Fully-automatic thermal-formation paper-plastic package technology and packing machine

A packaging technology, thermoforming technology, applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of increasing the labor intensity of operators, not being able to adapt to modern production, and low work efficiency, so as to achieve a high degree of automation and work The effect of high efficiency and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

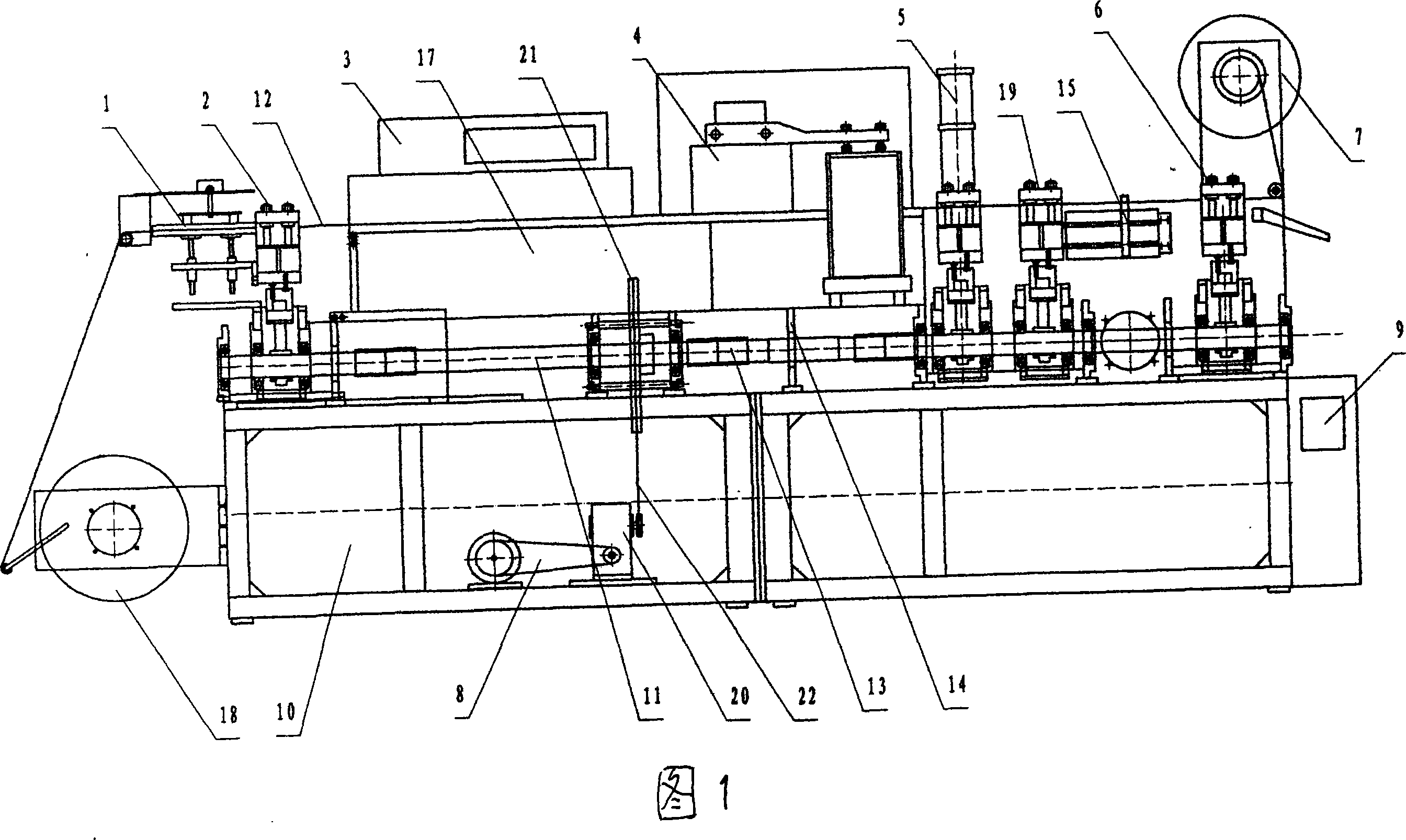

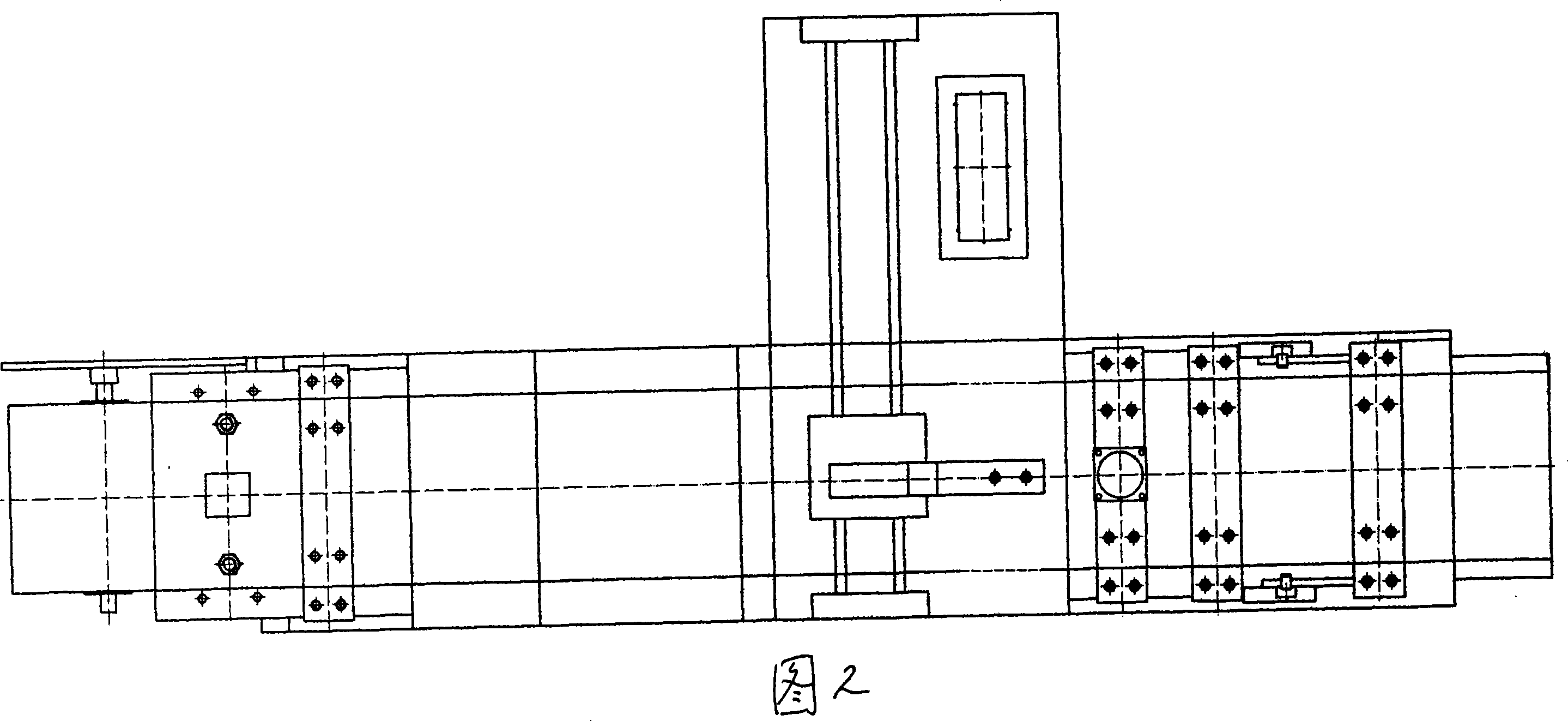

[0010] The full-automatic thermoforming paper-plastic packaging process of the present invention is: first, the plastic coil is unrolled by an unwinding device to form a plastic sheet; Heating and softening, forming processing; then it is automatically sent to the filling device through the flat plate to fill the required materials in the formed plastic sheet, and then automatically sent to the sealing device through the flat plate to cover the plastic sheet with paper ( or film, aluminum sheet) and seal the paper (or film, aluminum sheet) in the sealing device, and finally process it into a paper-plastic packaging product through a punching device; the automatic transmission of the paper-plastic packaging material and its waste The collection is controlled by the feeding device and the waste rewinding device. The heating device, the forming device, the filling device, the sealing device, the sealing device, the feeding device, and the punching device are sequentially installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com