Foamed floor with wood textures

A technology of texture and wood, applied in the direction of AC network with the same frequency from different sources, home appliances, other home appliances, etc., can solve the problem of low added value, difficult to use in a large area, and the shape and appearance of PVC foam floors do not match Use traditional requirements and other issues to achieve realistic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] This specific embodiment is only an explanation of the present invention, not a limitation of the present invention. Any changes made by those skilled in the art after reading the description of the present invention will be subject to the patent law as long as they are within the scope of the claims. Protect.

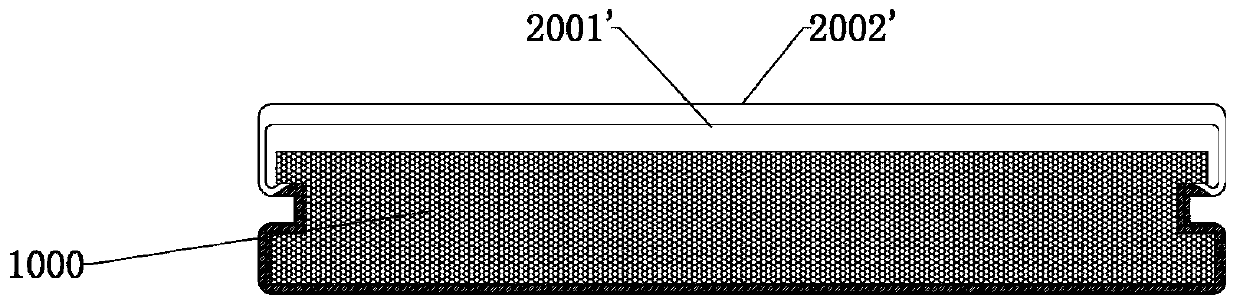

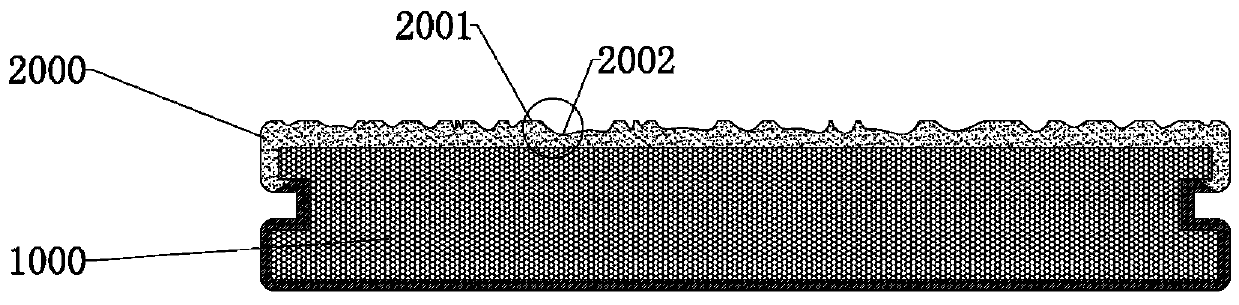

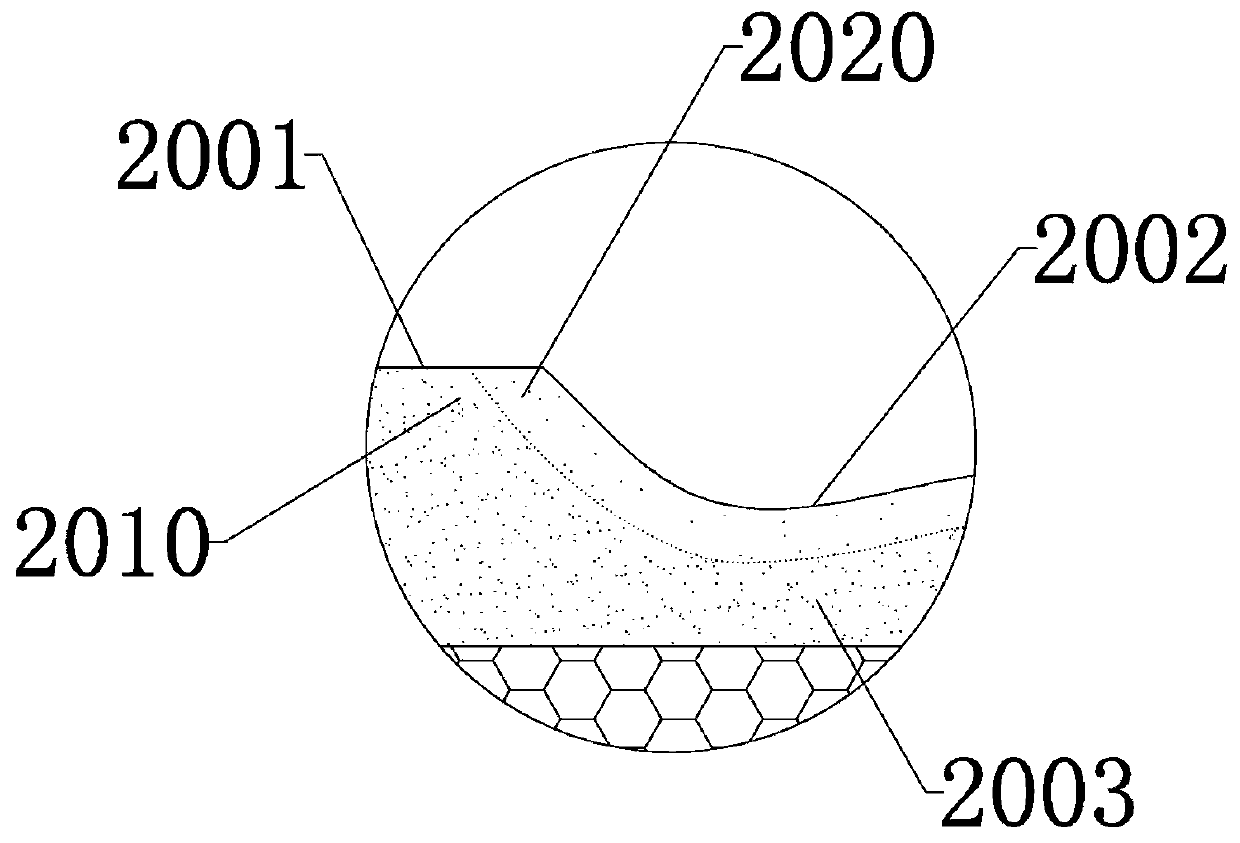

[0037] Such as figure 2 As shown, a wood-textured foam floor includes a foam base 1000 and a hard surface layer 2000 . The hard surface layer 2000 is a three-dimensional concave-convex structure, the convex surface is the first exposed surface 2001 , and the concave surface is the second exposed surface 2002 . The first exposed surface 2001 is formed of the resin of the first color and is substantially parallel to one surface of the foamed base 1000 . The second exposed surface 2002 is formed by the second color resin. The first color resin and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com