Patents

Literature

60results about "Sliding roofs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

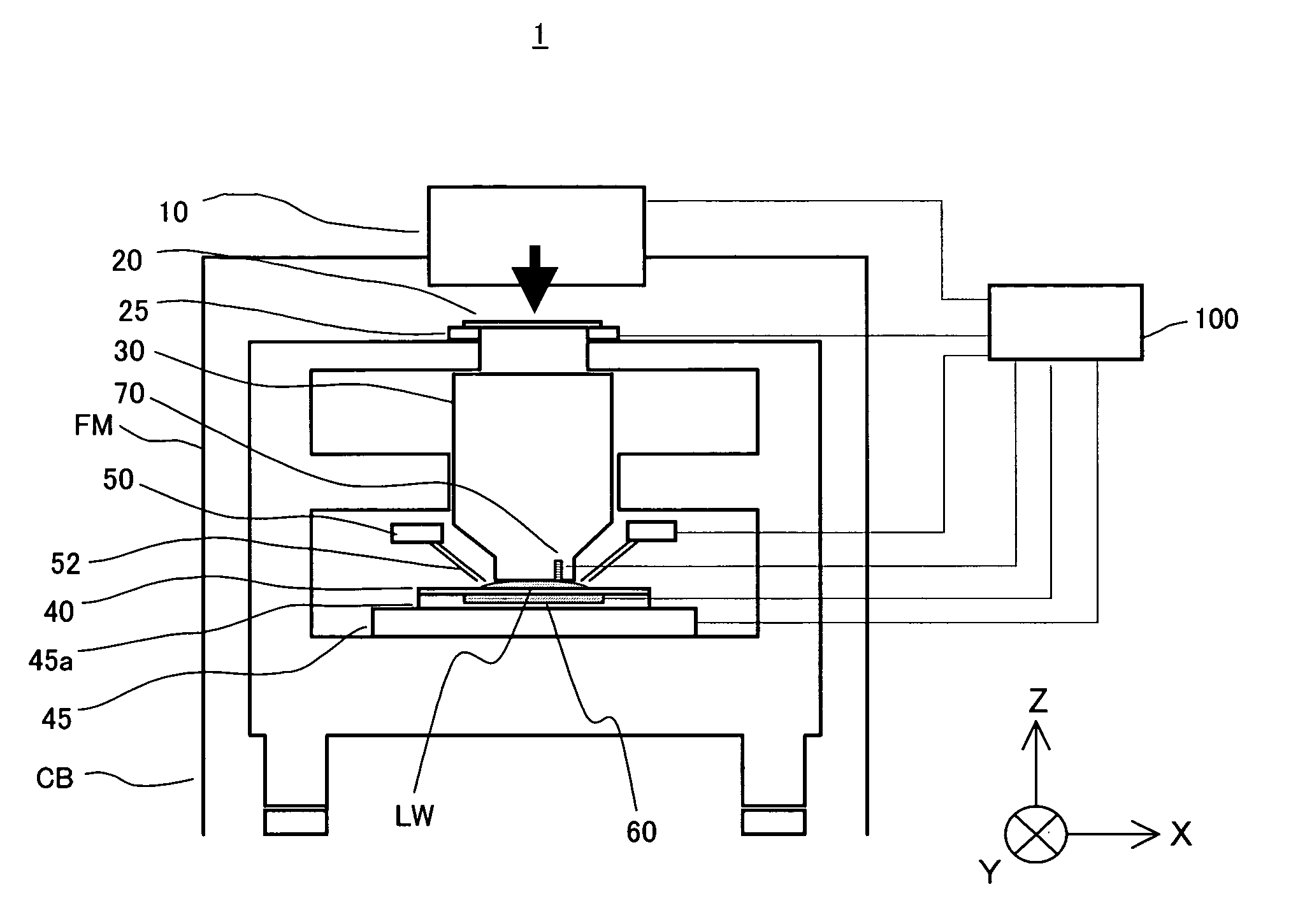

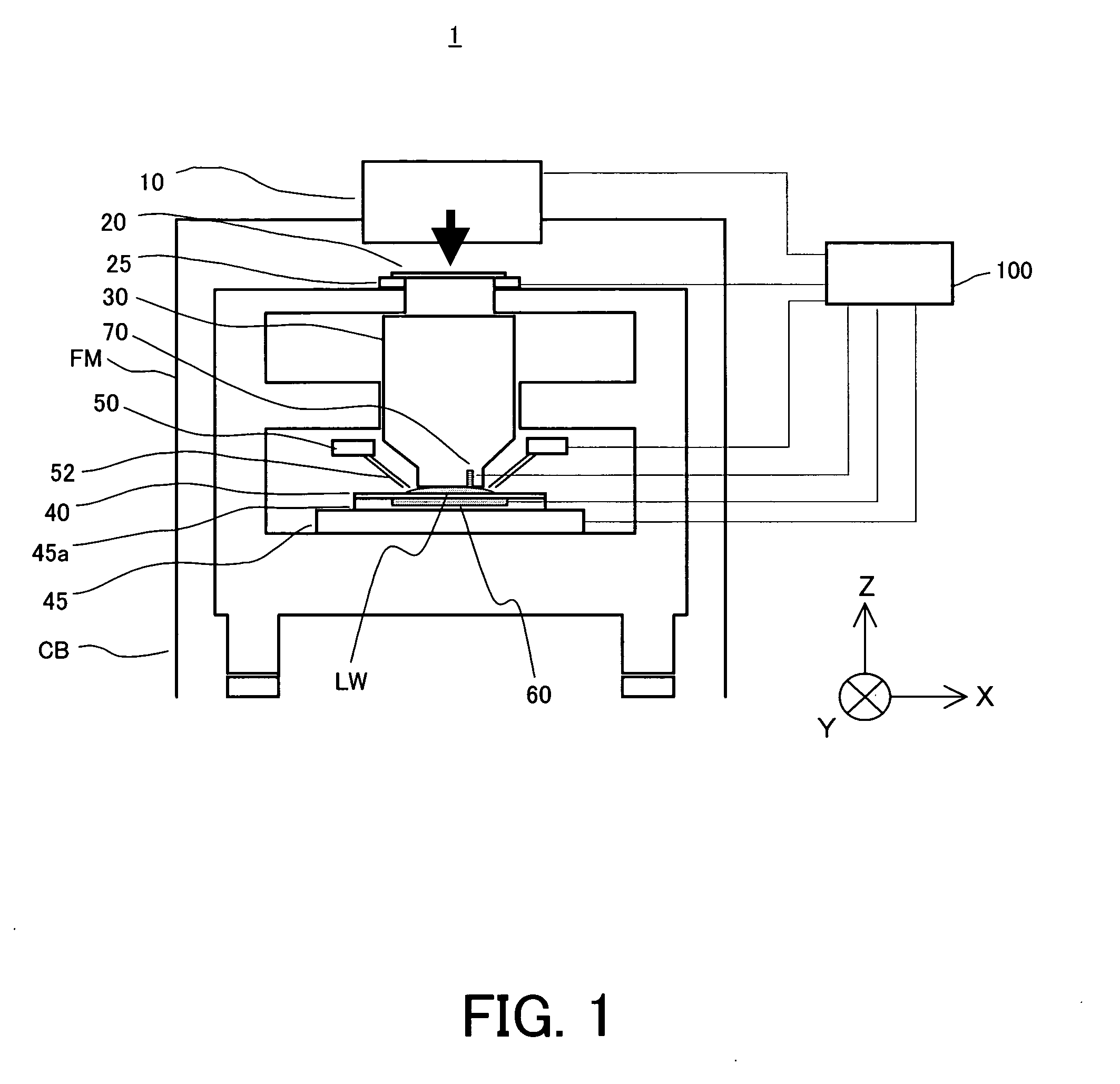

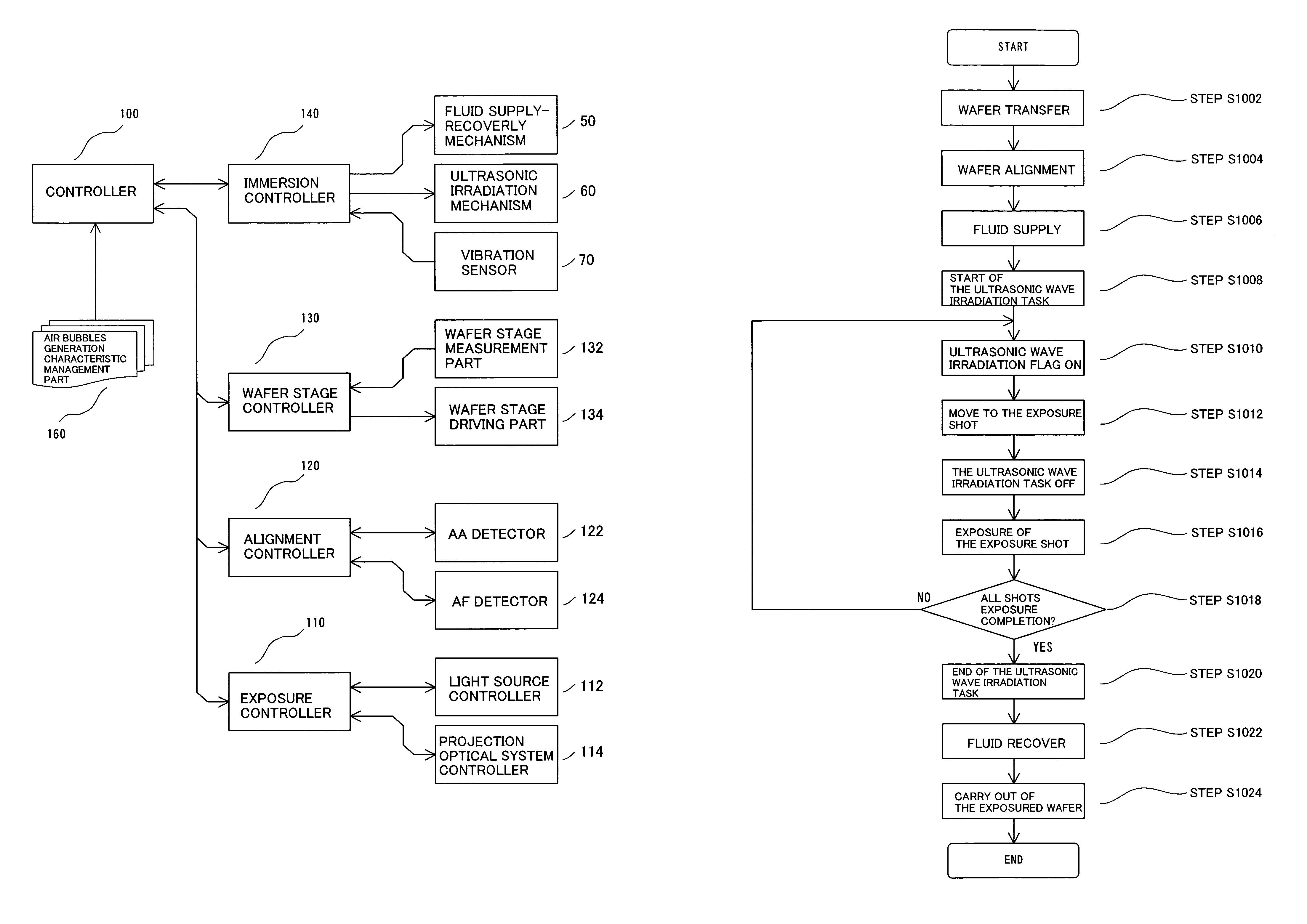

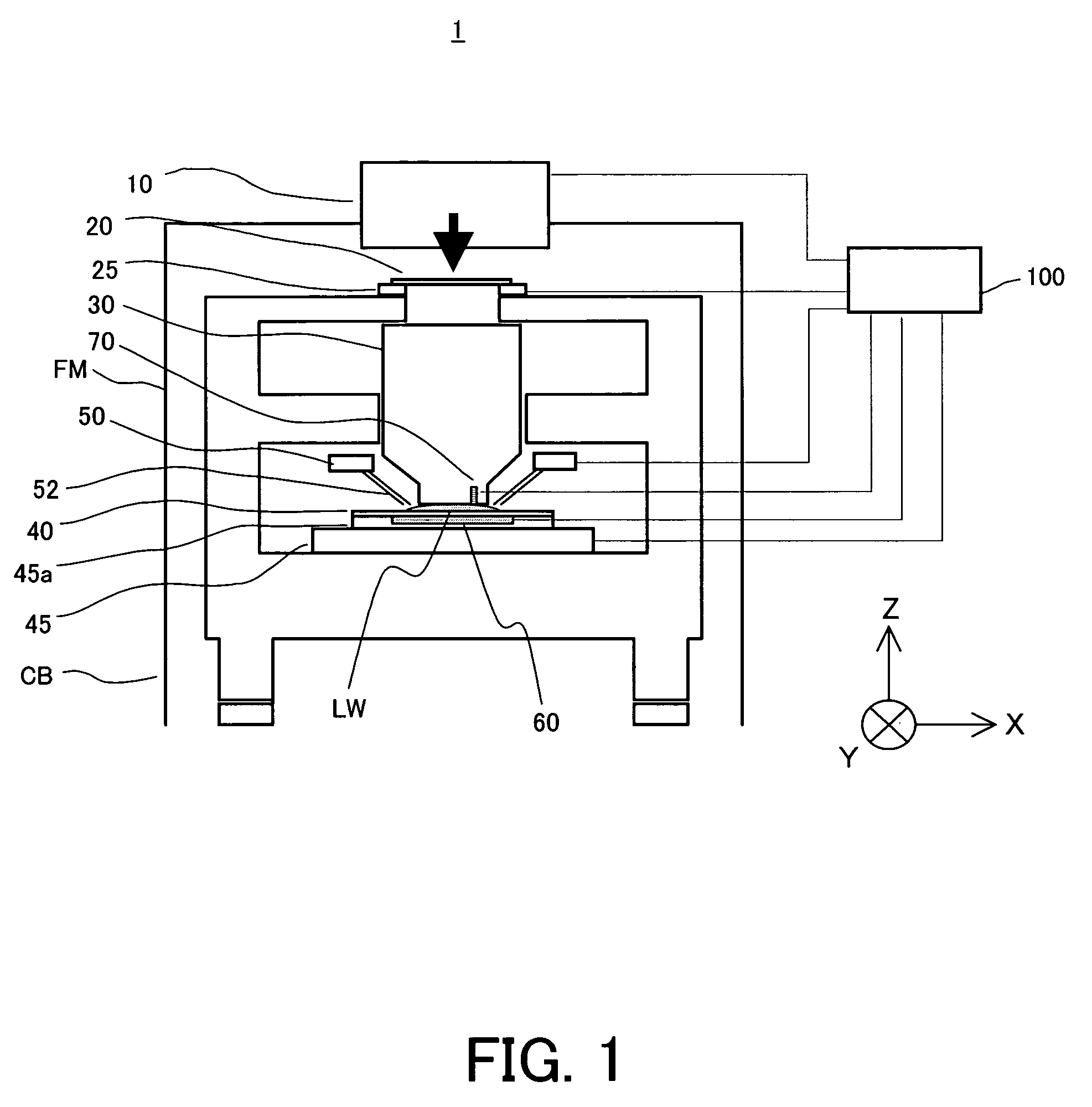

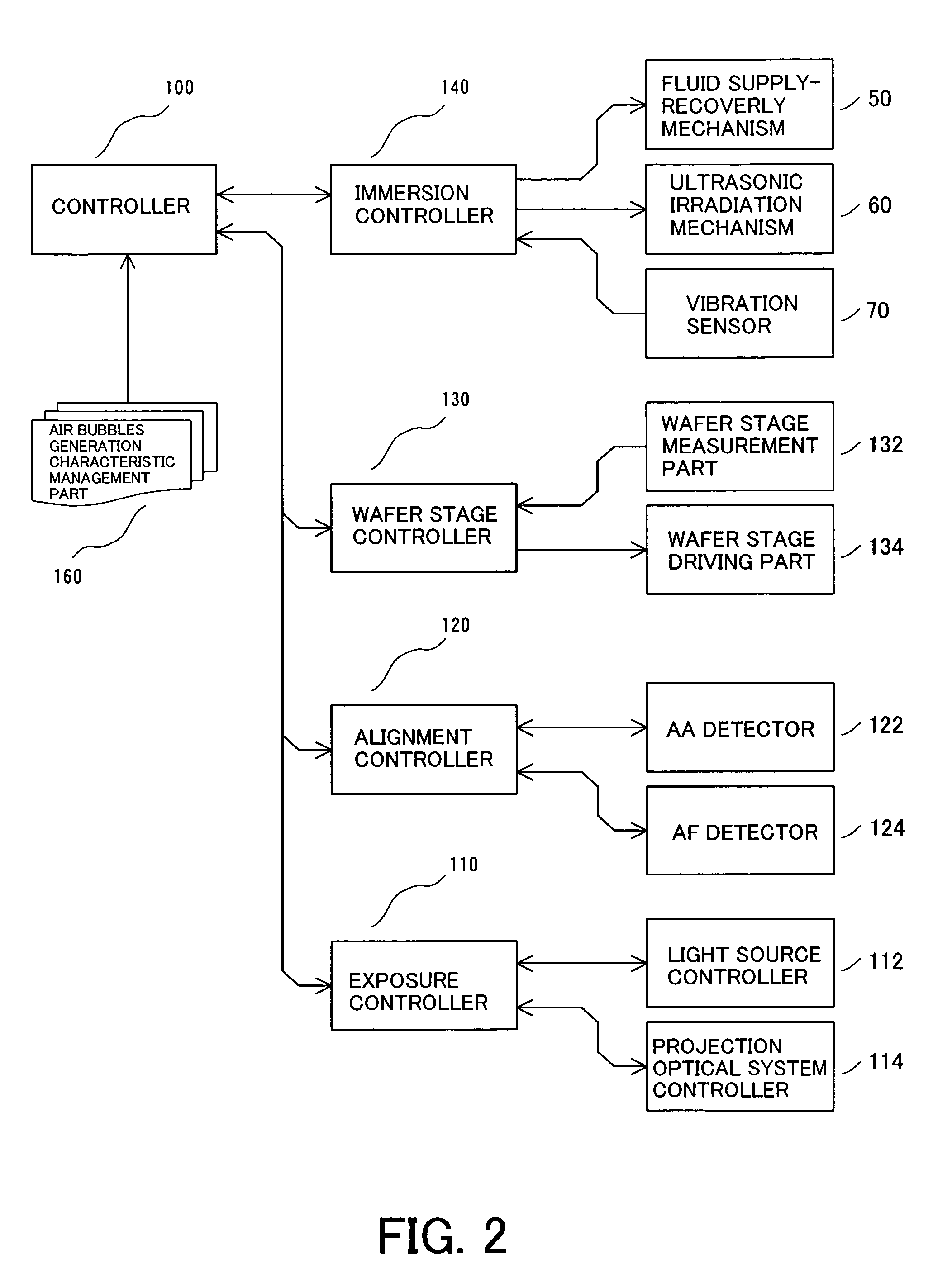

Exposure apparatus and method

InactiveUS20050213065A1Efficient removalInhibit deteriorationRailway vehiclesSemiconductor/solid-state device manufacturingReticleOptics

An exposure apparatus includes a projection optical system for projecting an image of a pattern of a reticle onto an object, via a fluid that is filled in a space between said projection optical system and the object, a vibrator part for vibrating at least one of the fluid, the object, and the projection optical system, and a controller for controlling the vibrator part so that the vibration of at least one of the fluid, the object, and the projection optical system becomes a tolerance during a processing of the object.

