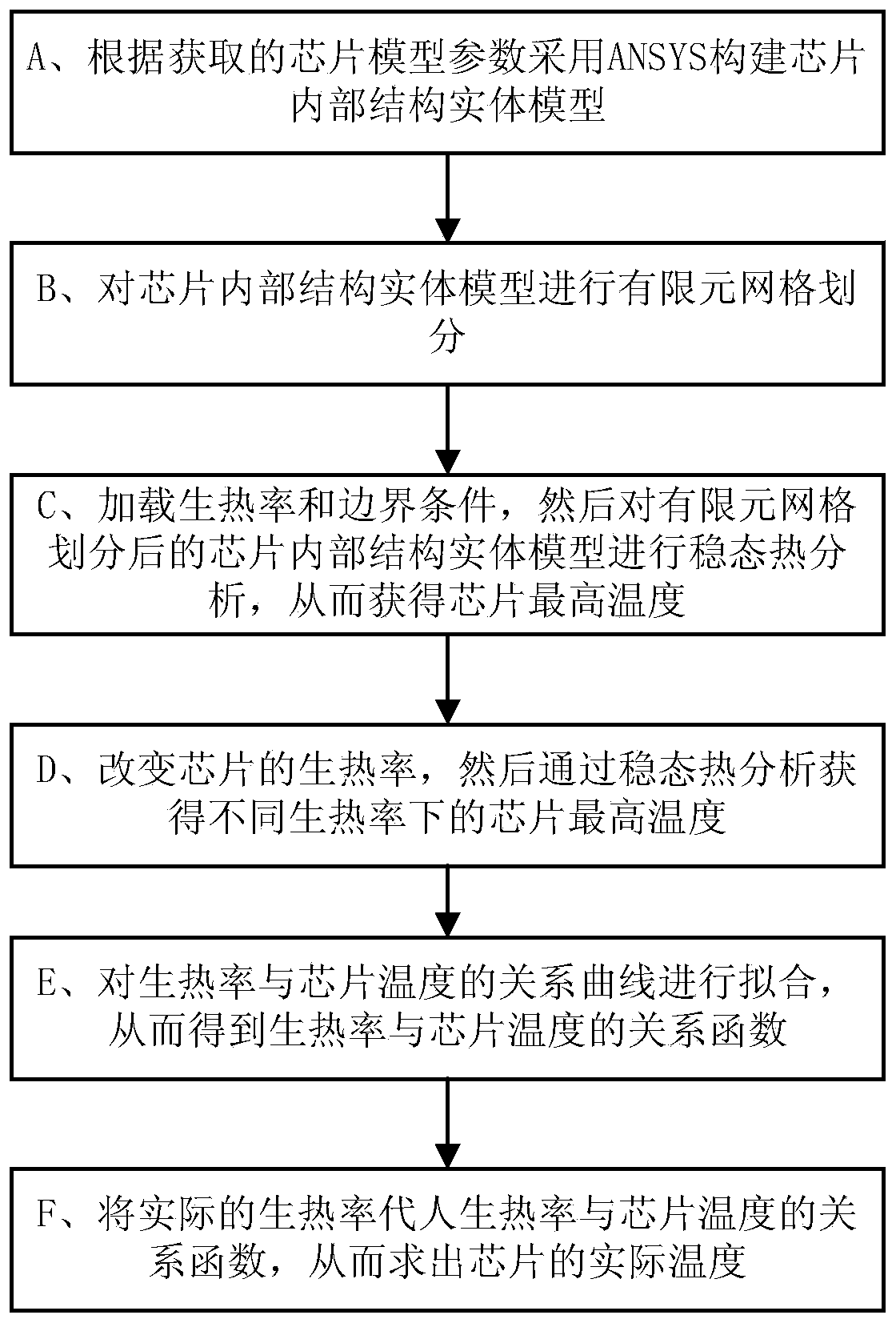

[0084] This embodiment introduces the specific implementation process of the present invention.

[0085] A kind of specific implementation process of the chip temperature prediction method based on ANSYS finite element thermal analysis of the present invention is:

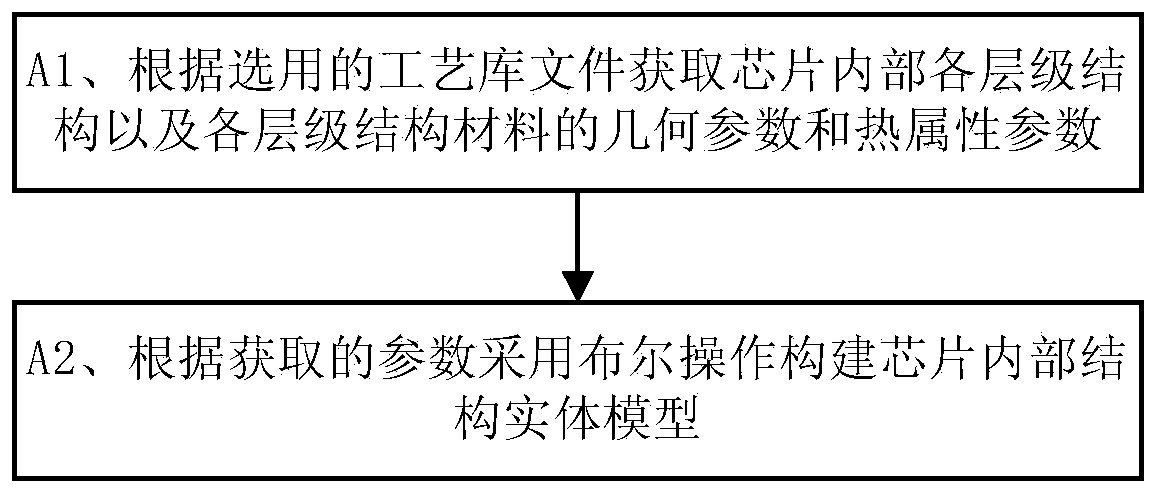

[0086] (1) Search for technical documents and determine the parameters required for chip modeling.

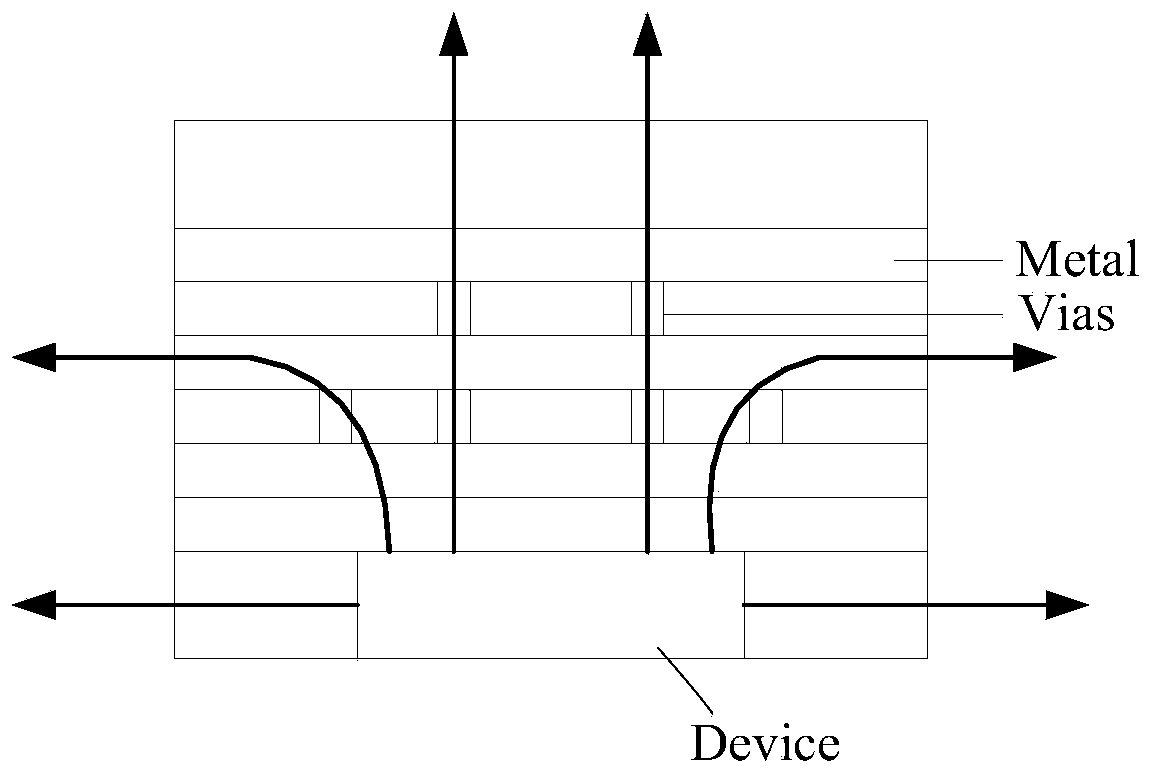

[0087] As shown in Table 1 below, the internal structure of the chip under this process is determined by searching the corresponding process library design documents, including the material thermal conductivity, specific heat capacity, density and geometry of each layer such as the device layer, metal layer, via layer, and passivation layer. thickness.

[0088] Table 1

[0089]

[0090] (2) Use ANSYS to create a geometric model of the internal structure of the chip.

[0091] According to the parameter values in Table 1, the ANSYS thermal model is used to establish the geometric model of the internal structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com