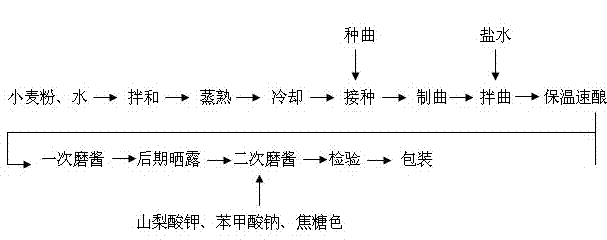

Production process for flour paste

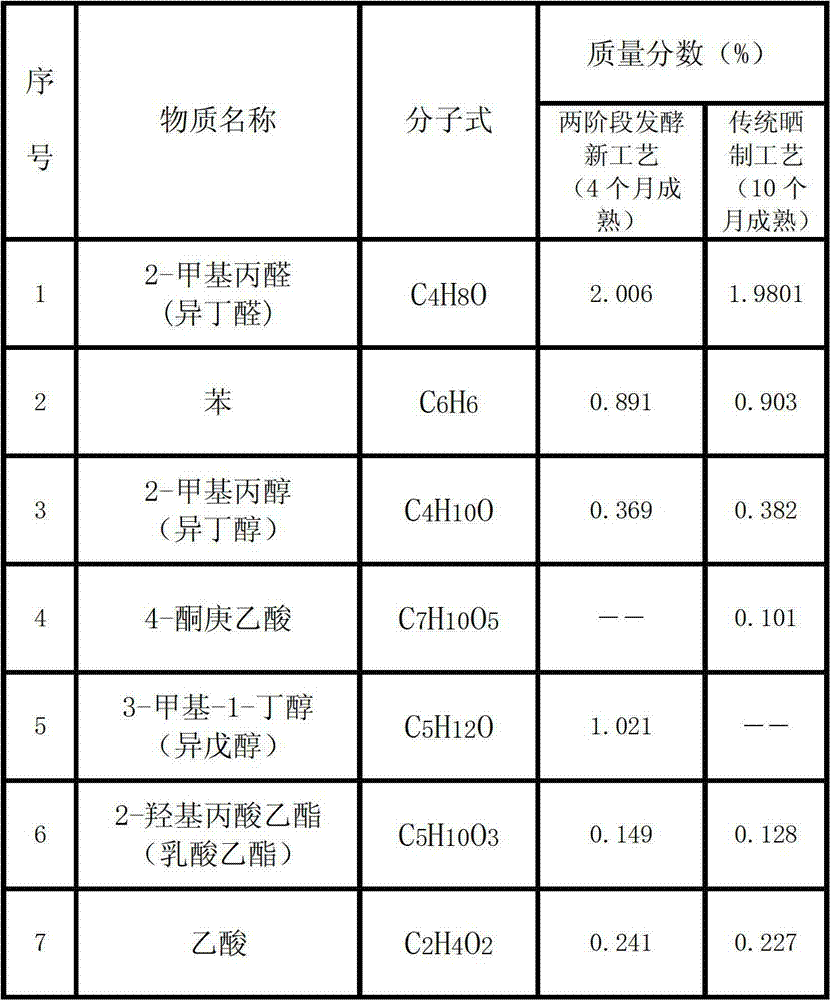

A production process and noodle sauce technology, which is applied in food preparation, application, food science, etc., can solve problems such as failure to meet quality standards, long fermentation time, uncoordinated sauce and ester aromas, etc., to reduce production costs and reduce The effect of capital occupation and adapting to market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 8.0kg of water to 25kg of raw wheat flour and stir evenly, steam it for cooking, and transport the cooked material to the koji pond for cooling. The quality requirements of the clinker: the noodle cake has a prominent aroma of steamed buns, is elastic, and has no sandwich , not sticky to the teeth and slightly sweet when chewing, the reference value of the moisture content of the clinker is 32%, and when the noodle cake is cooled to 40°C, add homemade seed koji at a ratio of 0.4% of the raw material for inoculation. The operation steps of self-made koji seeding are: control the thickness of the koji material into the pond at 280 mm, and require the material layer to be loose, without large lumps, and uniform in thickness. During the static cultivation stage, the temperature is controlled at 35°C. After 10 hours, the koji material starts to heat up, and then ventilation is started to make koji. After 16 hours of cultivation, when the koji material turns white and aggl...

Embodiment 2

[0028]Add pure water to the wheat flour according to the proportion of raw materials, steam it with steam, and transport the material to the koji pool for cooling. The thickness of the cooling is 30cm; Add the kind of koji, and mix evenly, and inoculate; put the koji into the koji pool, the thickness of the koji pool is 300 mm, the material layer is loose, there are no large lumps, and the thickness is uniform, and the temperature in the static cultivation stage is controlled at 34 ℃, at 11 hours, raise the temperature of the koji material and start ventilation to make koji. Cultivate it for 17 hours. When the koji material turns white and agglomerates and the temperature cannot be lowered to the quality control temperature with circulating air, turn the koji. The temperature of the koji material in the later stage is controlled at 34 ℃; when the mycelium of the koji material is full and yellow-green spores are grown, it means that the koji has been fermented and can be produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com