Owner:CANON KK

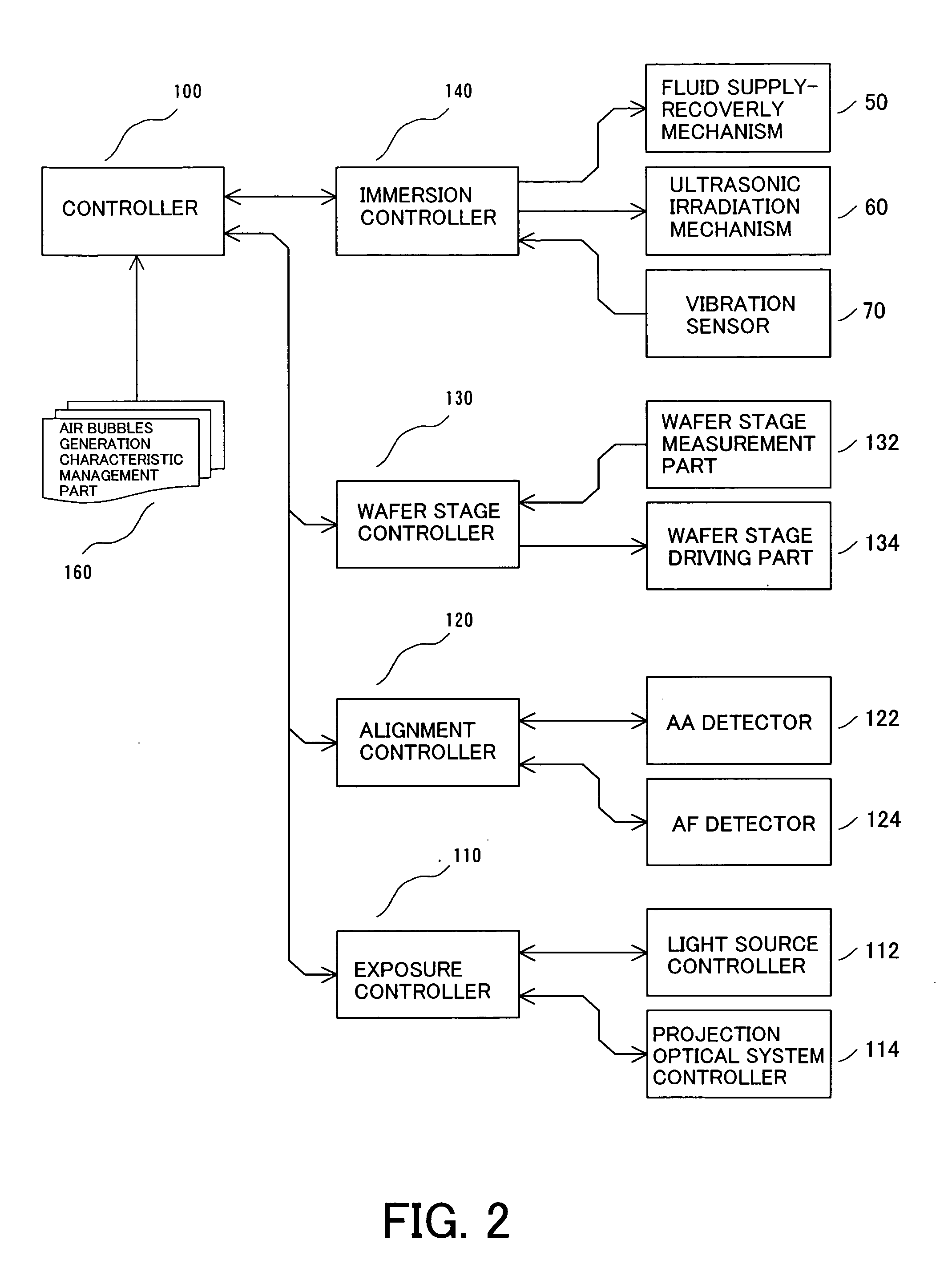

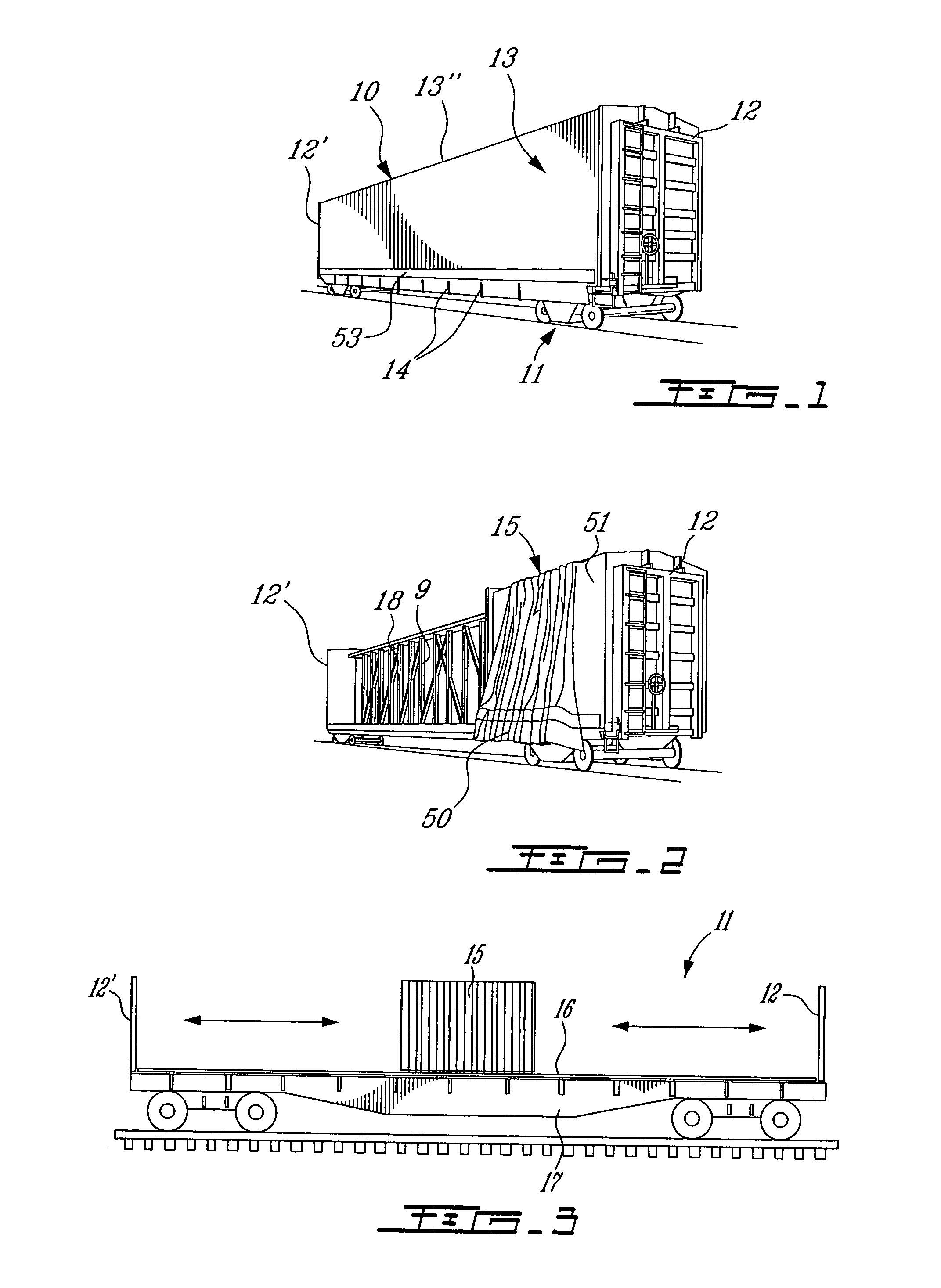

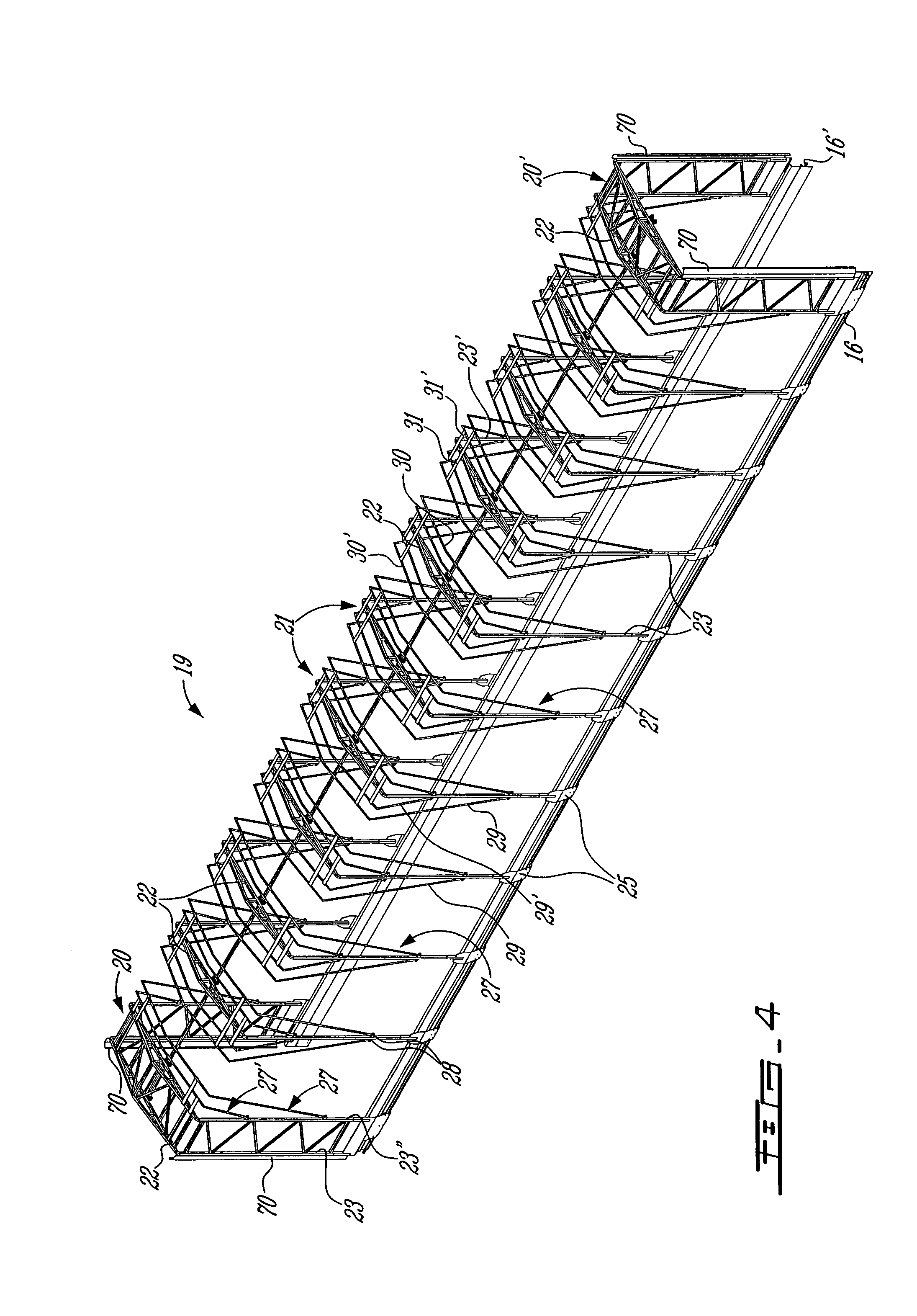

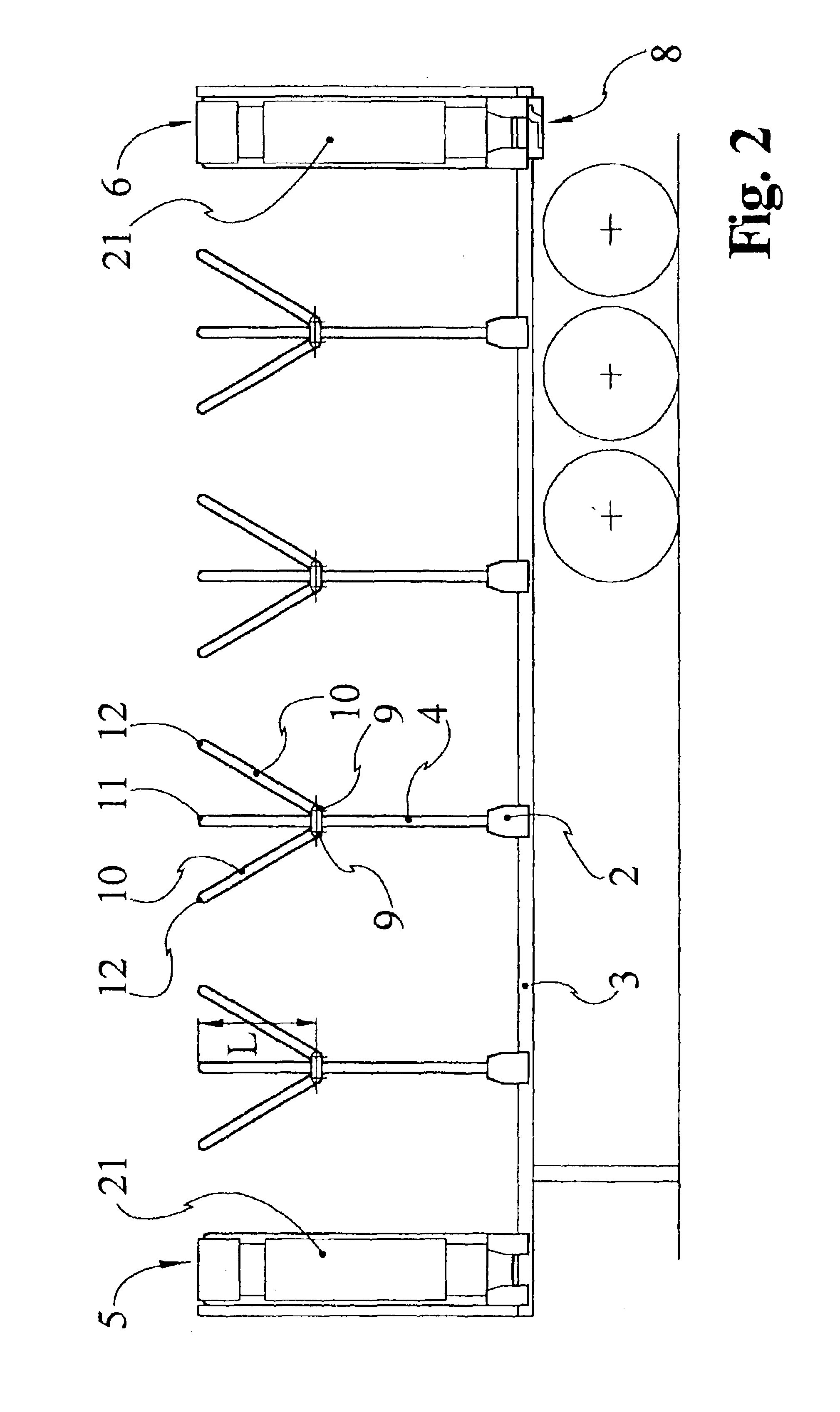

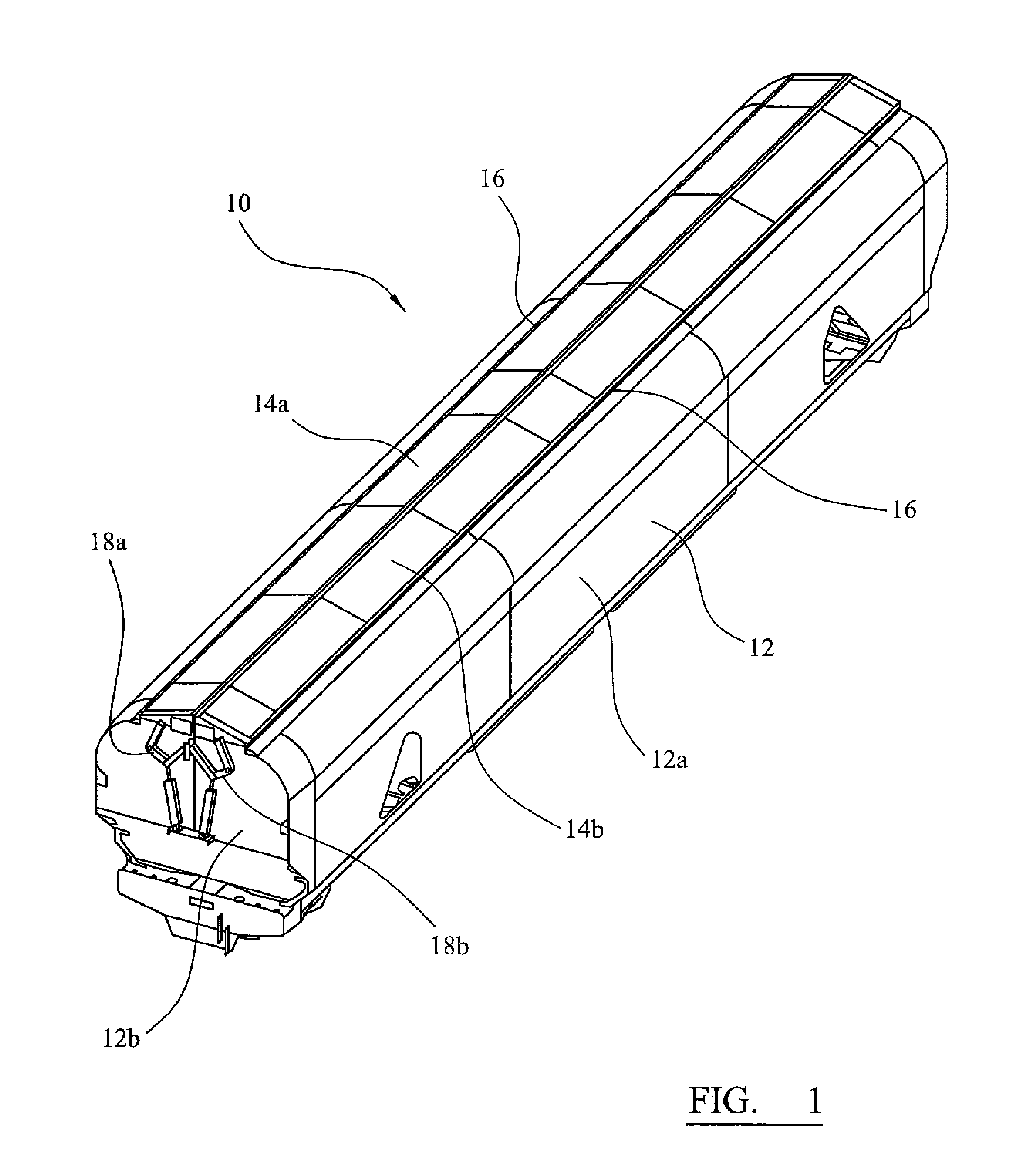

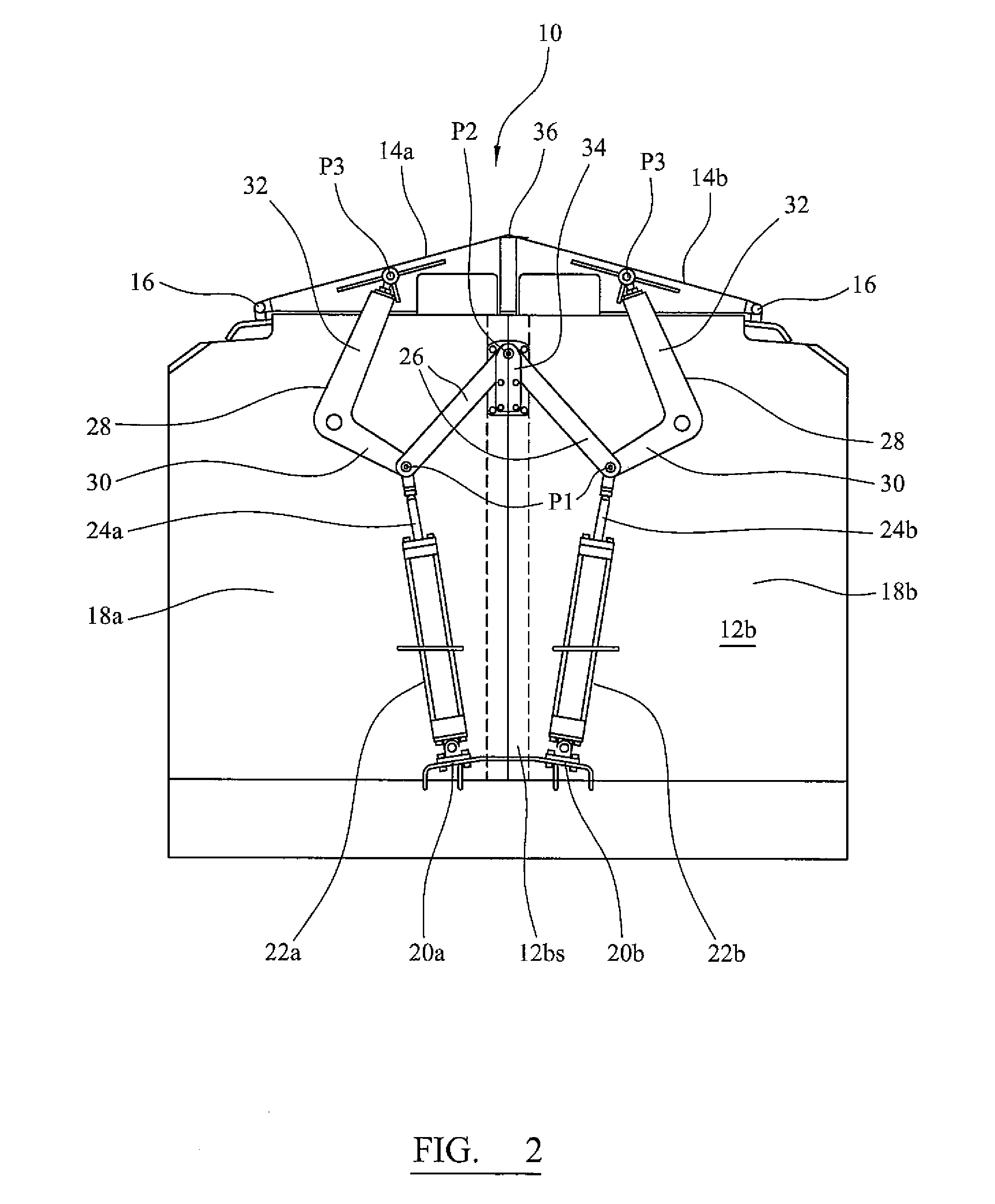

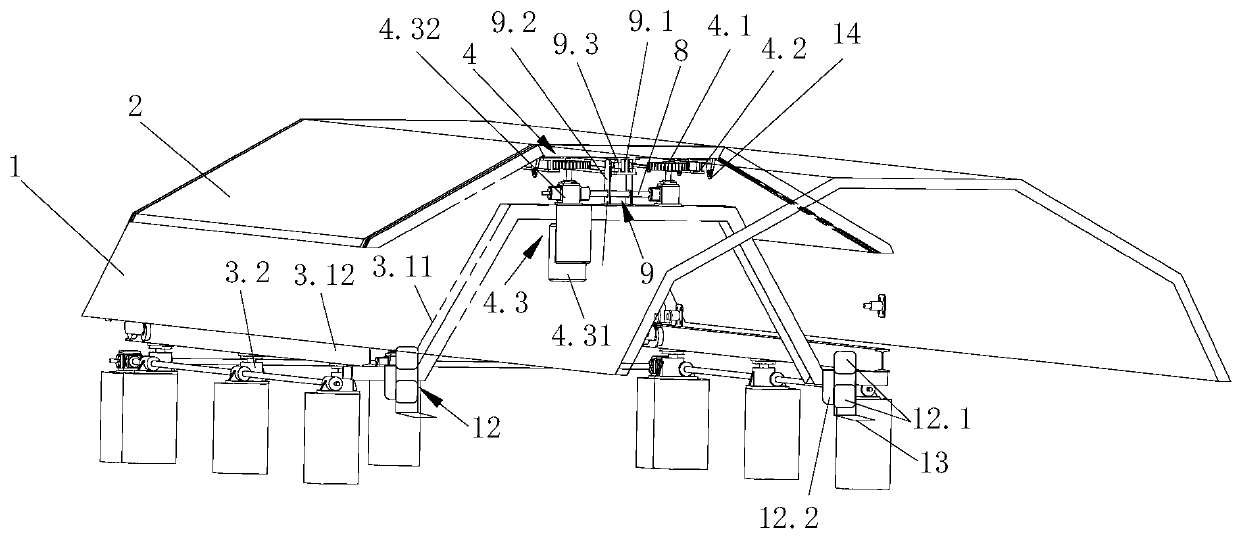

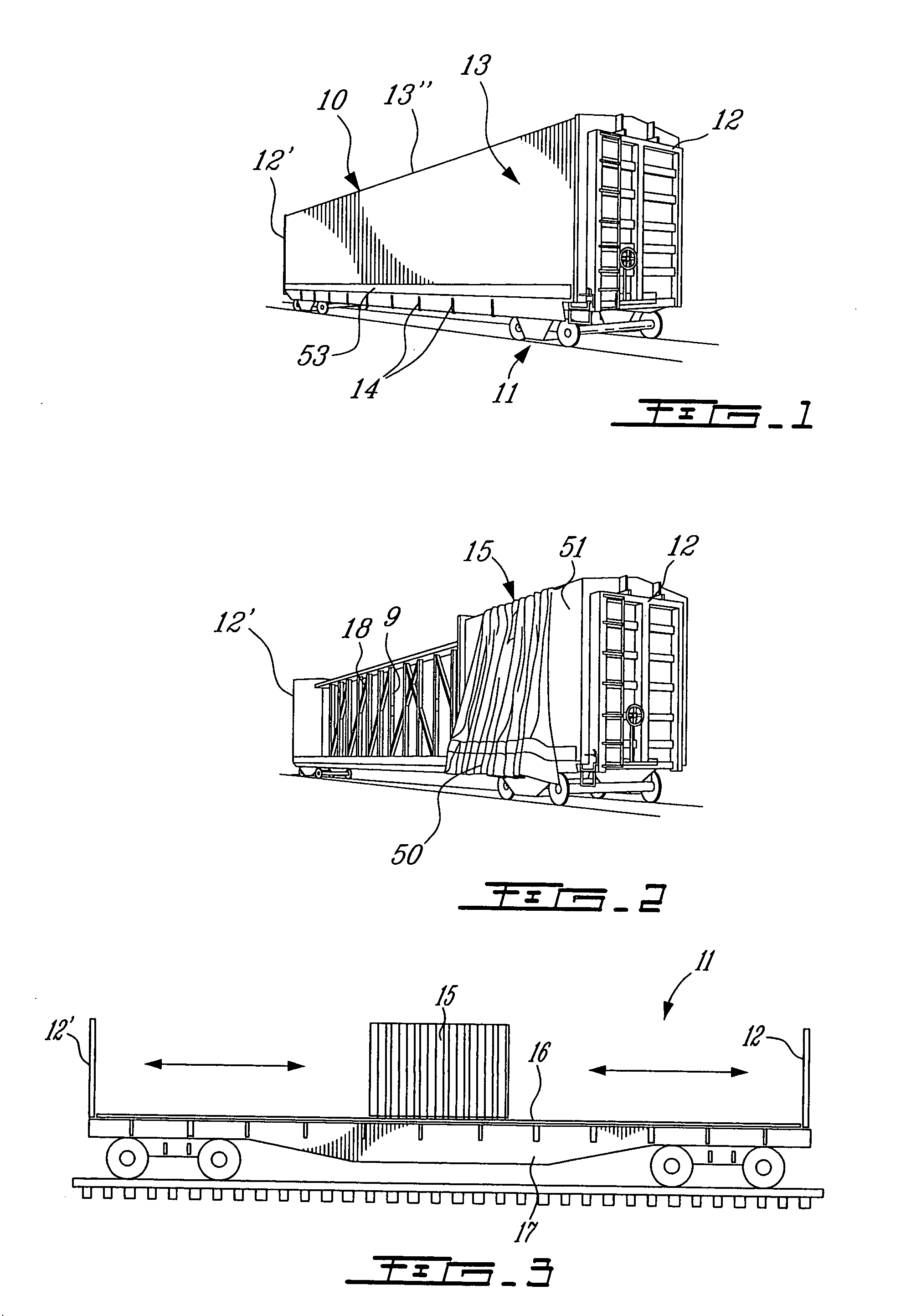

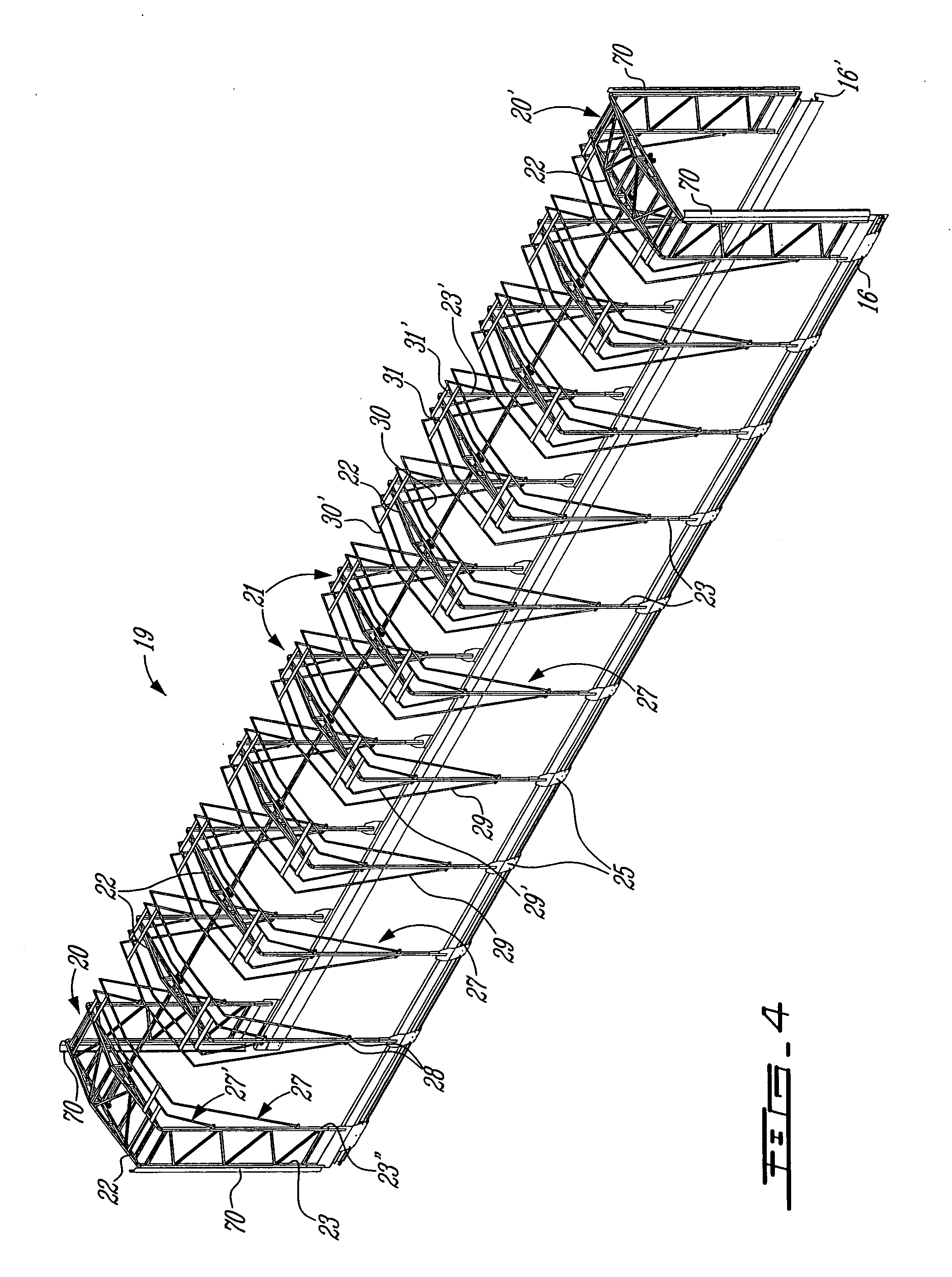

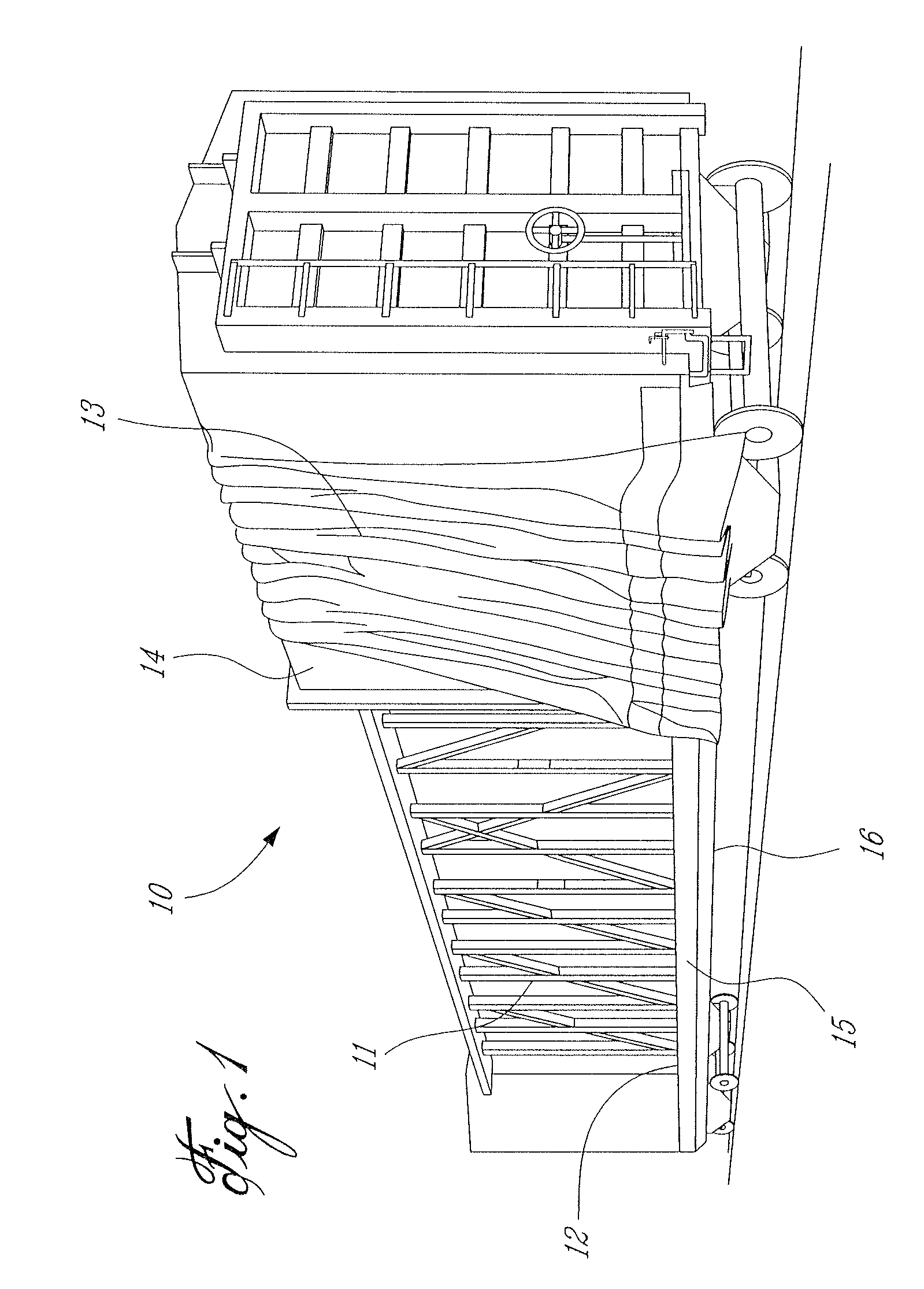

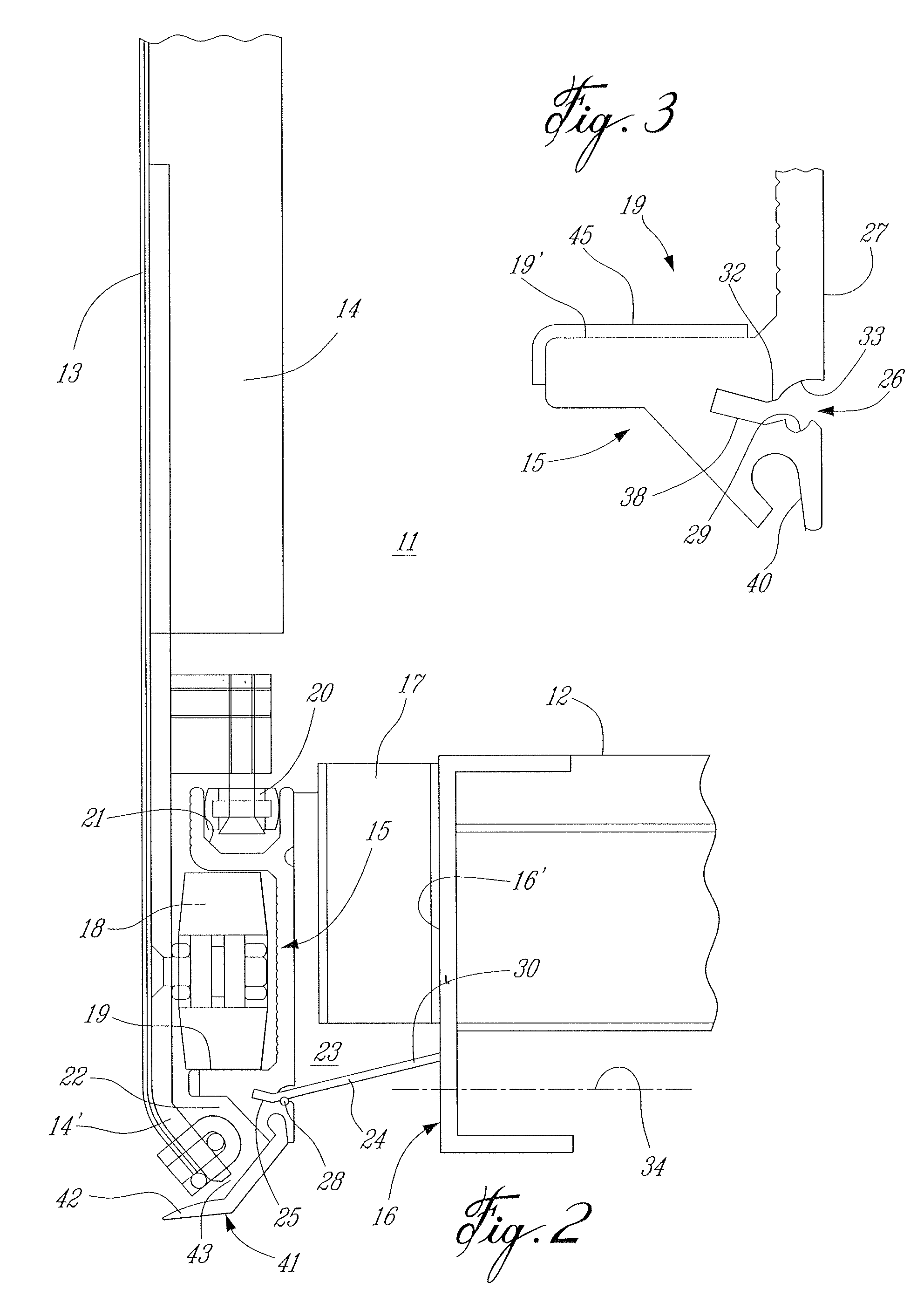

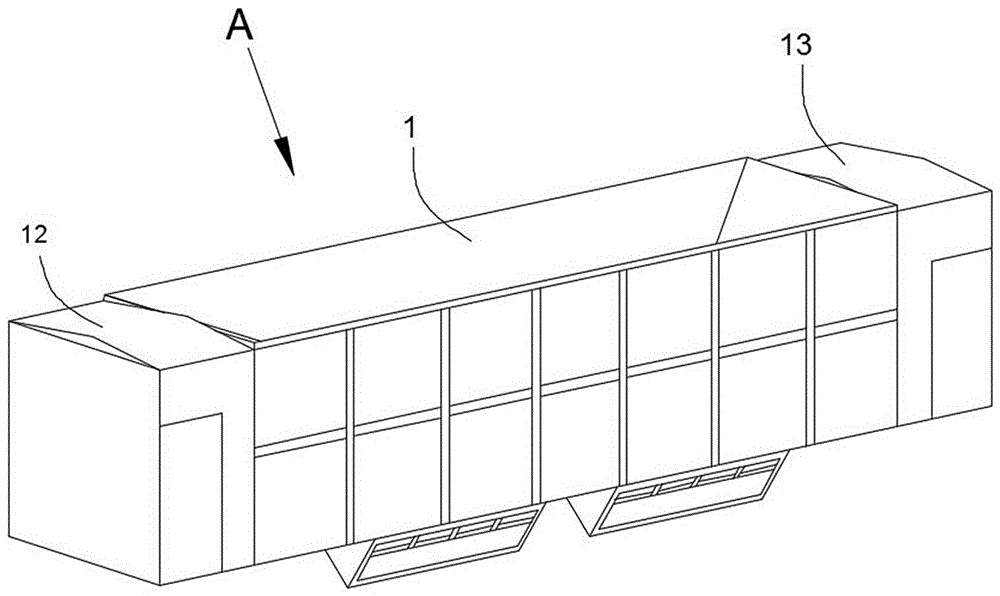

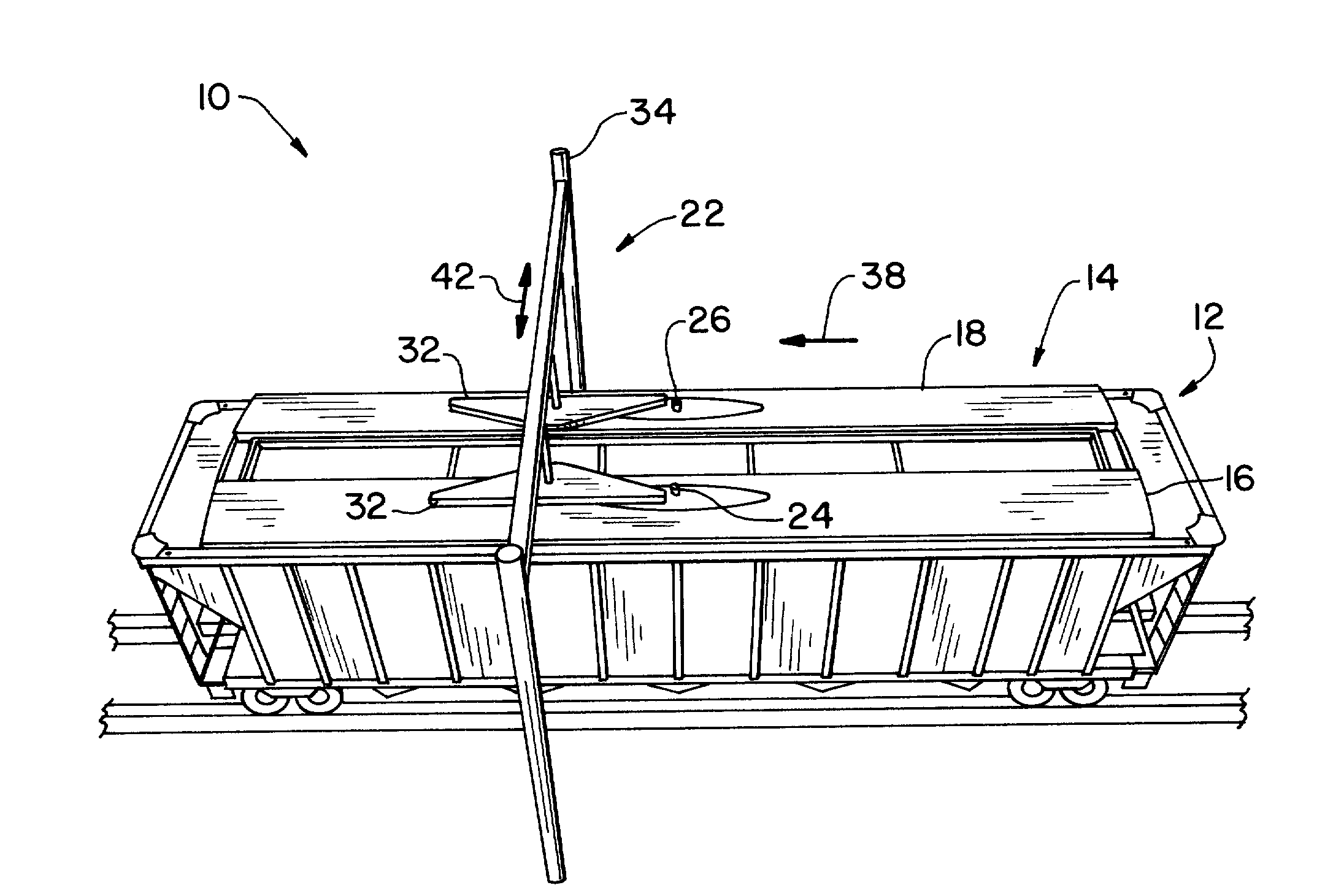

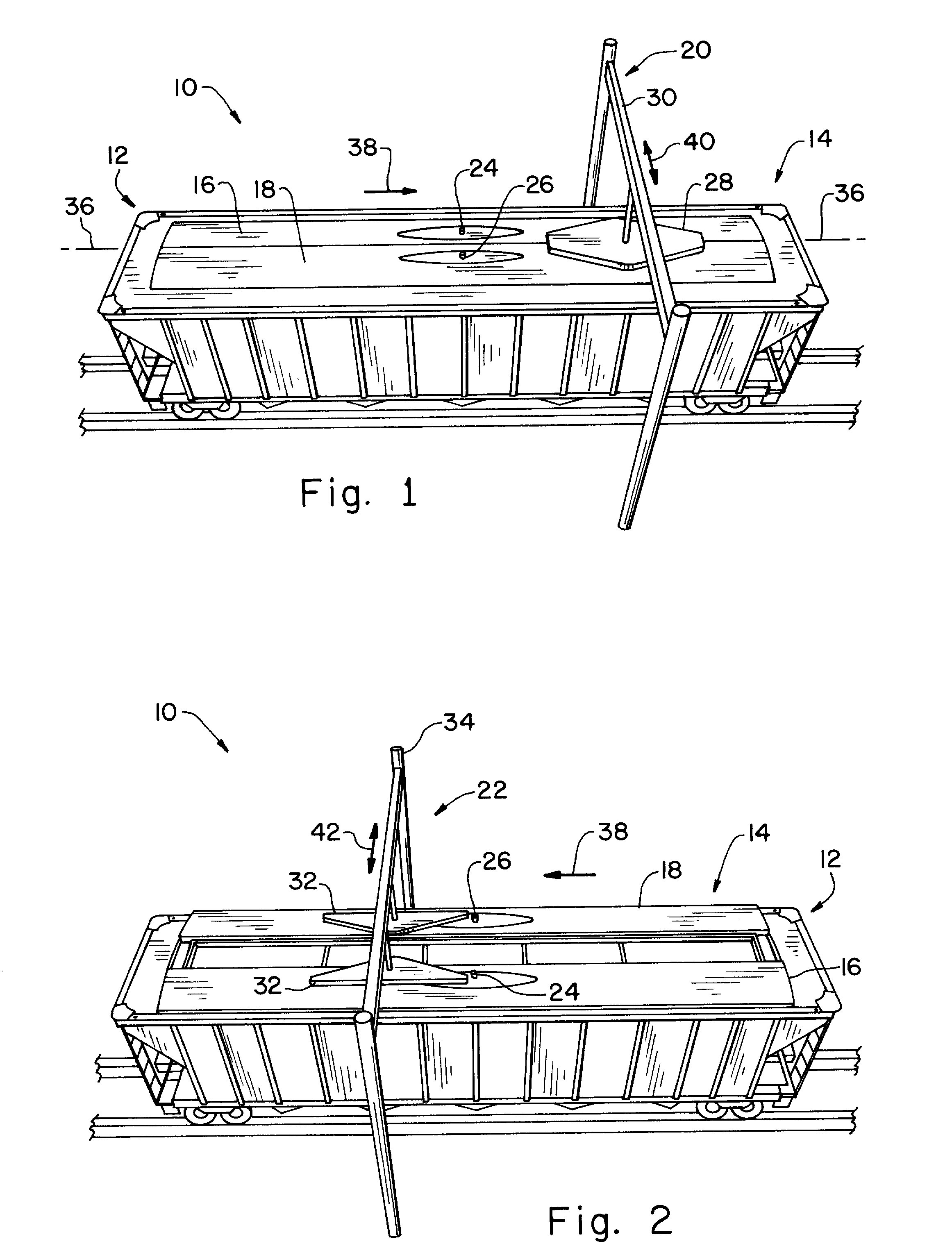

