Molded pulp container cover with clamping tenon, mold for manufacturing container cover and manufacturing method

A technology of pulp molding and mold making, which is applied in the field of pulp molding container lids with tenon and its manufacturing molds and manufacturing, can solve the problems of increasing product cost, incision pulp stubble, stubble unhygienic, etc., to achieve The effect of improving production efficiency, upgrading grades and saving working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

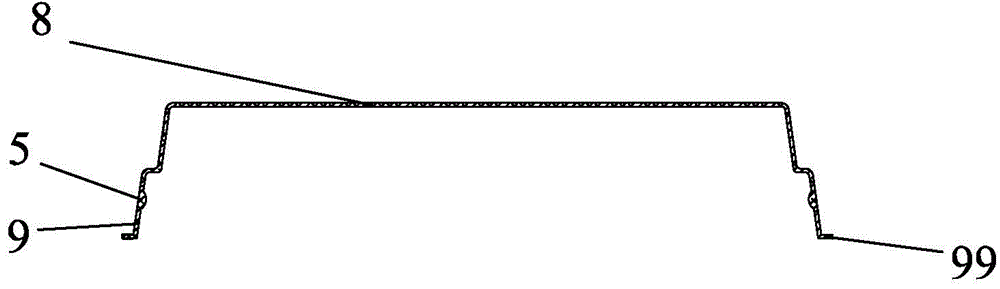

[0032] Such as figure 1 The pulp molded container lid with tenons shown in the present invention includes a lid top 8 in the middle and a lid mouth 9 that is placed outside the lid top and slopes downwards. A protruding tenon 5; the protrusion height of the tenon 5 is 0<h≤1 mm. In addition, the outer side of the cover opening 9 is a smooth surface.

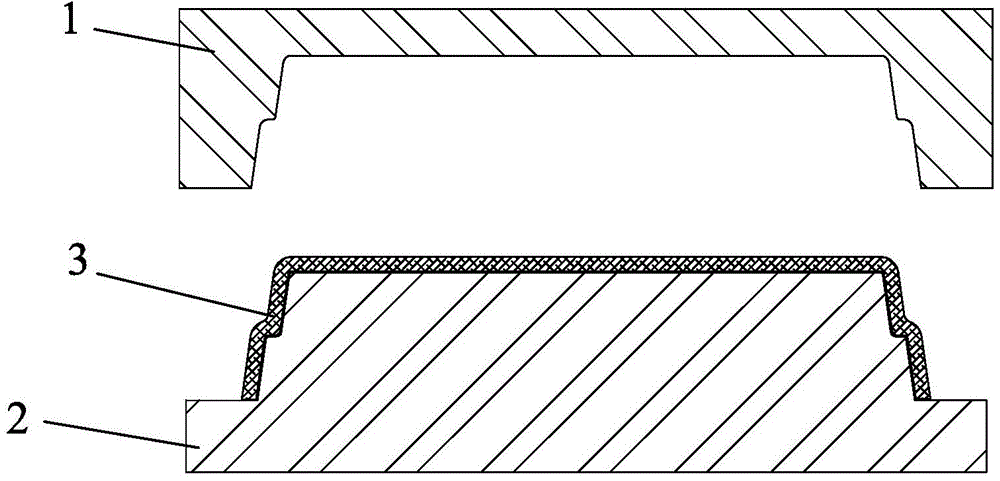

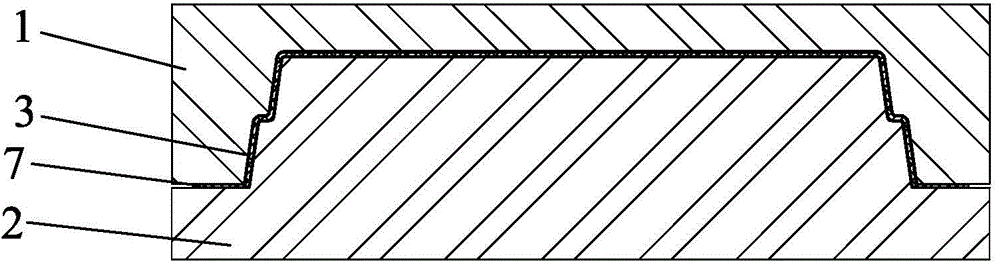

[0033] Usually, forming the above-mentioned container lid requires a concave mold 1 and a male mold 2 to form the concave structure of the container lid. noodle. In addition, an arc-shaped groove 4 is provided in the circumferential direction of the middle part of the tapered surface of the punch 2, and the depth of the arc-shaped groove 4 is 0

[0034] In order to improve the structural strength of the carfalcon, the present invention adopts a closed mold, which are respectively Figure 4-5 as well as Figure 6-8The mold processing method shown.

[0035] in, Figure 6-8 The retaining ring 6 is set on the punch (or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com