Evaluation method for machine beam design scheme by using fuzzy analytic hierarchy process

A technology of fuzzy hierarchical analysis and design schemes, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as machine tool beam structure design schemes that do not consider cost and processing efficiency, and achieve shortened development cycle and easy programming The effect of improving the systemization and evaluation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

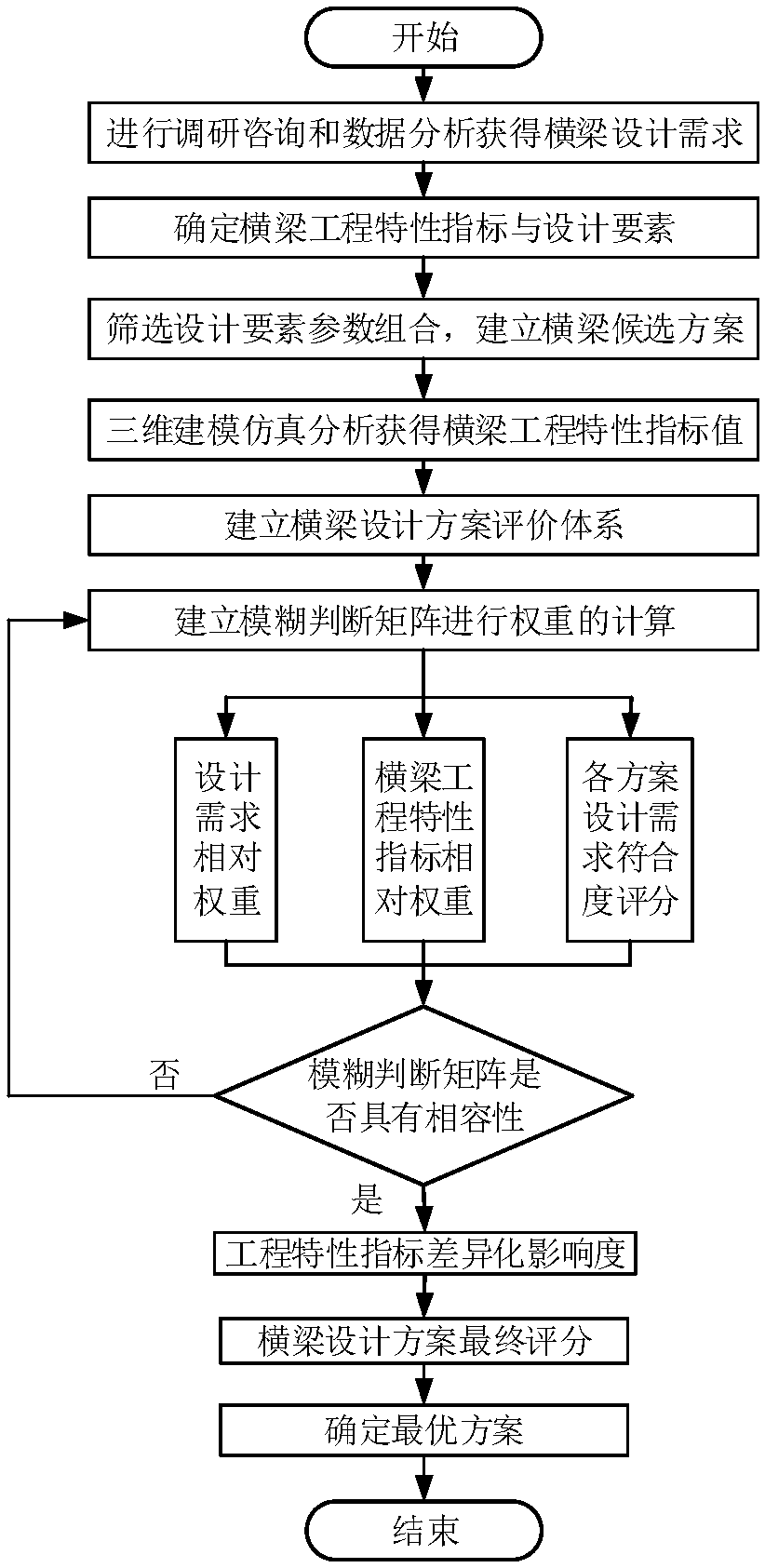

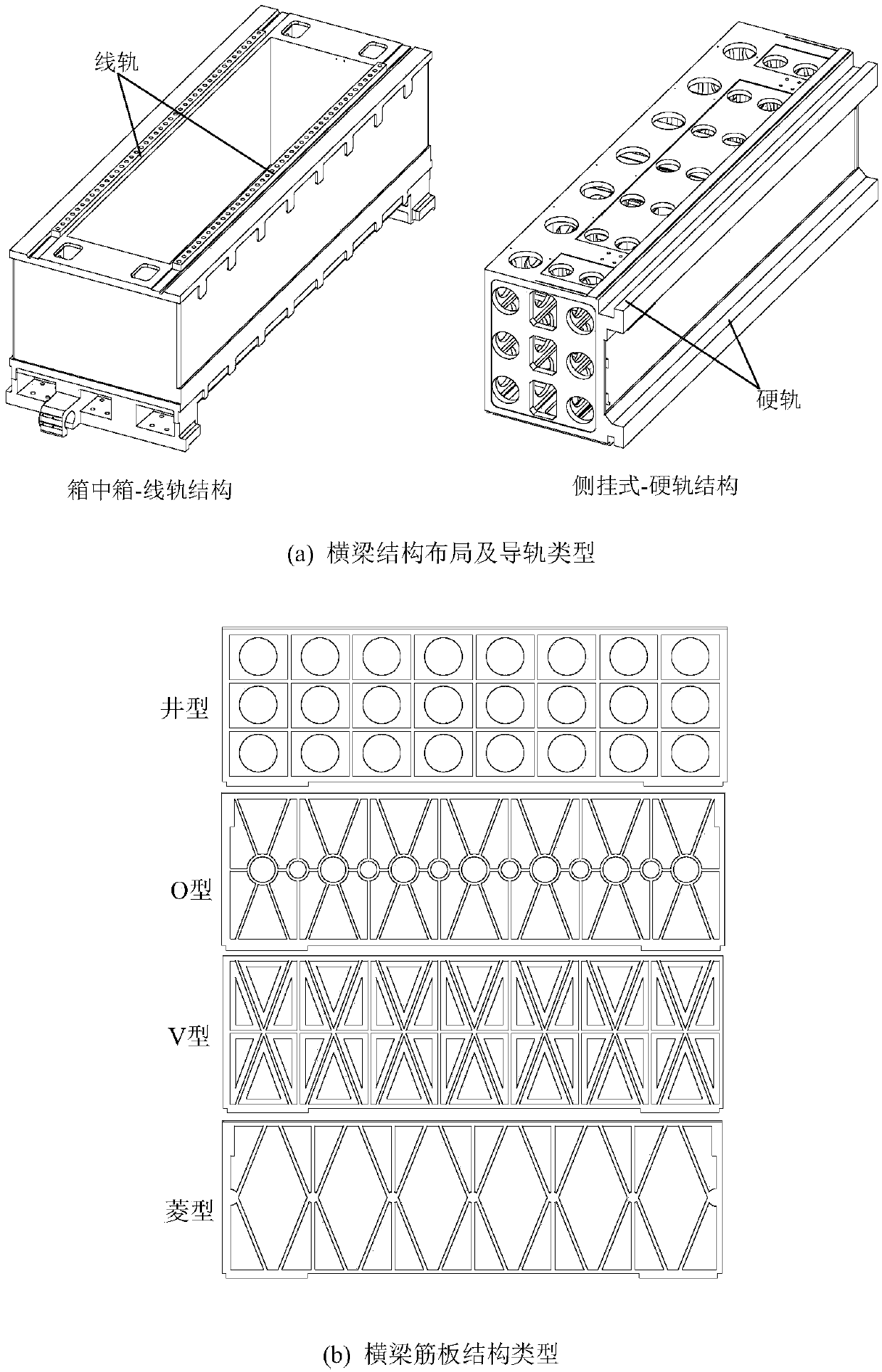