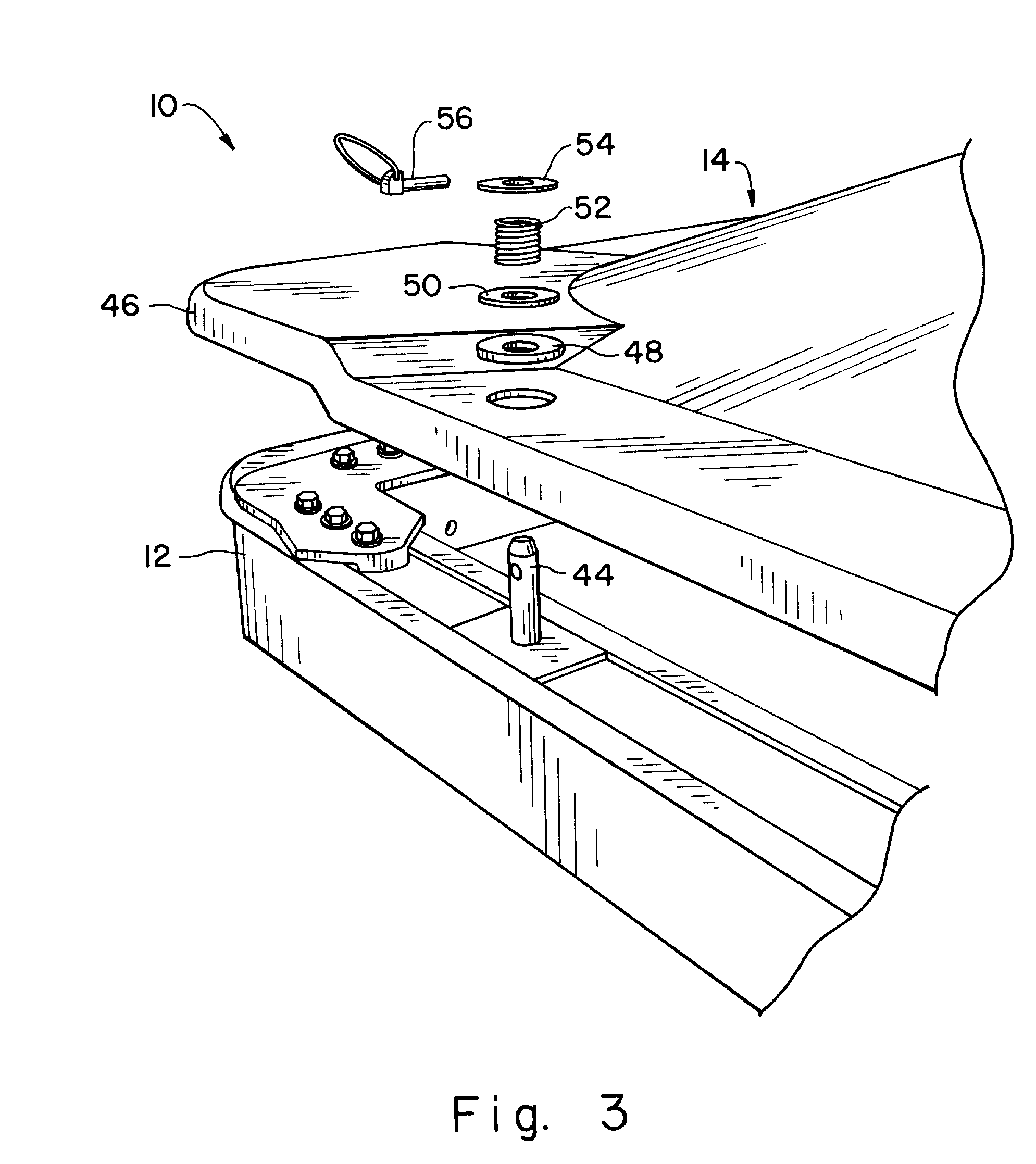

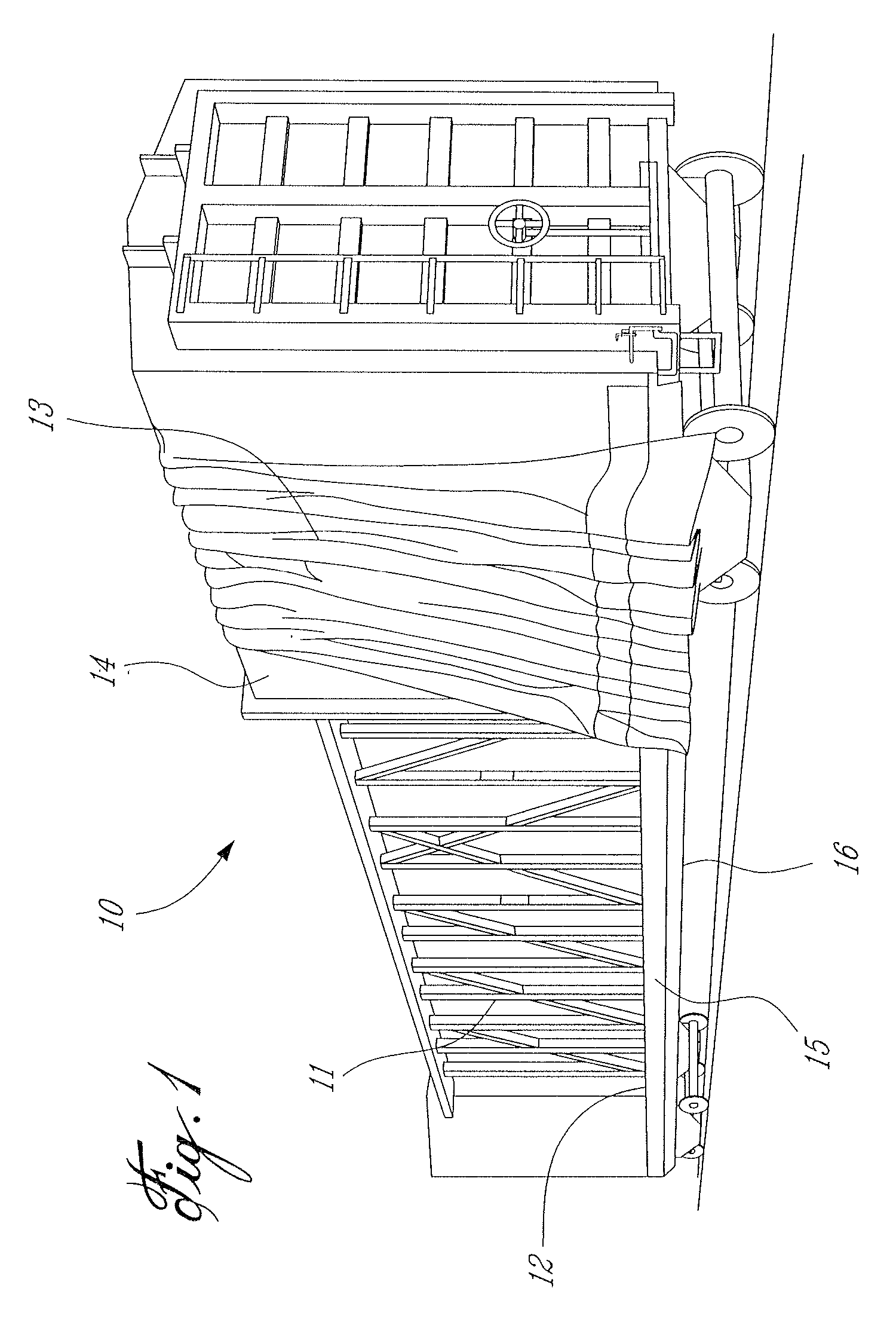

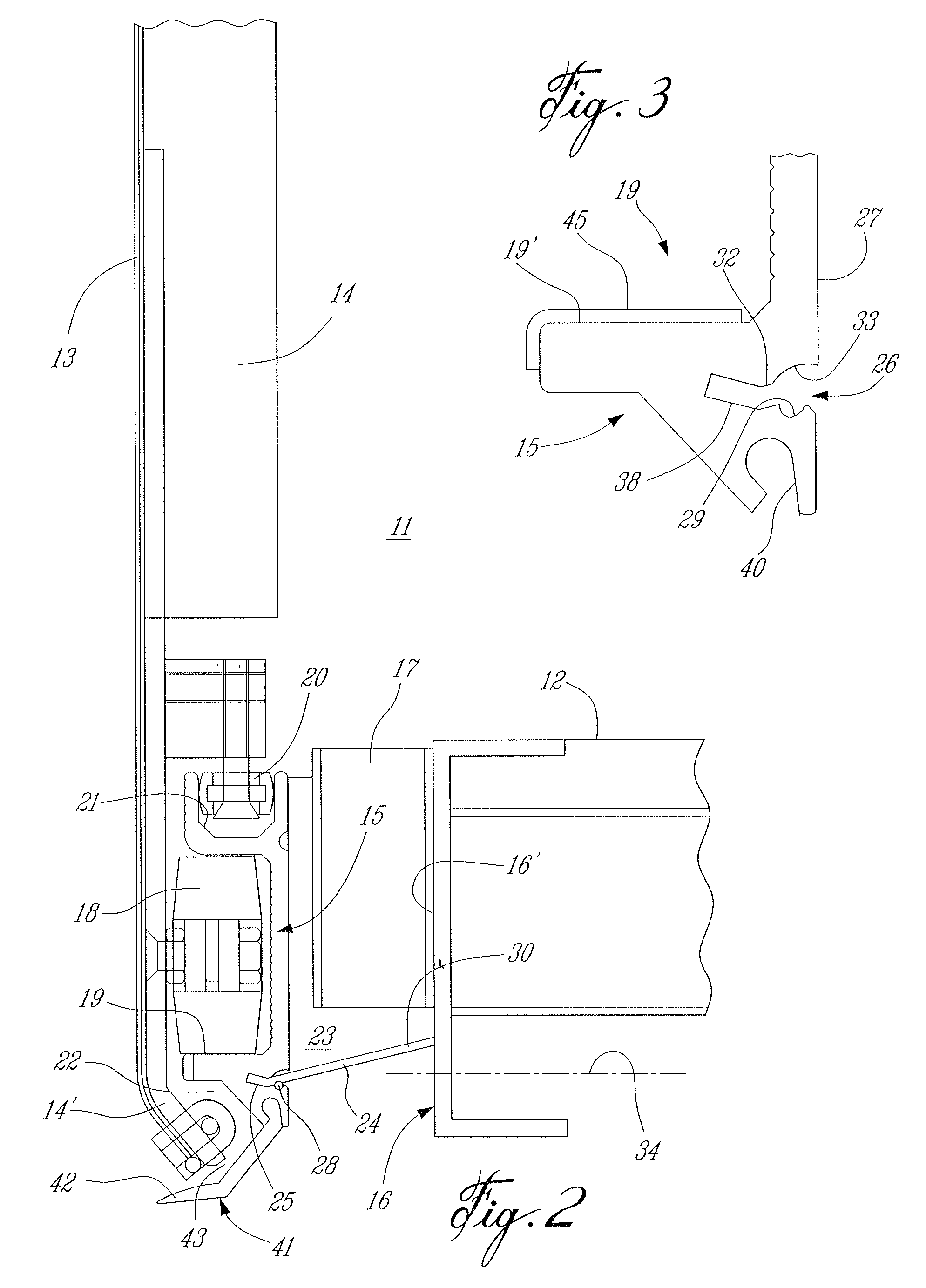

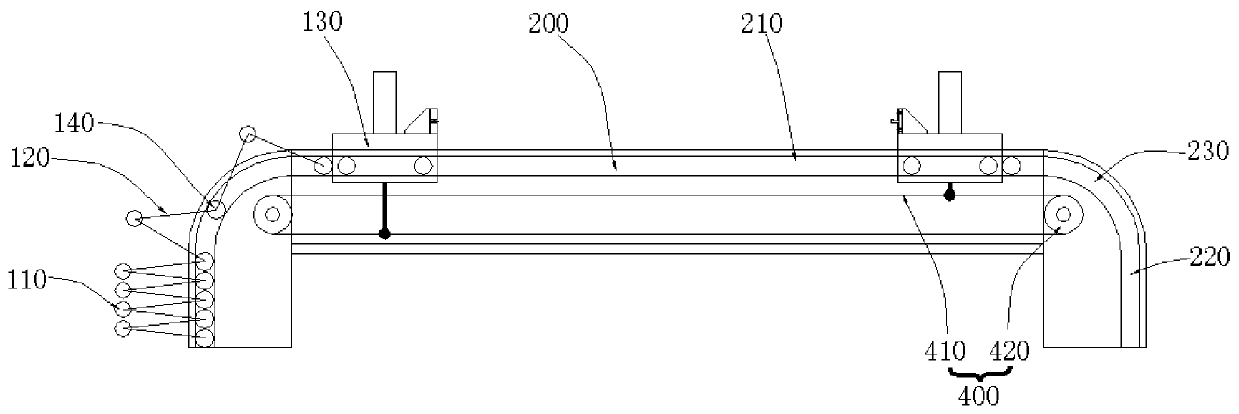

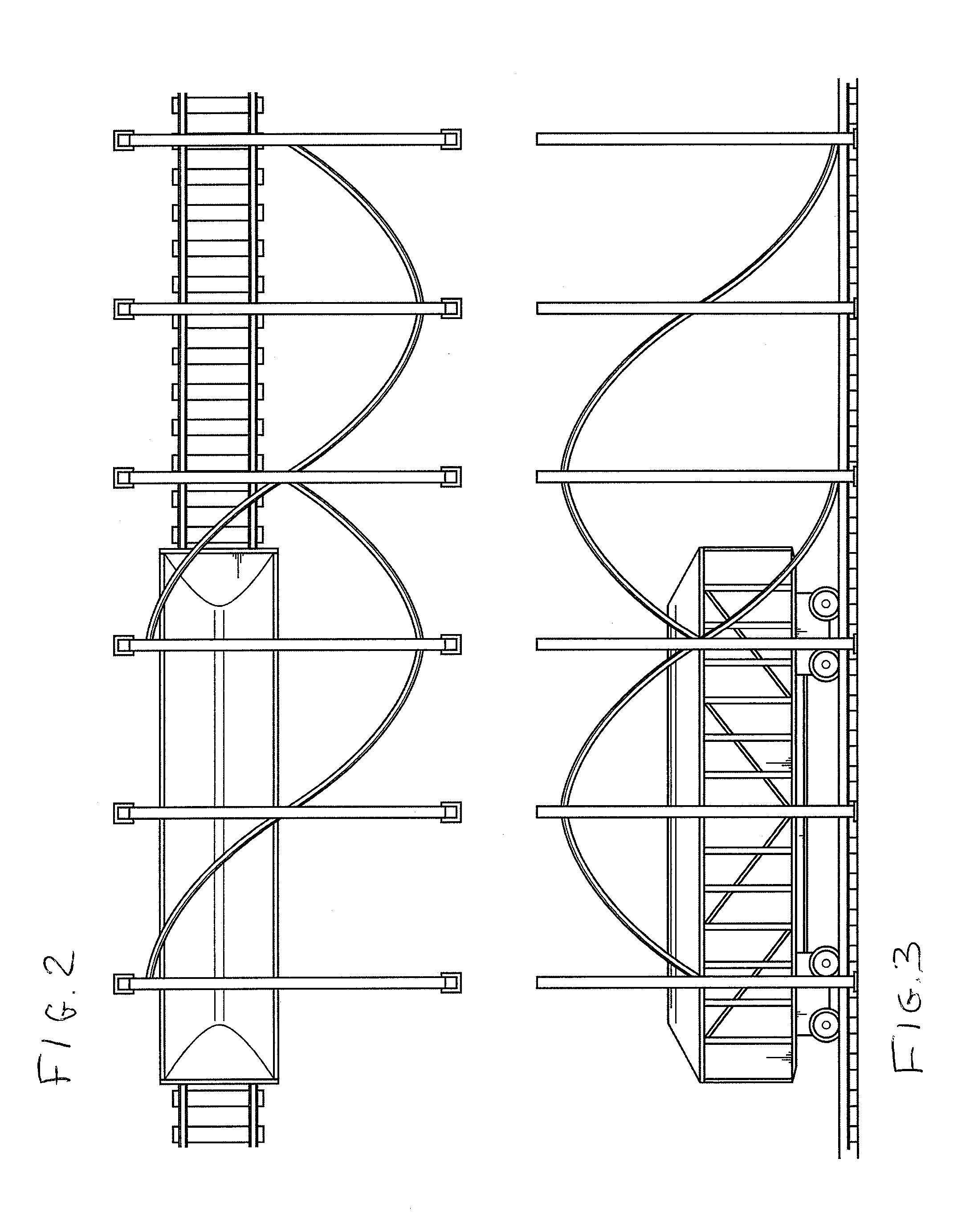

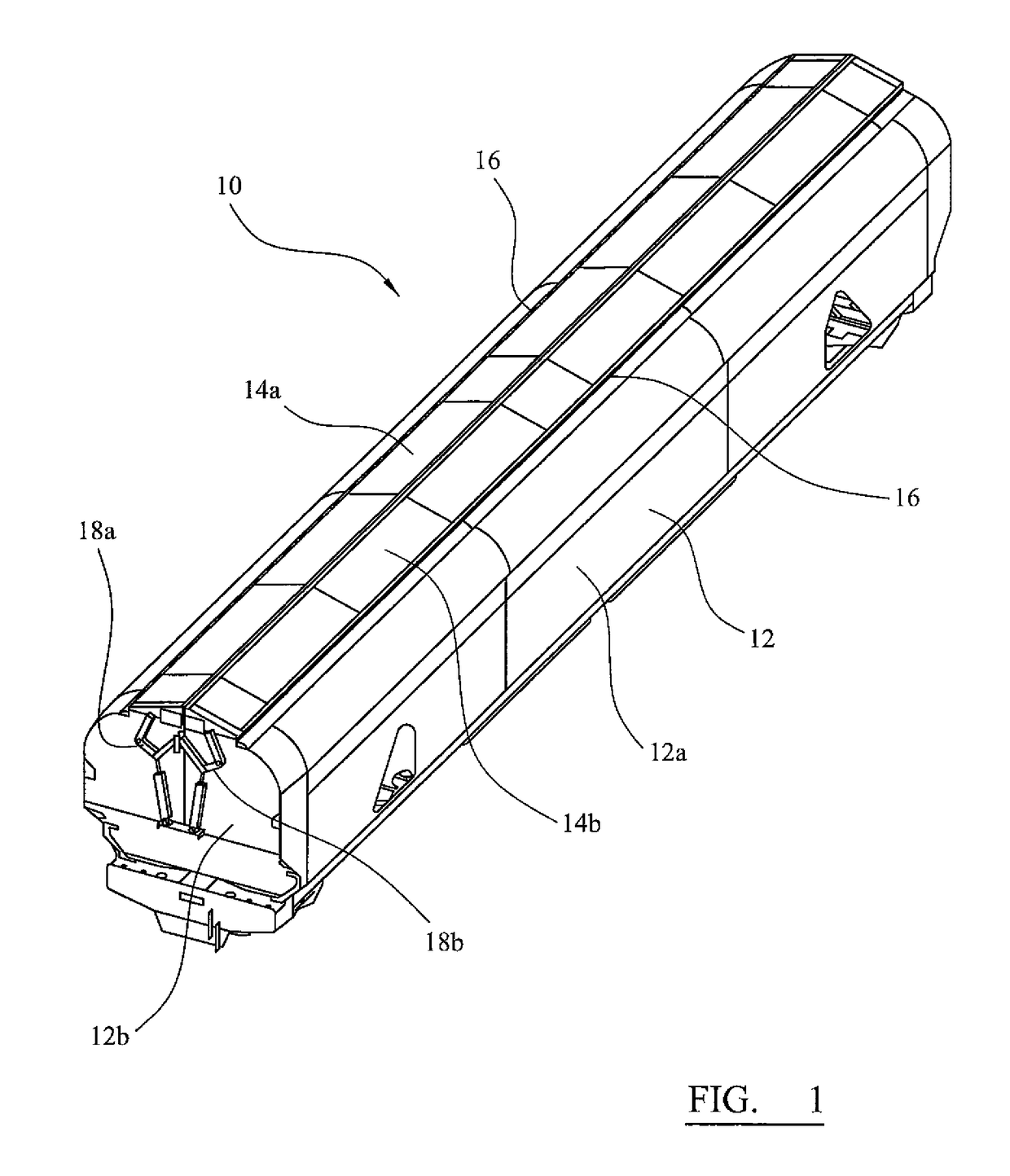

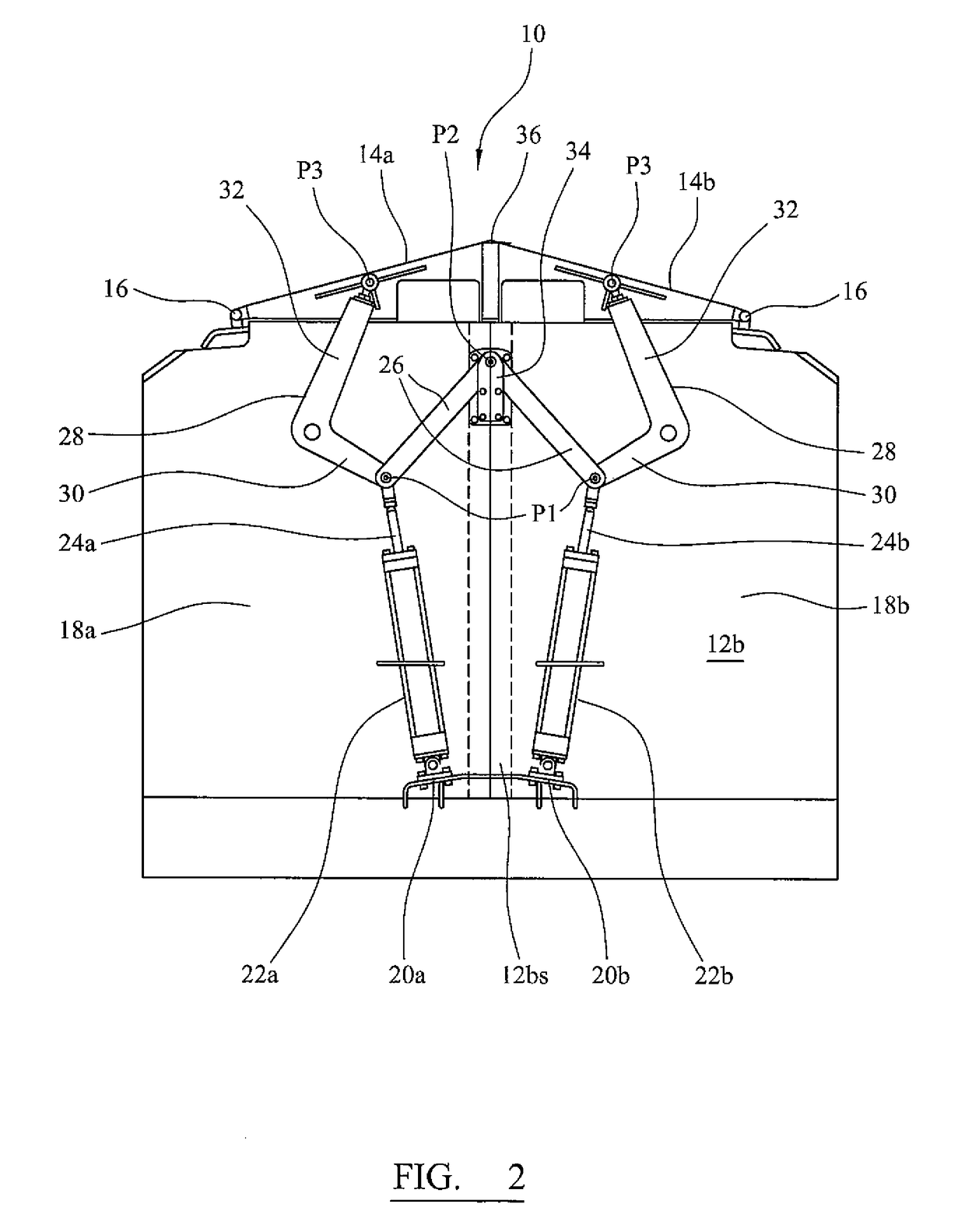

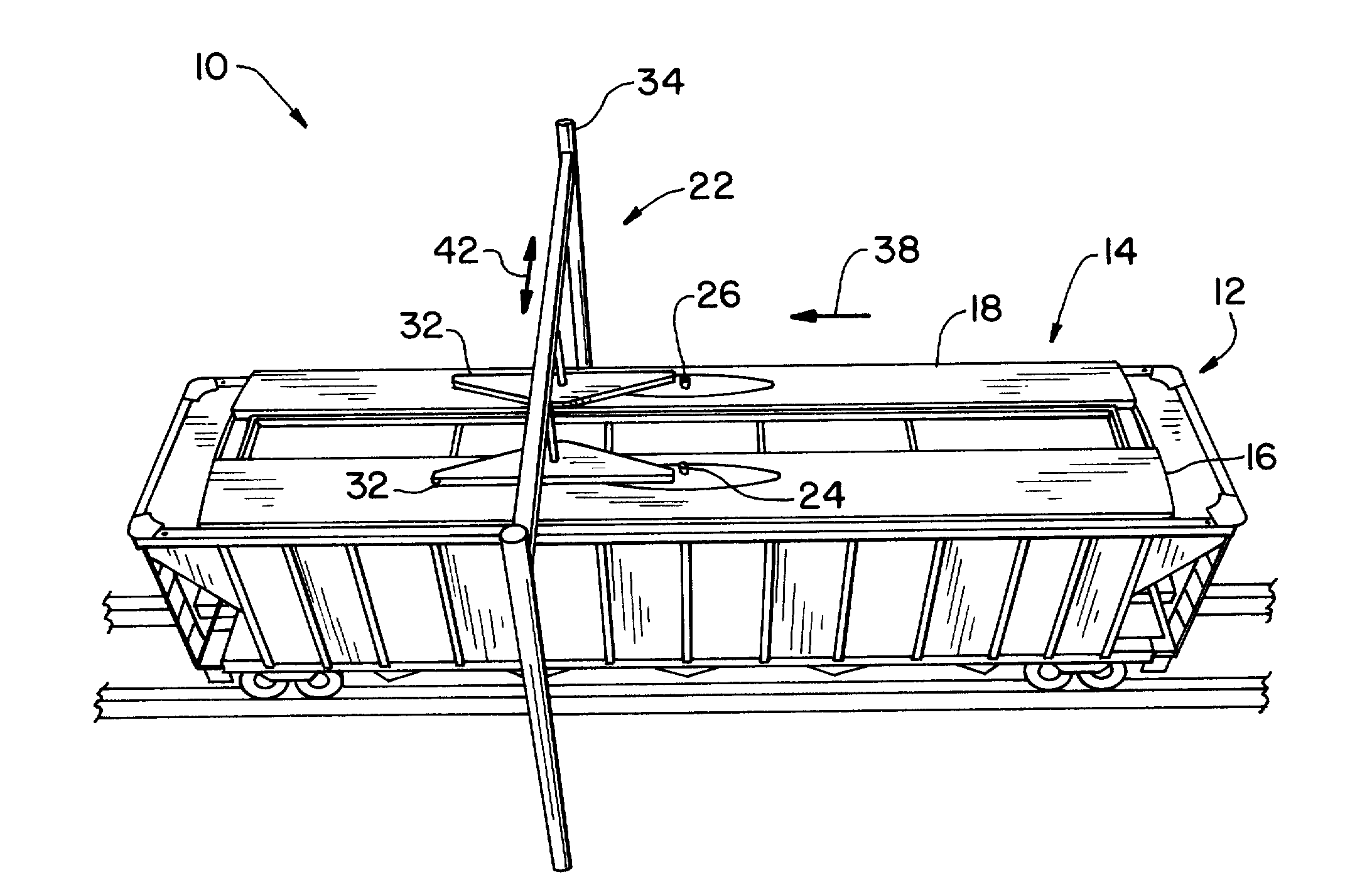

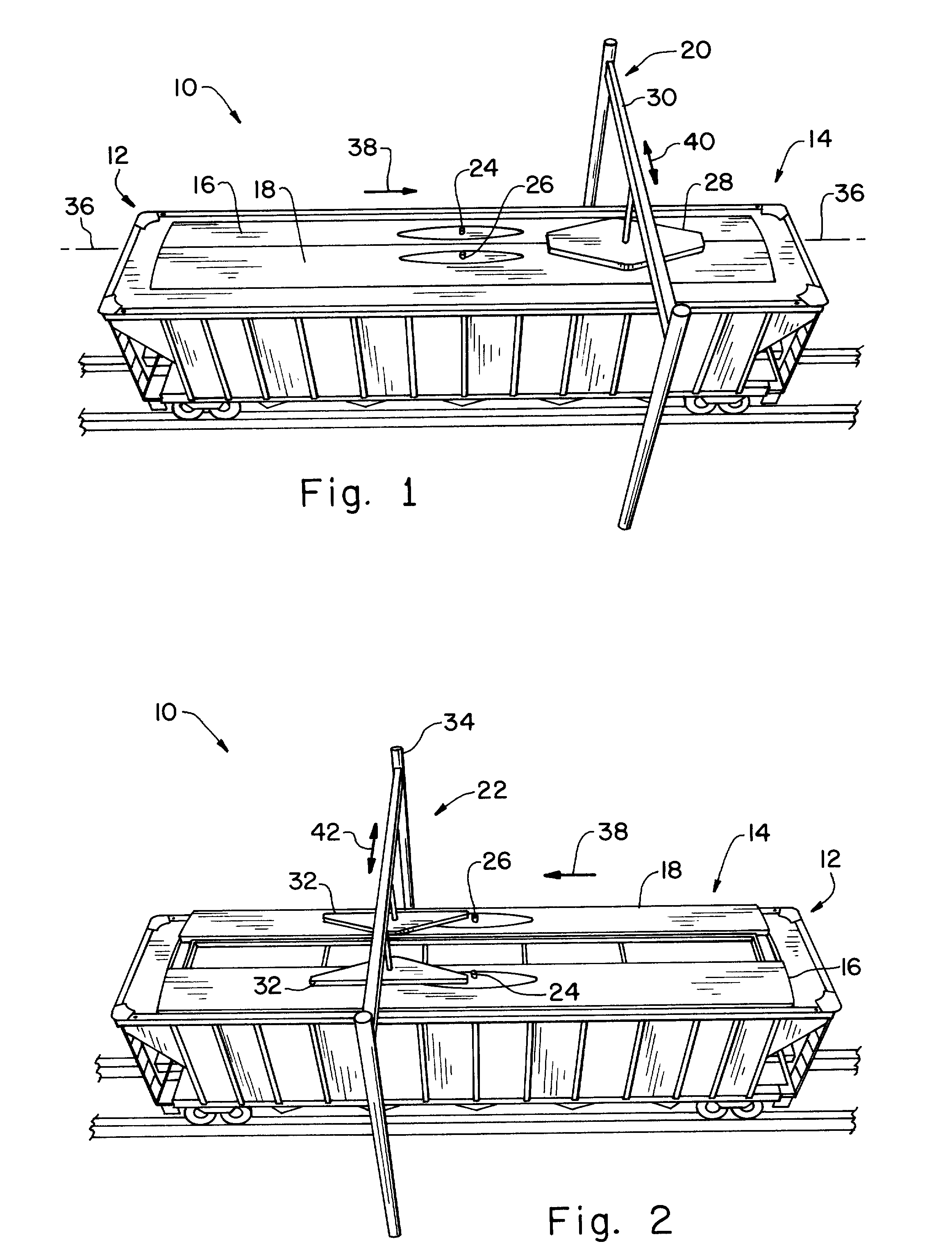

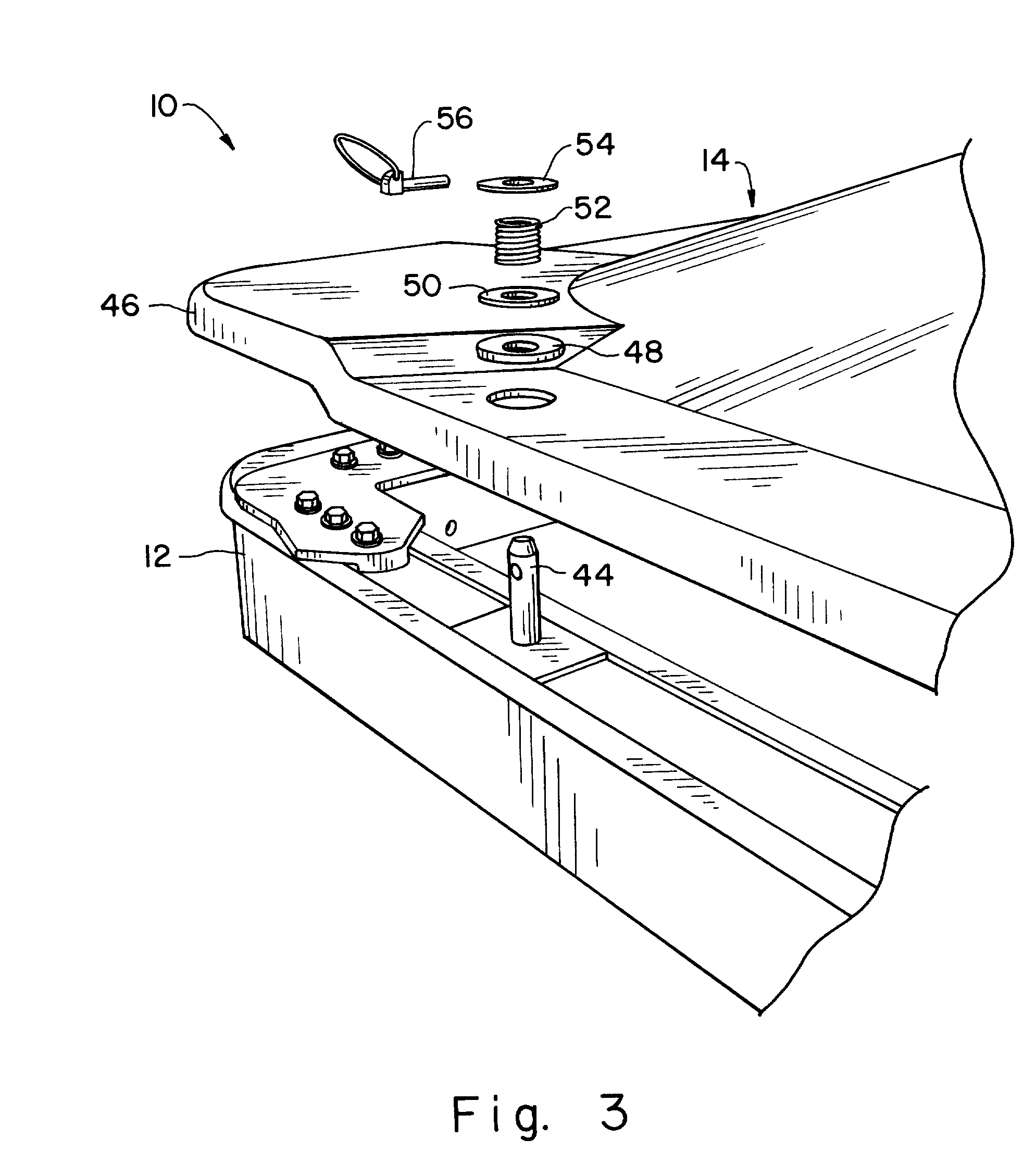

Slidable cover assembly for merchandise carrying vehicle platforms

ActiveUS6976433B1Easy to assembleMove quicklySliding roofsTransportation itemsBraced frameLocking mechanism

A slidable cover assembly for merchandise carrying vehicle platforms is described. The cover assembly comprises a pair of opposed end support frames and a plurality of intermediate frames, each having a top carriage for displacement on a central horizontal top center beam member secured to the platform. Each end support frame and intermediate frames have a top tapered roof truss structure and opposed depending side members. The side members have a side rail engaging carriage at a lower end thereof for displaceable support engagement with a side rail secured to opposed sides of the platform. A tarp is secured to the end support frames and intermediate frames and displaceable therewith from a collapsed condition to an extended condition. Tarp displacement mechanisms are provided to displace the tarp side walls outwardly of the intermediate frames when the frames are displaced closer to one another from the extended condition to the collapsed condition. The end support frames have a vertical connecting wing flange disposed vertically along at least a portion of the opposed depending side members and adapted to be detachably secured to a locking mechanism secured to stationary opposed bulk head frames of the platform.

