Manufacture process of disposable bowl cover and bowl cover made by same

A production process, one-off technology, applied in textile and papermaking, closing, pulp beating methods, etc., can solve the problems of high energy consumption, large energy consumption, difficult to promote, etc., and achieve the effect of saving energy consumption and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

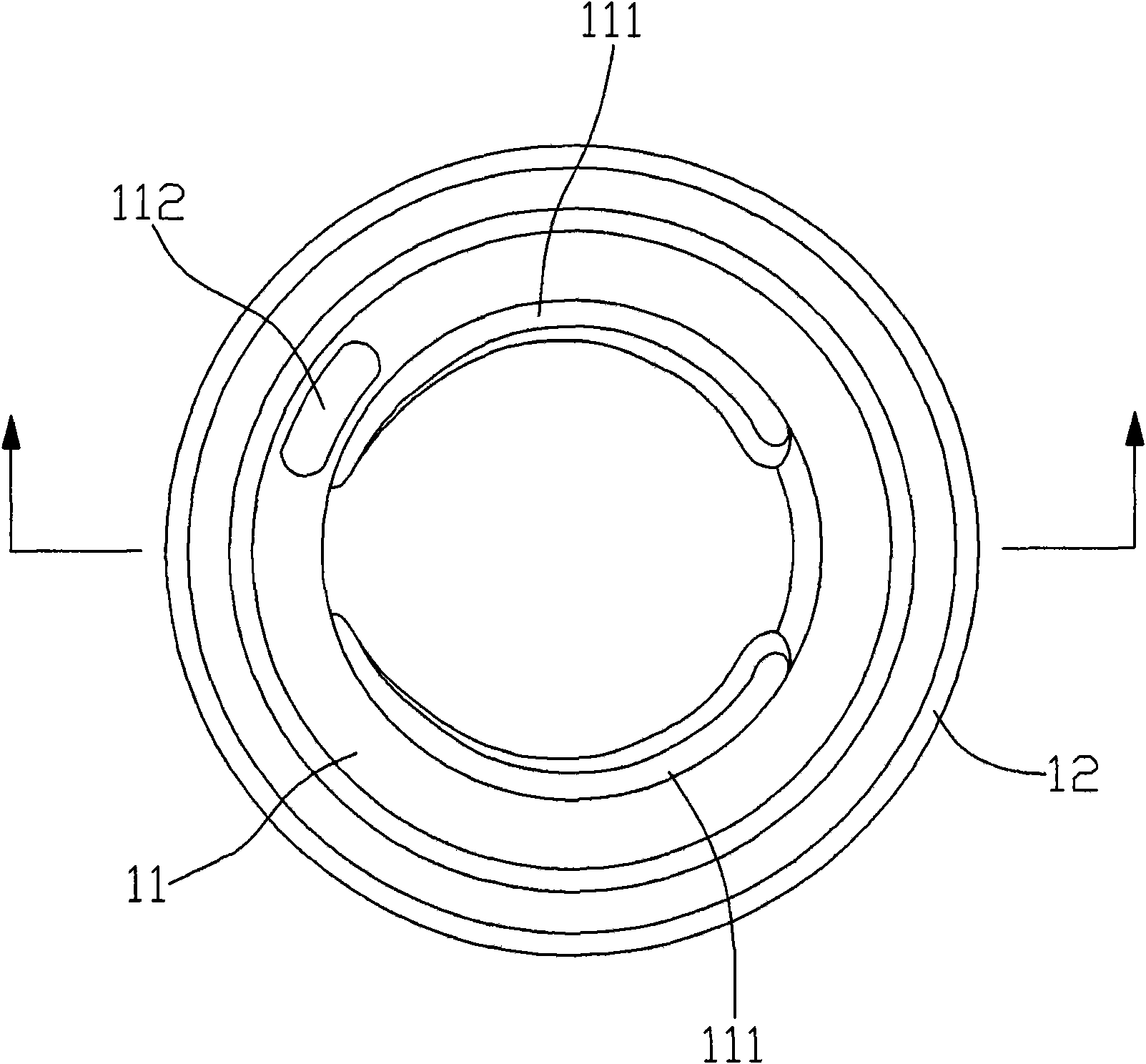

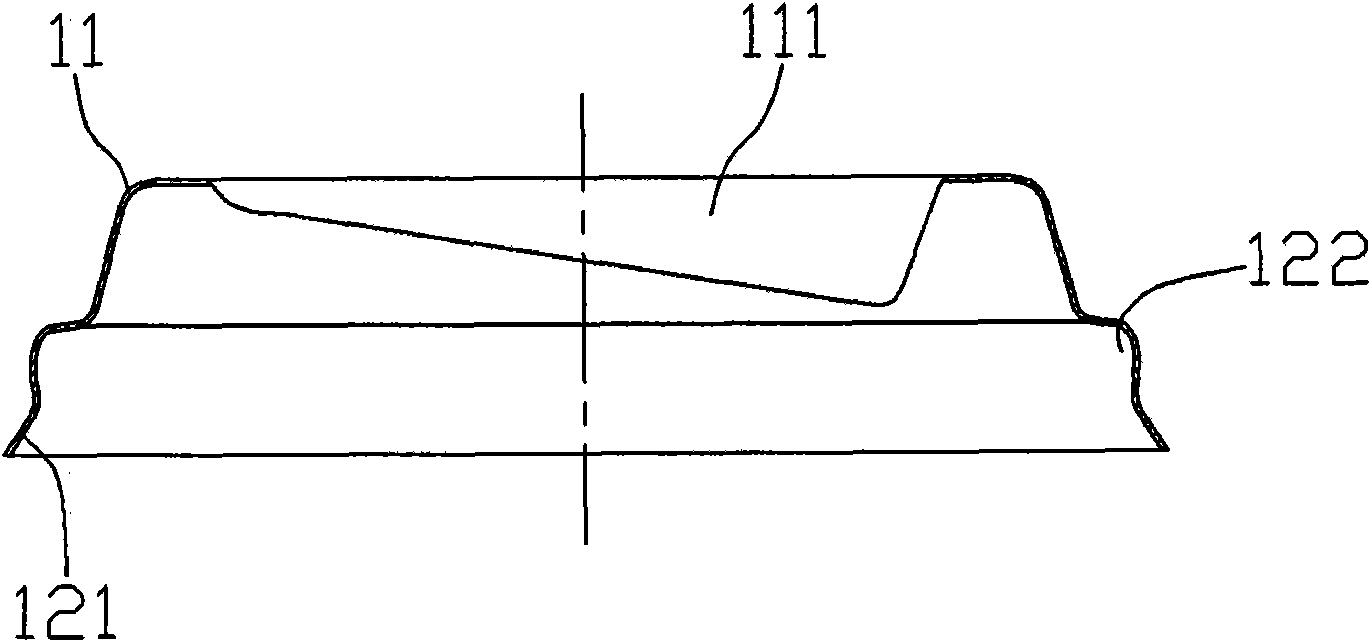

[0019] The present invention is further described below: the manufacturing process of the disposable cup cover, which is characterized in that: the specific steps of the process are raw material beating-batching-molding-molding-hot-pressing-trimming and punching-pressing the inverted hook groove, wherein ,

[0020] 1. Raw material beating: the raw material used is mainly bagasse paddle board supplemented with a small amount of wood pulp and bamboo pulp, and is beaten with water by a beater, with a beating concentration of 4-6%;

[0021] 2. Ingredients: add water to the thick slurry prepared in step 1 until the paper fiber concentration is 0.5-1%, then add waterproofing agent and wet strength agent to increase product strength, the amount of waterproofing agent added is the mass of paper fiber 3-5%.

[0022] 3. Compression molding: After batching, press the mold directly to form a wet billet with a moisture content of 70%±5%;

[0023] 4. Hot pressing and shaping: transfer the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com