Reconfigurable manufacturing system polymorphic configuration optimization method based on tasks

A manufacturing system and configuration optimization technology, applied in the field of processing and manufacturing, to achieve the effect of flexible processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the content of the present invention and the embodiments described in the accompanying drawings.

[0055] The present invention is a task-based polymorphic configuration optimization method for a reconfigurable manufacturing system, which includes the following steps:

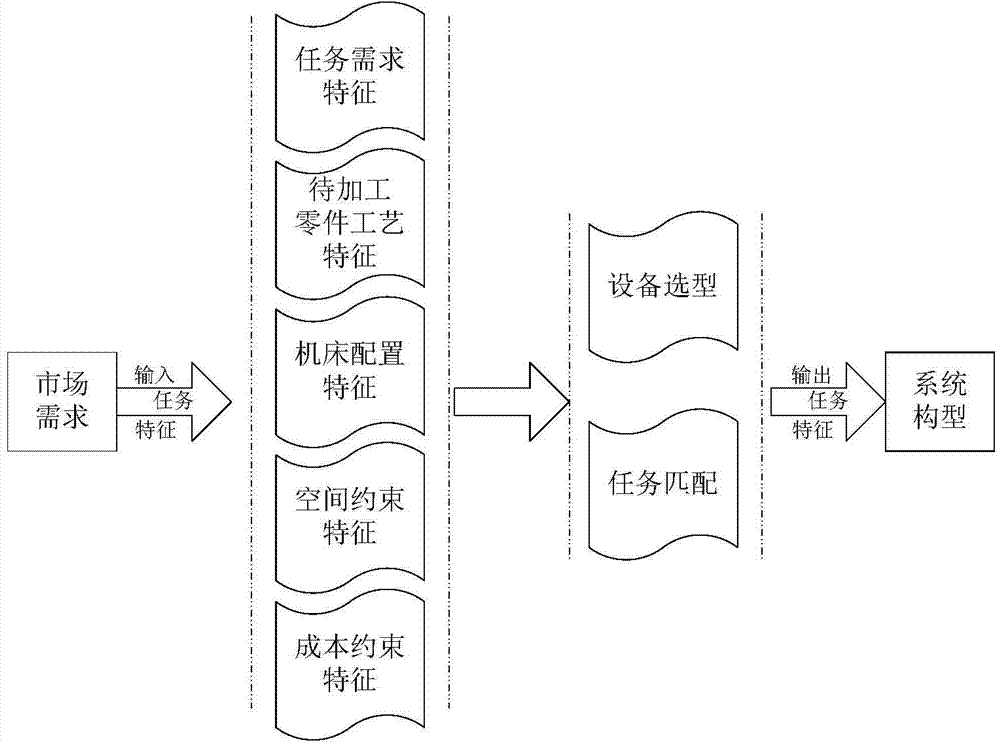

[0056] Step 1: Acquire the characteristic information of the dynamic task, analyze the technological characteristics of the parts to be processed, and determine the priority level of the task.

[0057] Task feature information mainly includes task requirement features, process features of parts to be processed, machine tool configuration features, space constraint features, and cost constraint features.

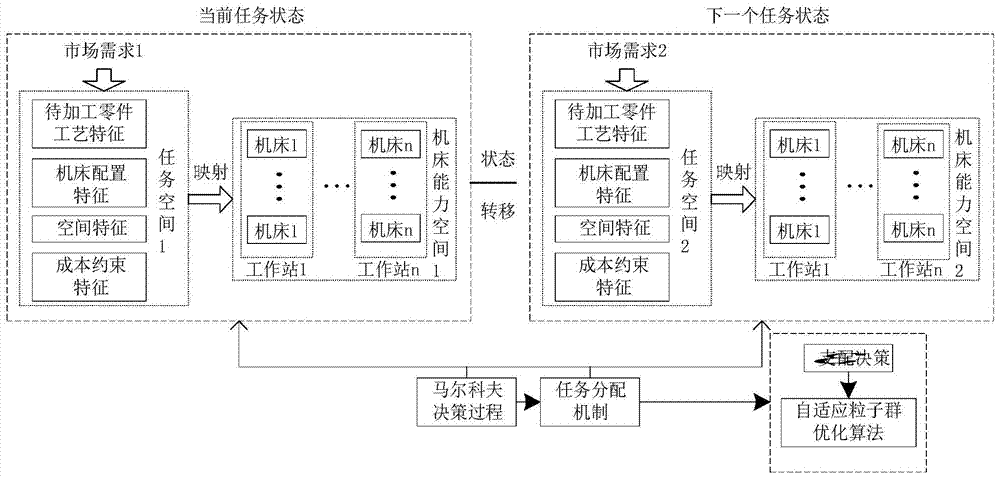

[0058] Step 2, establish a dynamic space model used to describe the process of task state change and a machine tool capability space model used to describe the number of machine tools.

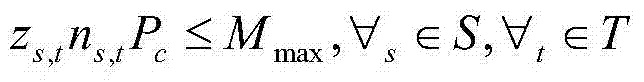

[0059] The state space used to describe th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com