Owner:6866336 CANADA INC

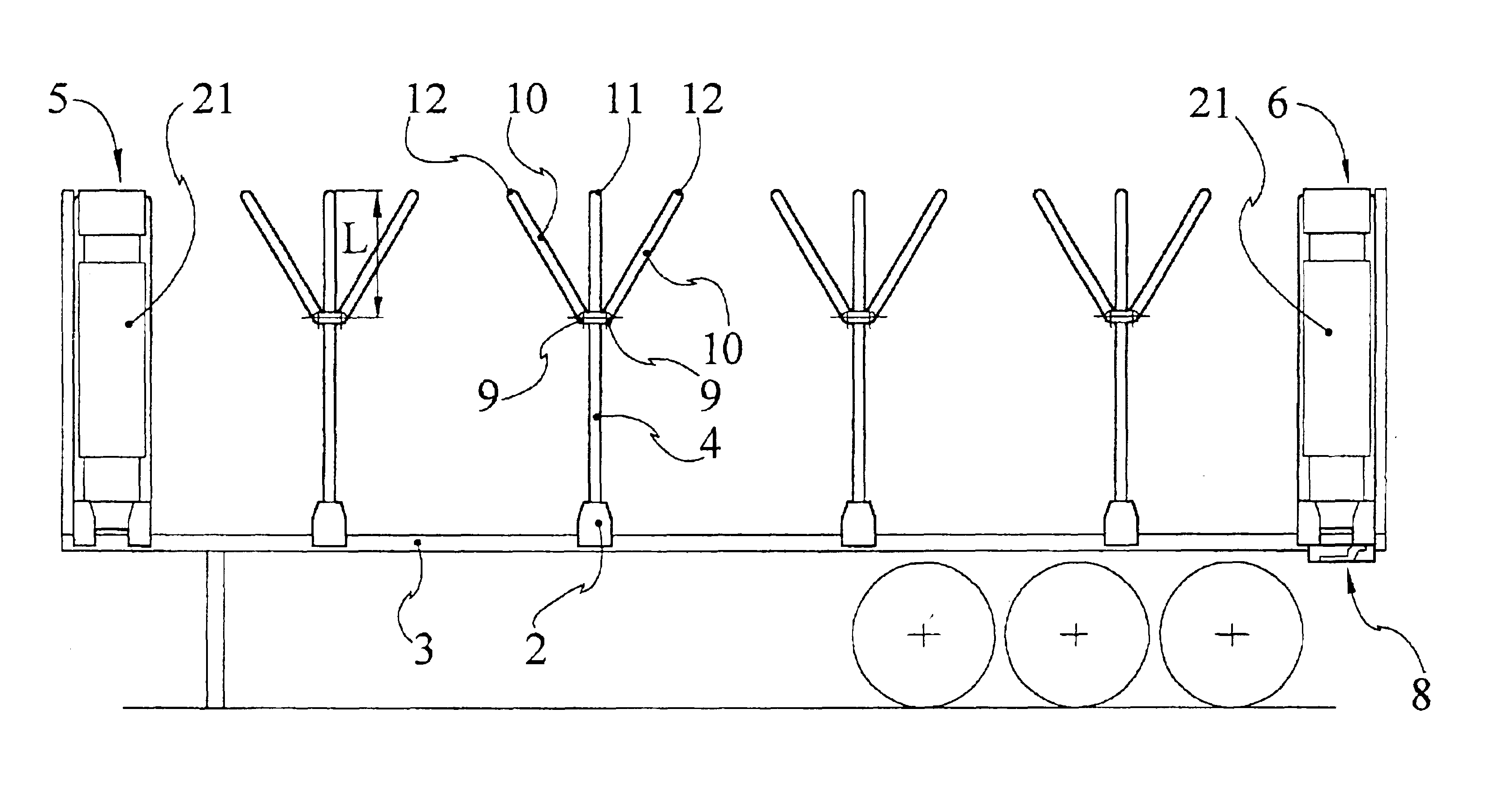

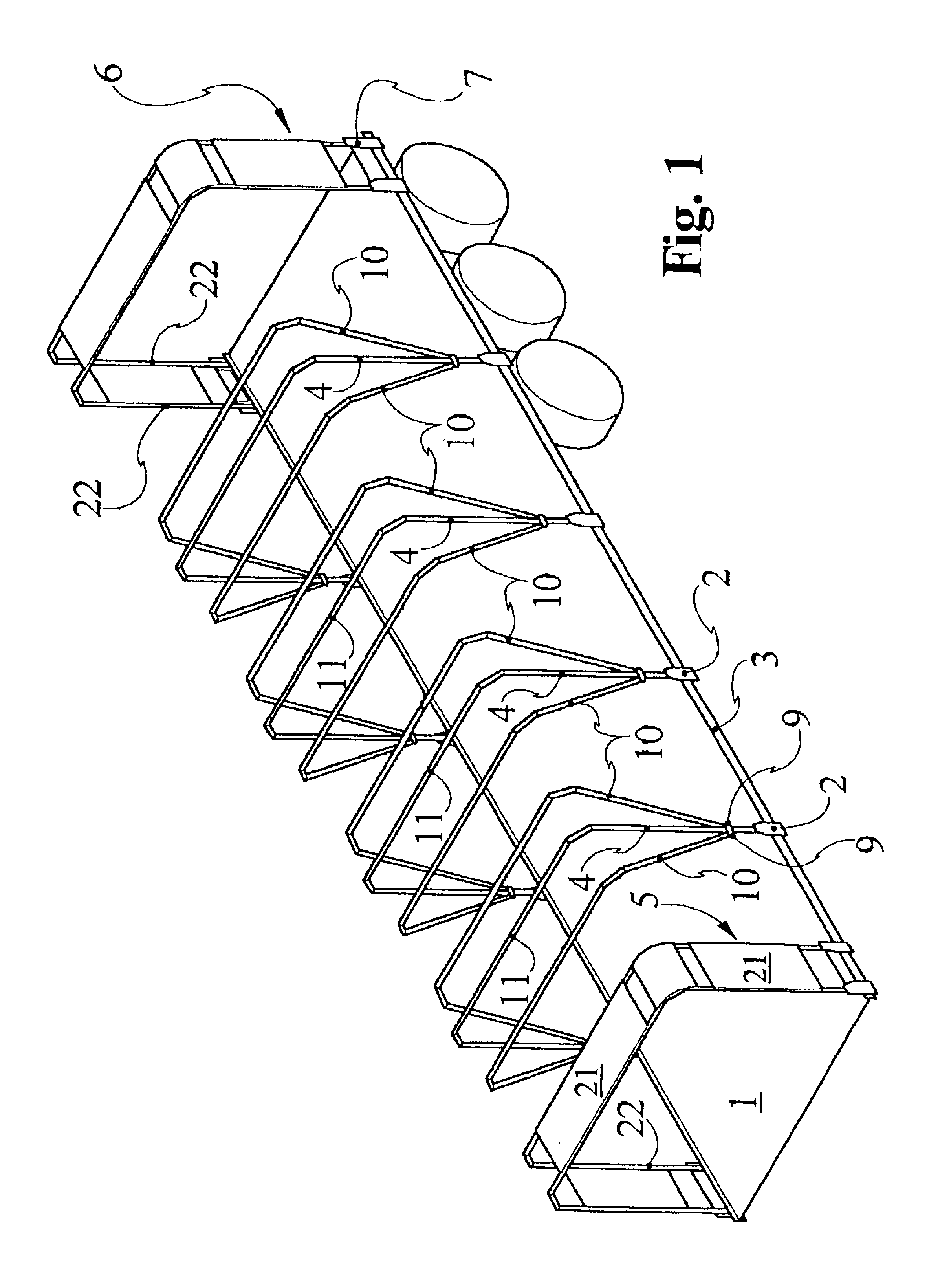

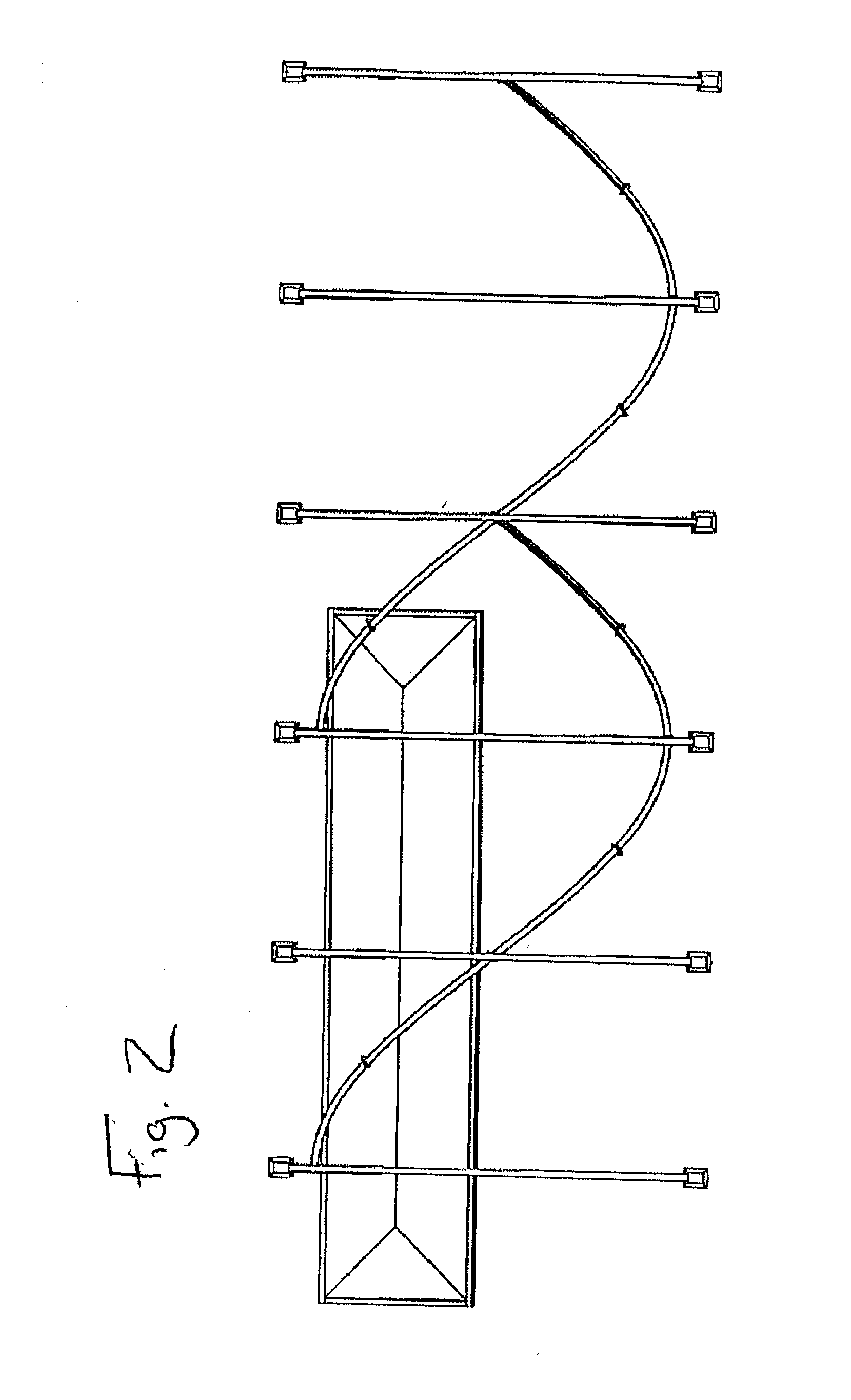

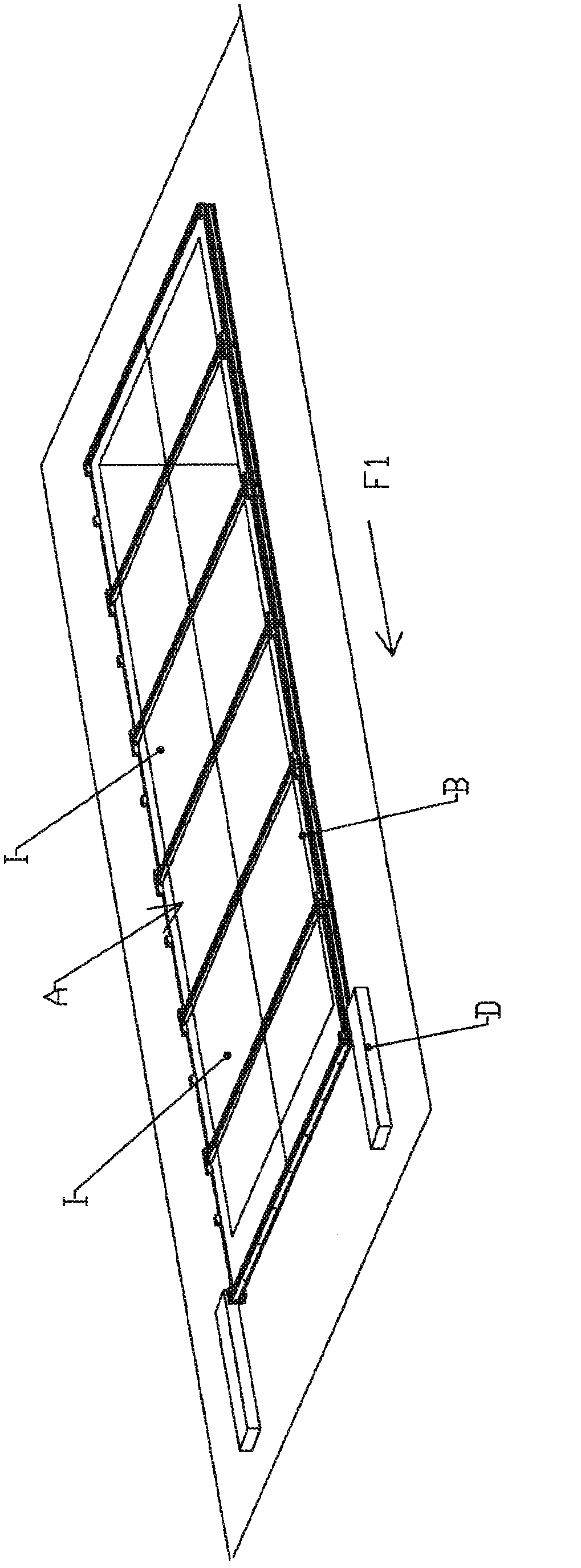

Sliding-bow folding up

InactiveUS6905161B2Resistance to foldingSufficient openingSuperstructure subunitsSliding roofsEngineeringMechanical engineering

A tarpaulin bow cover system for vehicle such as lorries or trailers includes a number of U-shaped bow members which cover the width of a loading platform of the vehicle and for opening or closing the cover by means of rollers or roller trolleys can be displaced in the longitudinal direction of the loading platform along running or guide rails positioned along the two lateral sides of the loading platform. When the cover system is closed the bow members on their bow elements, which define an upper limit, support a tarpaulin which covers the loading platform or the loading area of the vehicle. A first terminal bow member is immovably fixed to a face end of the loading platform and a second mobile terminal bow member is assigned to at least one fixing or locking device which is positioned at the other end of the loading platform. At least one U-shaped auxiliary bow member, which can be pivoted in a limited angular area about an axis of articulation parallel to the plane of the bow member, is arranged at the level of the bow member and the length of the legs of the auxiliary bow member is greater than the distance between the axis of articulation and the bow element of the corresponding bow member.

Owner:EDSCHA LKW SCHIEBEVERDECKE

Exposure apparatus and method

InactiveUS7180574B2Efficient removalInhibit deteriorationRailway vehiclesSemiconductor/solid-state device manufacturingReticlePhysics

An exposure apparatus includes a projection optical system for projecting an image of a pattern of a reticle onto an object, via a fluid that is filled in a space between said projection optical system and the object, a vibrator part for vibrating at least one of the fluid, the object, and the projection optical system, and a controller for controlling the vibrator part so that the vibration of at least one of the fluid, the object, and the projection optical system becomes a tolerance during a processing of the object.