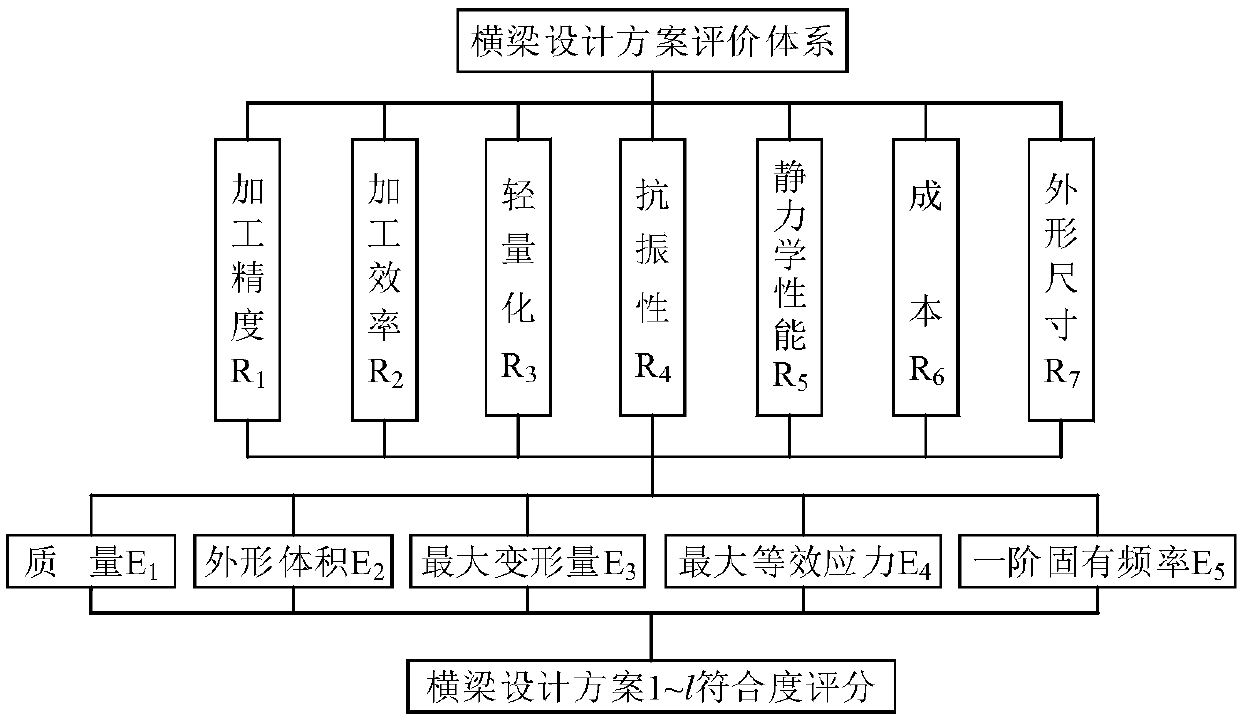

[0057] The present invention takes the evaluation of the beam design scheme of the bridge type gantry milling machine as an example, and the implementation process is as follows figure 1 shown. On the basis of research and consultation and internal data analysis, the requirement of the beam design scheme is obtained as the machining accuracy R 1 , Processing efficiency R 2 , lightweight R 3 , vibration resistance R 4 , Static performance R 5 , cost R 6 , Dimensions R 7 , determined by beam mass E 1 , external volume E 2 , maximum deformation E 3 , the maximum equivalent stress E 4 , the first-order natural frequency E 5 As the evaluation index of beam engineering characteristics, the design elements forming beam design plan are beam structure layout, rib structure, rib thickness, and guide rail type, such as figure 2 (a) and (b) shown. The combination of design elements was screened, the candidate scheme of the beam was determined, and the three-dimensional modeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com