Owner:CANON KK

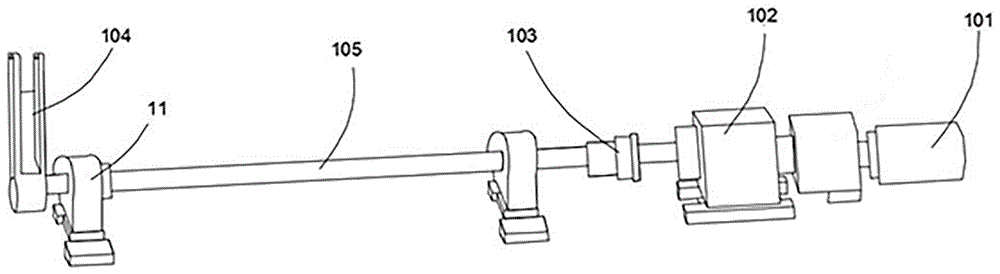

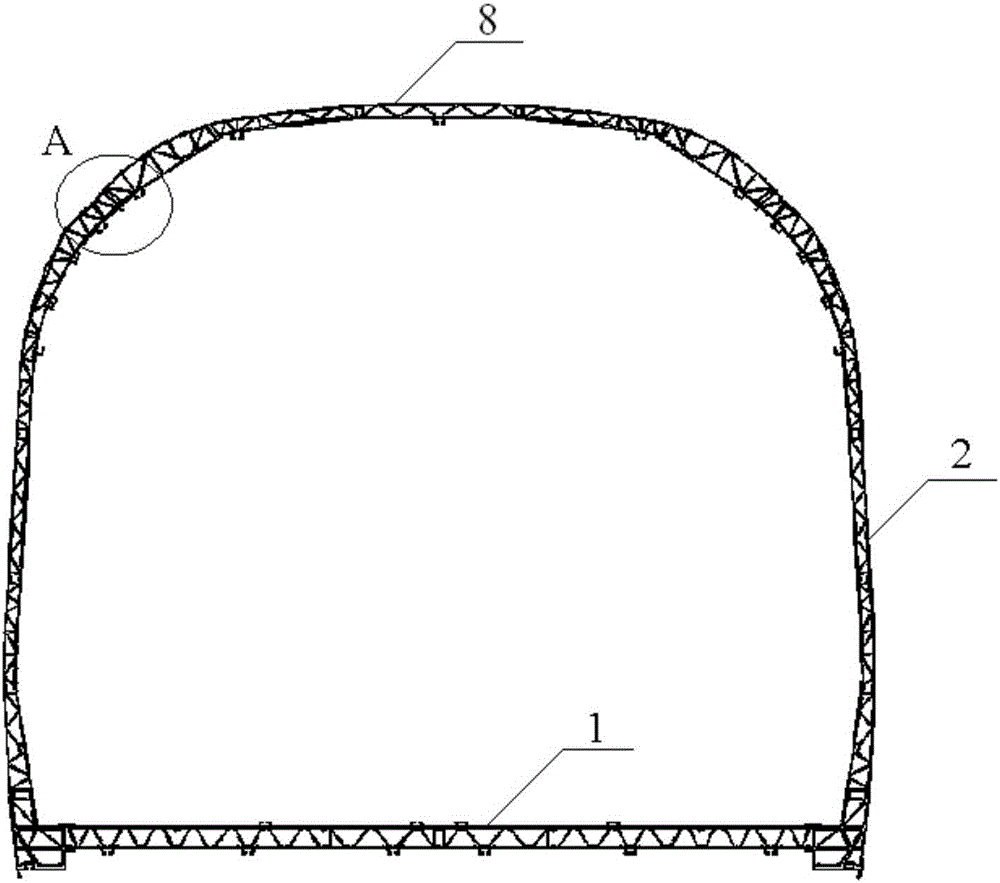

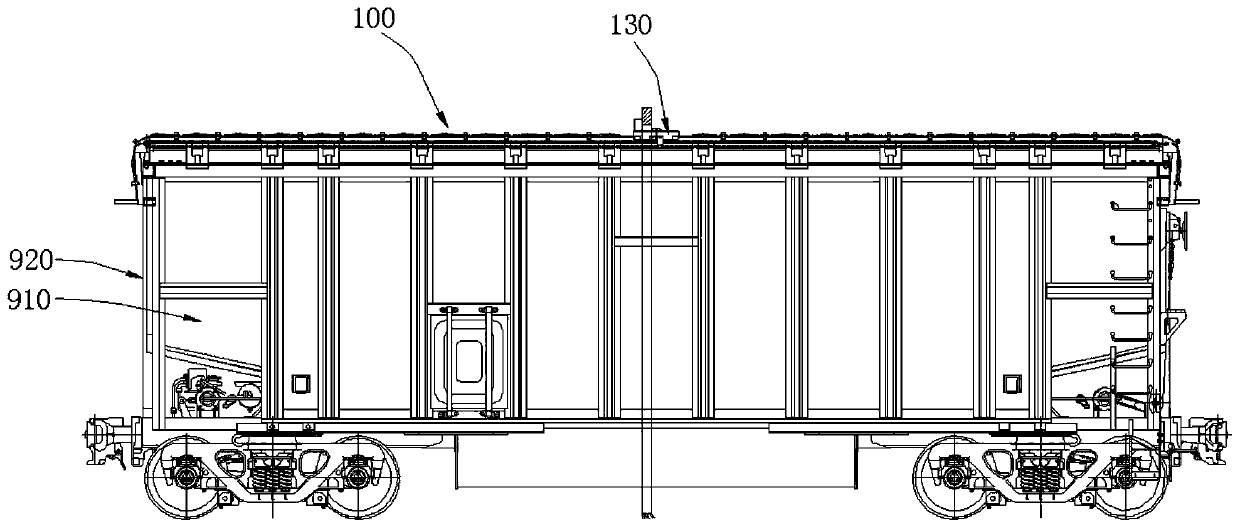

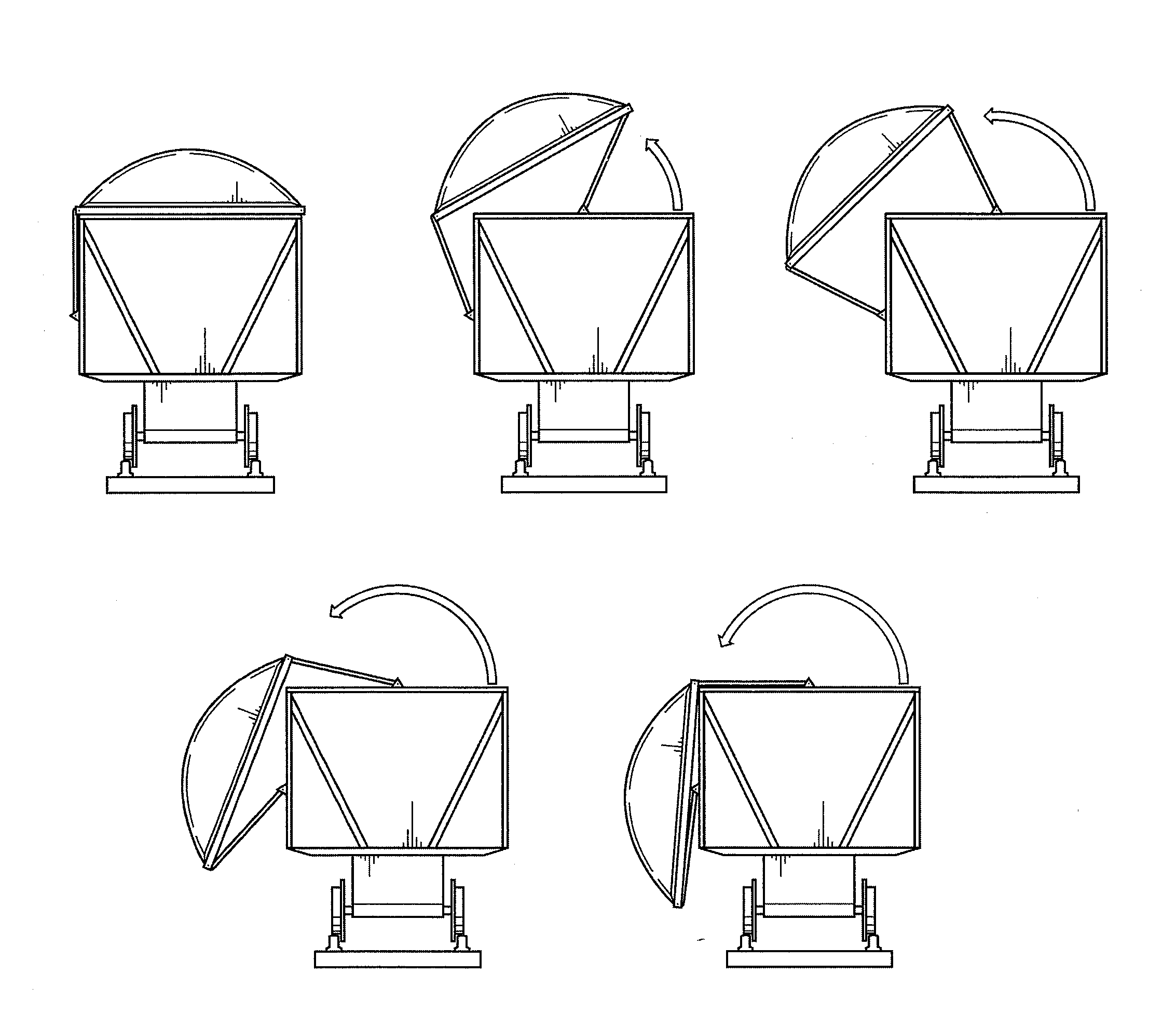

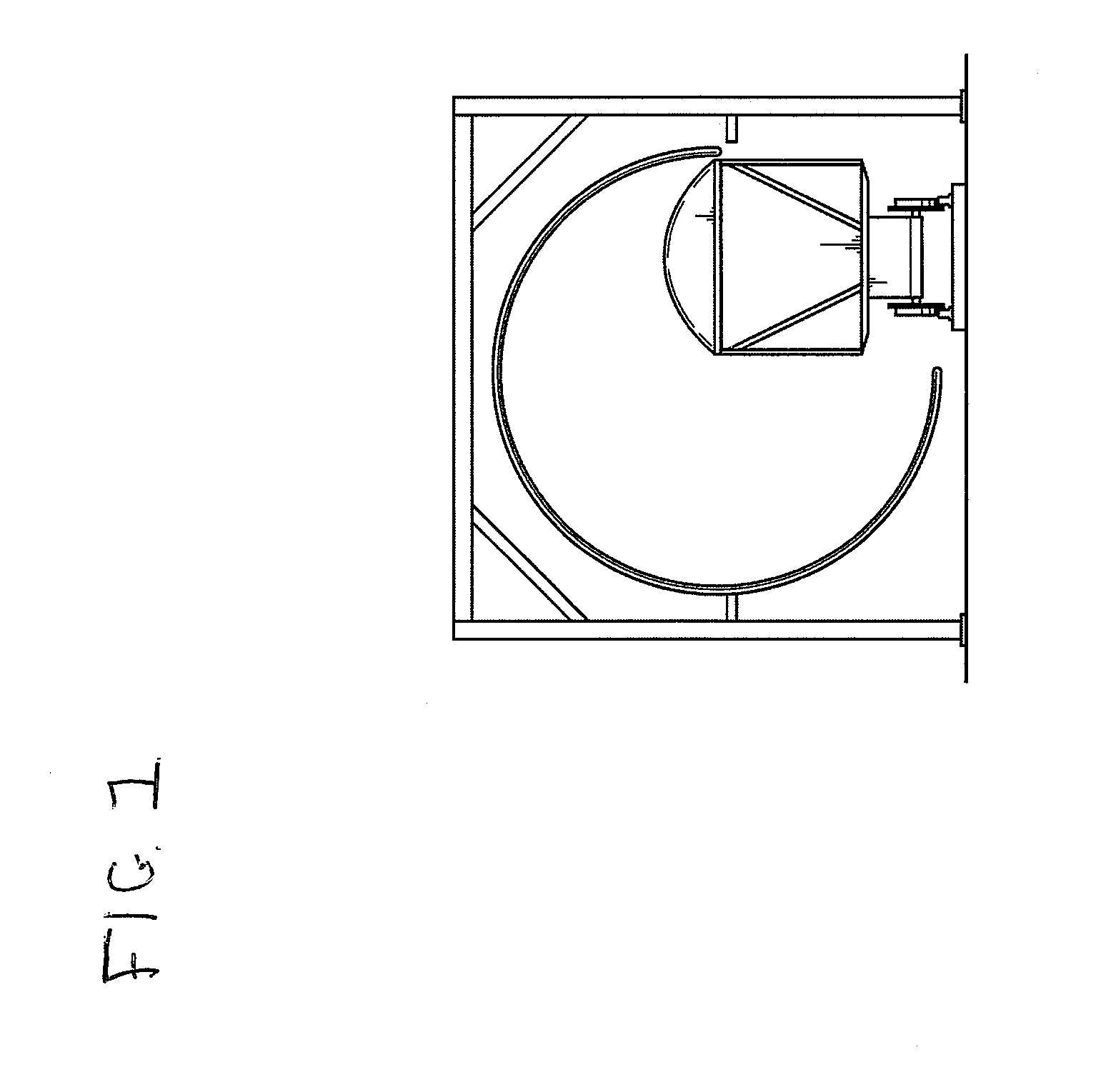

Inlet closure system

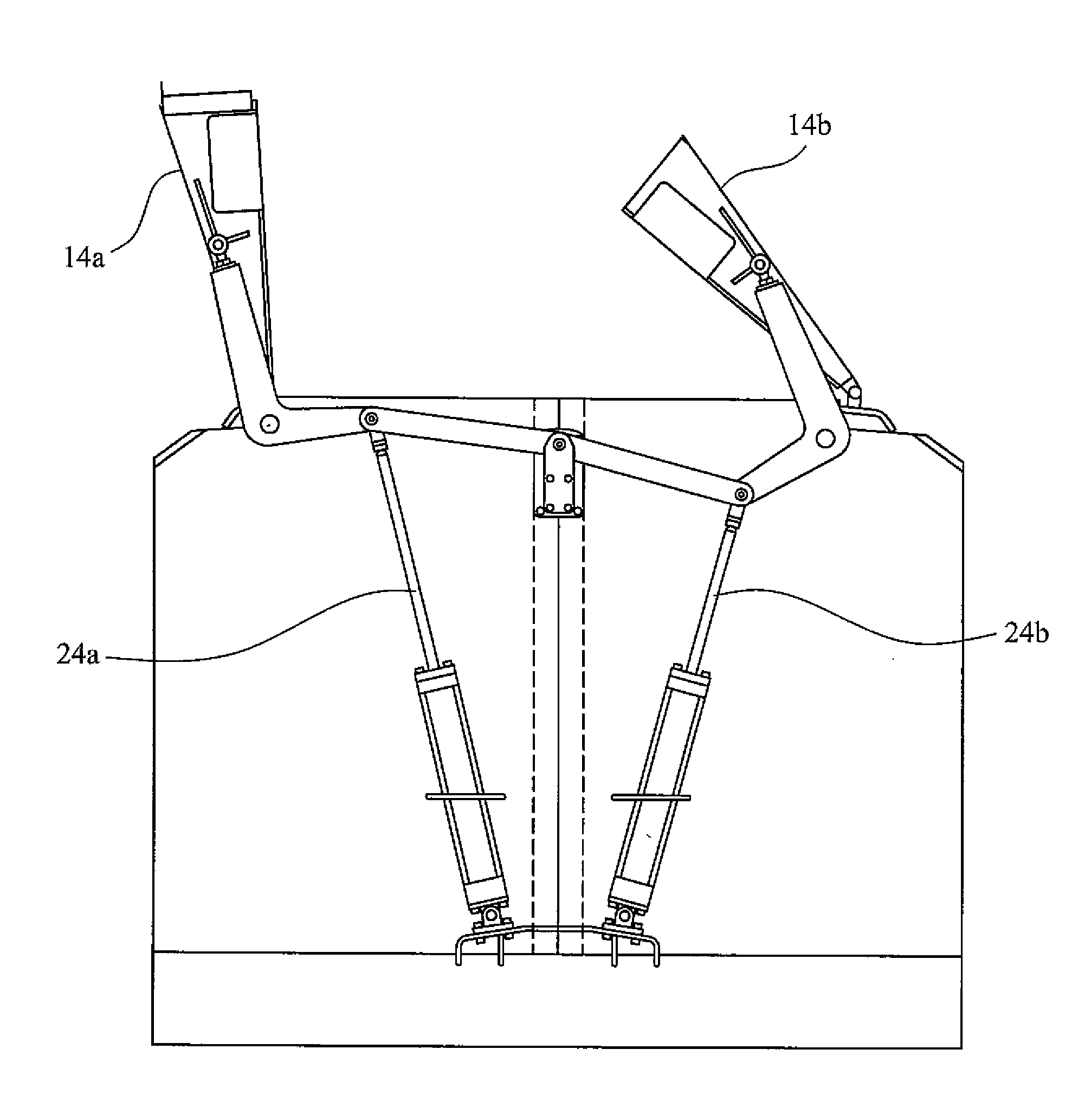

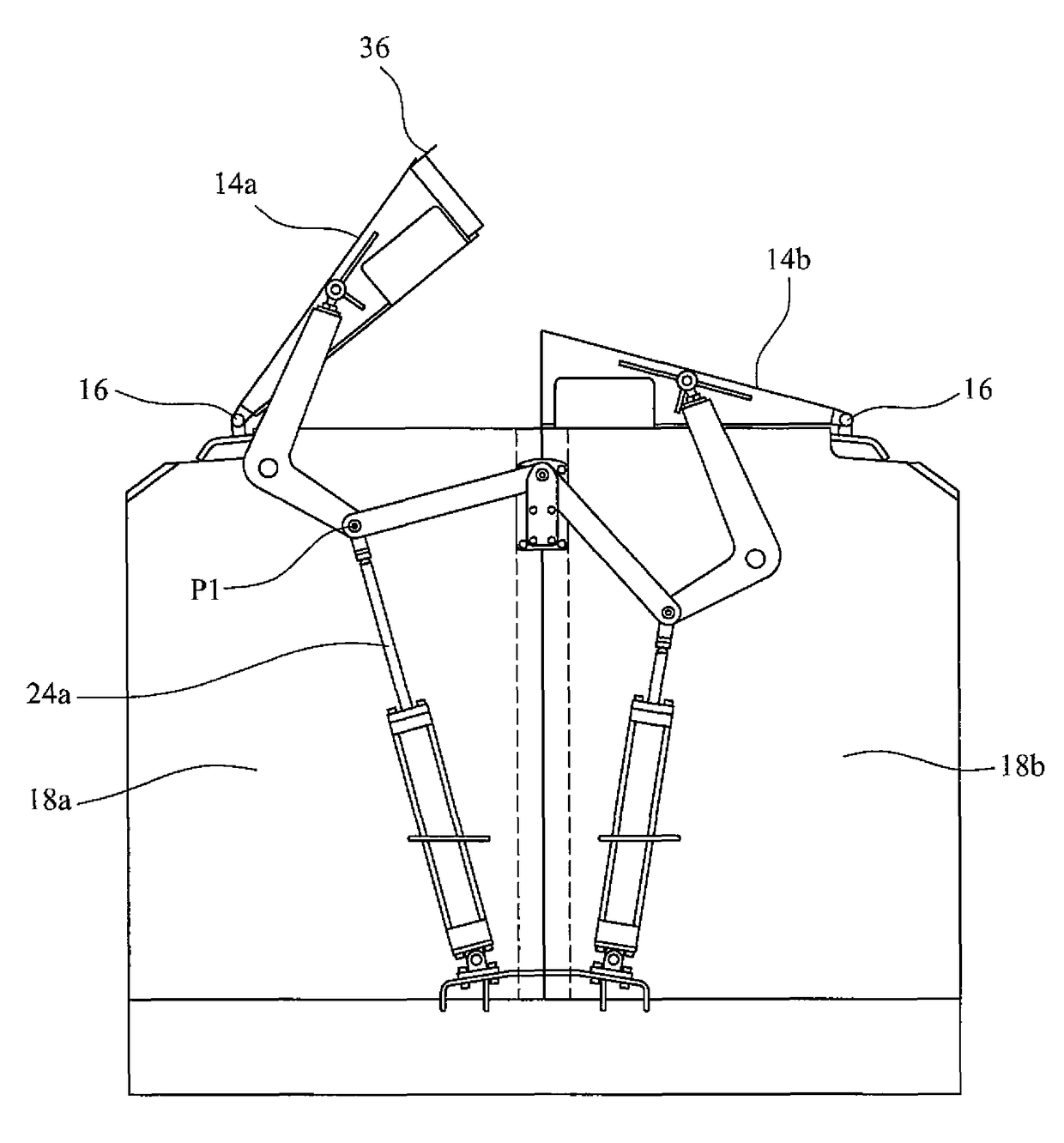

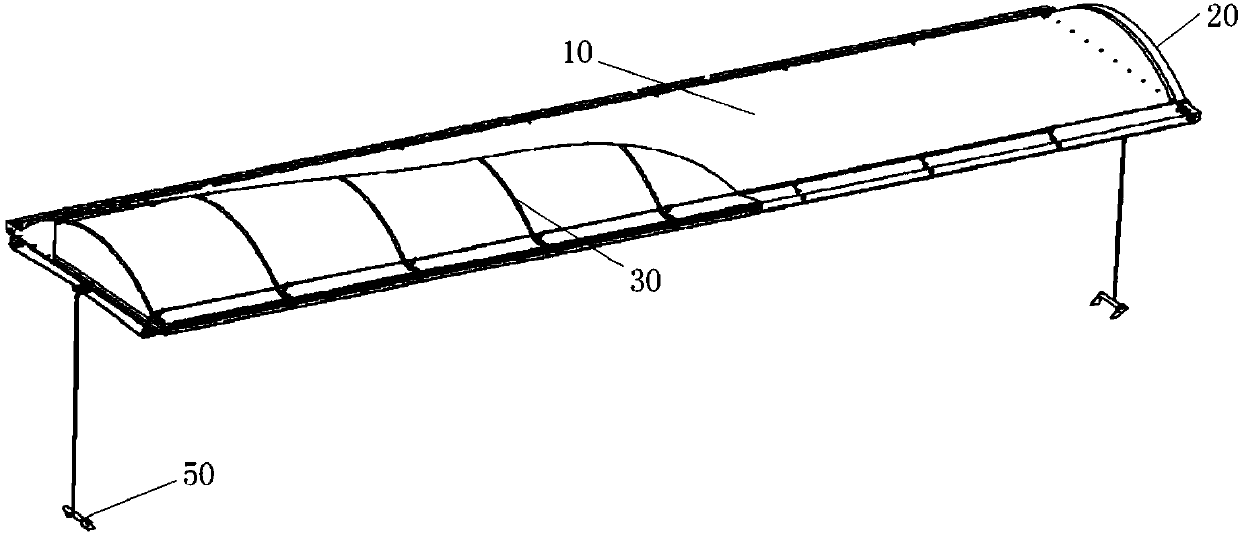

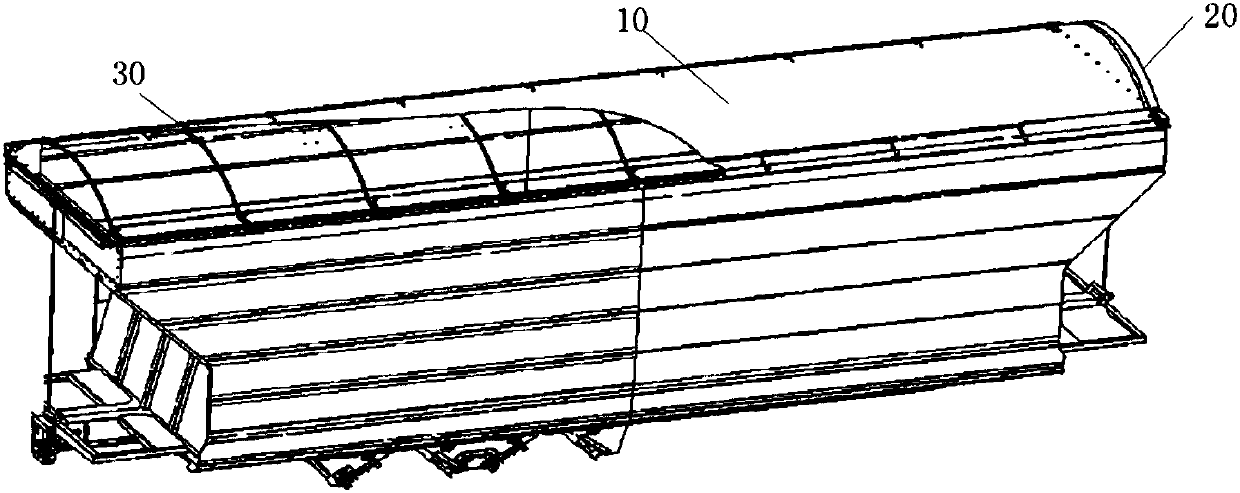

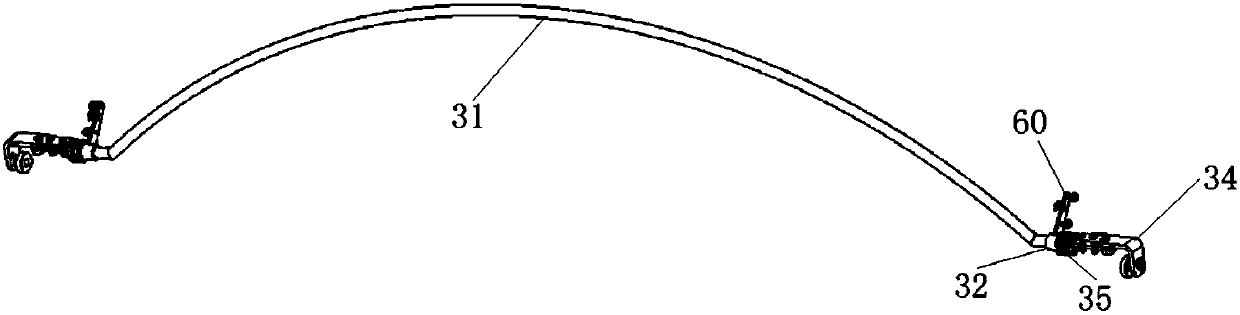

ActiveUS20160001792A1Improve structural strengthSufficient massTiltable roofsTank wagonsEngineeringActuator

The invention relates to an inlet closure system for covering an inlet formed in an upper region of a container body The container body may a storage region of a hopper, a hopper vehicle such as a hopper railway wagon or other storage devices. The inlet closure system comprises at least one closure member arranged substantially above the inlet and moveable between a first closed configuration in which the inlet is substantially closed and a second fully open configuration in which the inlet is substantially open, and at least one actuator mounted on an end wall of the container body for moving the closure member. The actuator remains below an upper edge of the end wall when the closure member is in the second fully open configuration. The actuator is arranged in use to act upon the at least one closure member via a linkage, which linkage is arranged for pivotal motion relative to the end wall about a point substantially midway between the side walls. The linkage may comprise a first link and a second link. The second link may have a first and a second limb which meet at a non-straight angle. Preferably, the first limb and / or the second link lie below the upper edge of the end wall when the closure member is in the second fully open configuration. The second limb may lie substantially beyond an inward facing surface of the closure member when the closure member is in the second fully open configuration. If two actuators are arranged to act upon respective closure members, the first links of the linkages are arranged to pivot about a common pivot point. The common pivot point is preferably located on the end wall at a point substantially midway between the sidewalls.

Owner:DRAX POWER

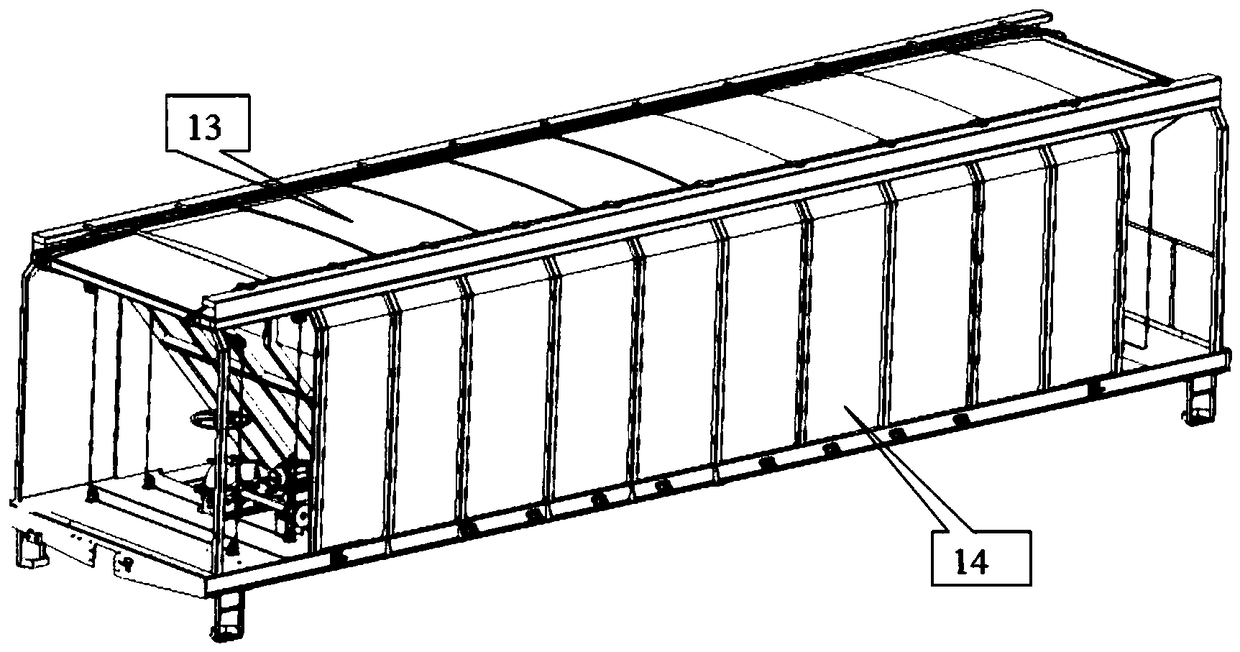

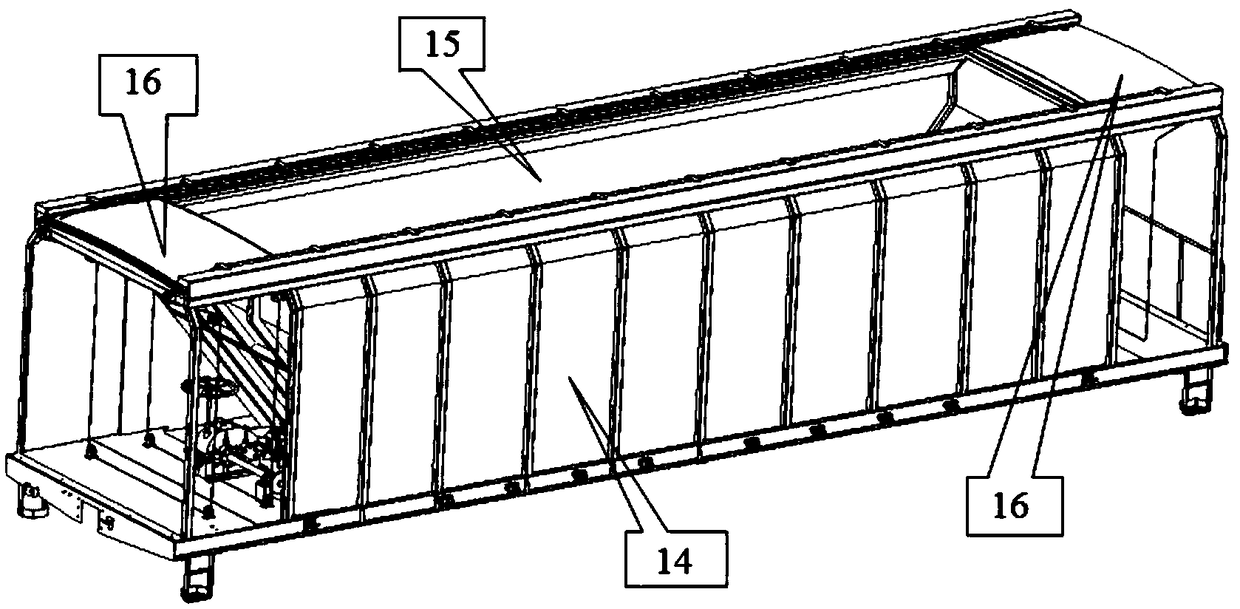

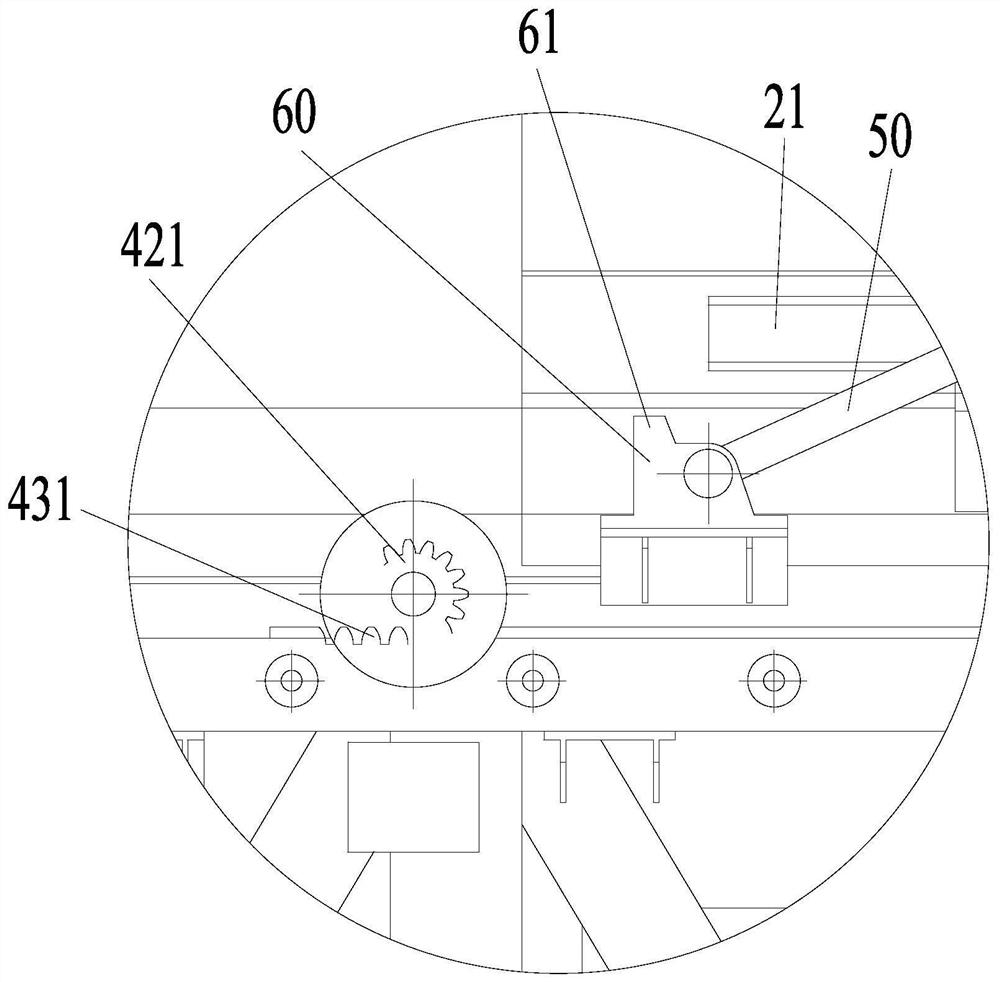

Sliding top cover of railway maneuvering equipment vehicle

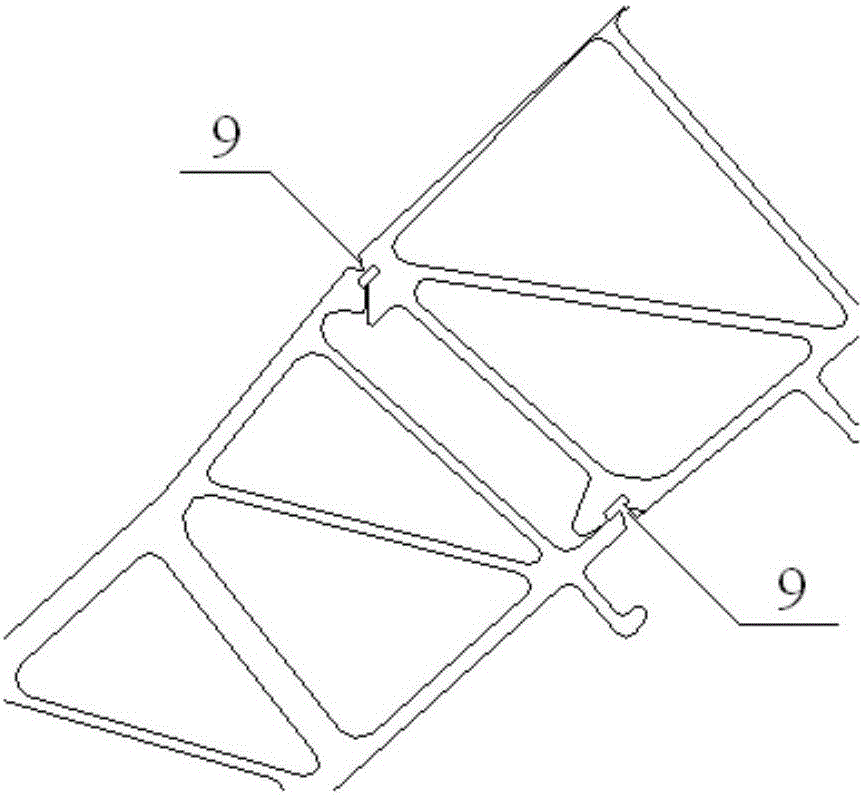

PendingCN111520022AReduce complexityNo offsetWing fastenersPower-operated mechanismGear wheelMachine

Owner:CRRC YANGTZE CO LTD

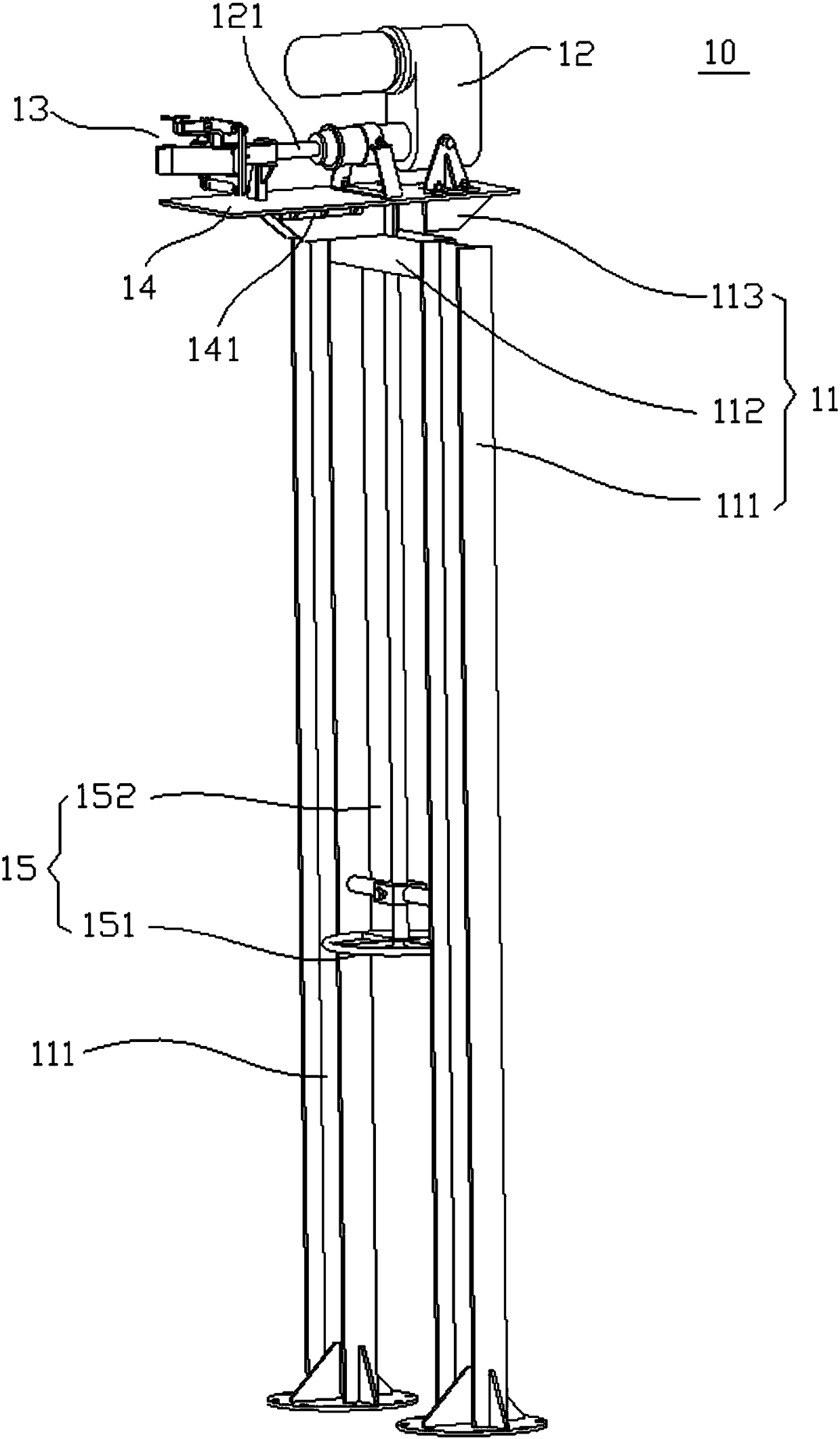

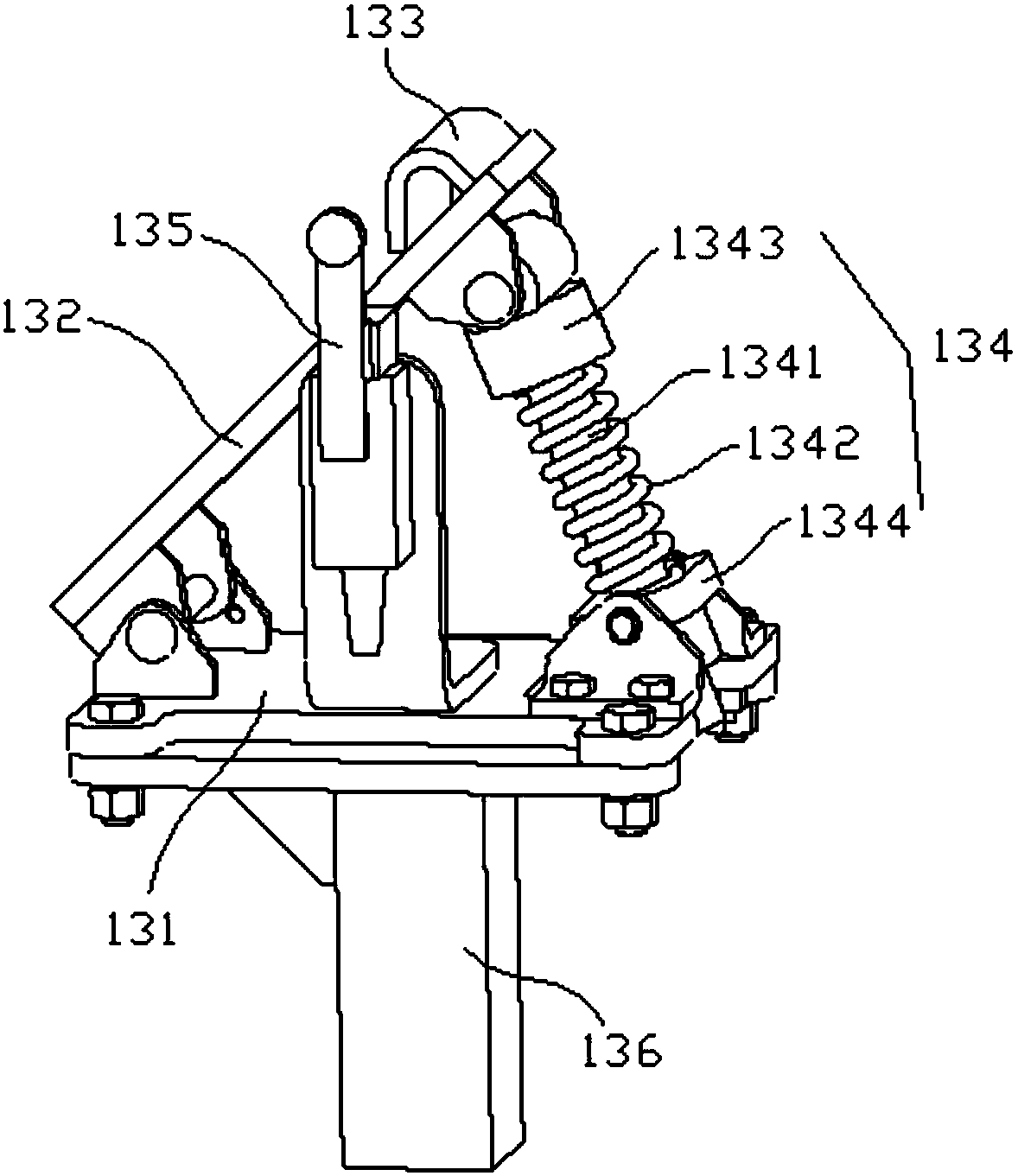

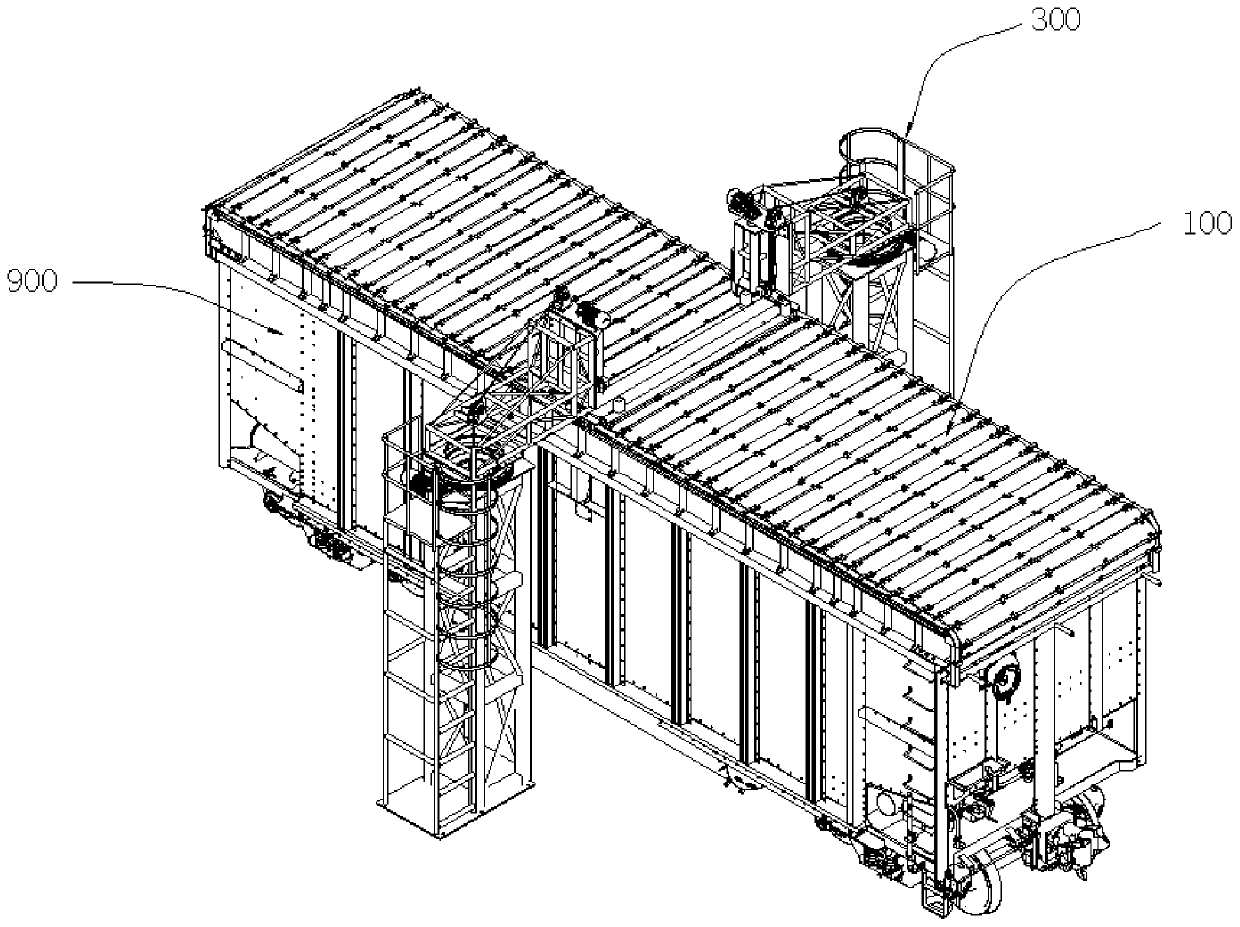

Rail wagon top cover open-close system and ground head meeting device thereof

The invention discloses a rail wagon top cover open-close system and a ground head meeting device thereof. The ground head meeting device comprises a bracket assembly, a first driving part and a headmeeting assembly. The first driving part is mounted on the bracket assembly and is provided with a telescopic end, and the telescopic direction of the telescopic end is perpendicular to the vertical direction and is capable of expanding and contracting in the lateral direction of a vehicle. The head meeting assembly is mounted at the telescopic end of the first driving part. According to the ground head meeting device, installation of complicated drive mechanisms on each compartment of a rail wagon can be avoided, the weight of a vehicle body and cost can be greatly reduced, and the transportation economy is improved; and meanwhile, only the relevant dimensions of the installation of the ground head meeting device need to be adjusted for different vehicle types, the application range is wide, and the adaptability is strong.

Owner:CRRC QIQIHAR ROLLING CO LTD

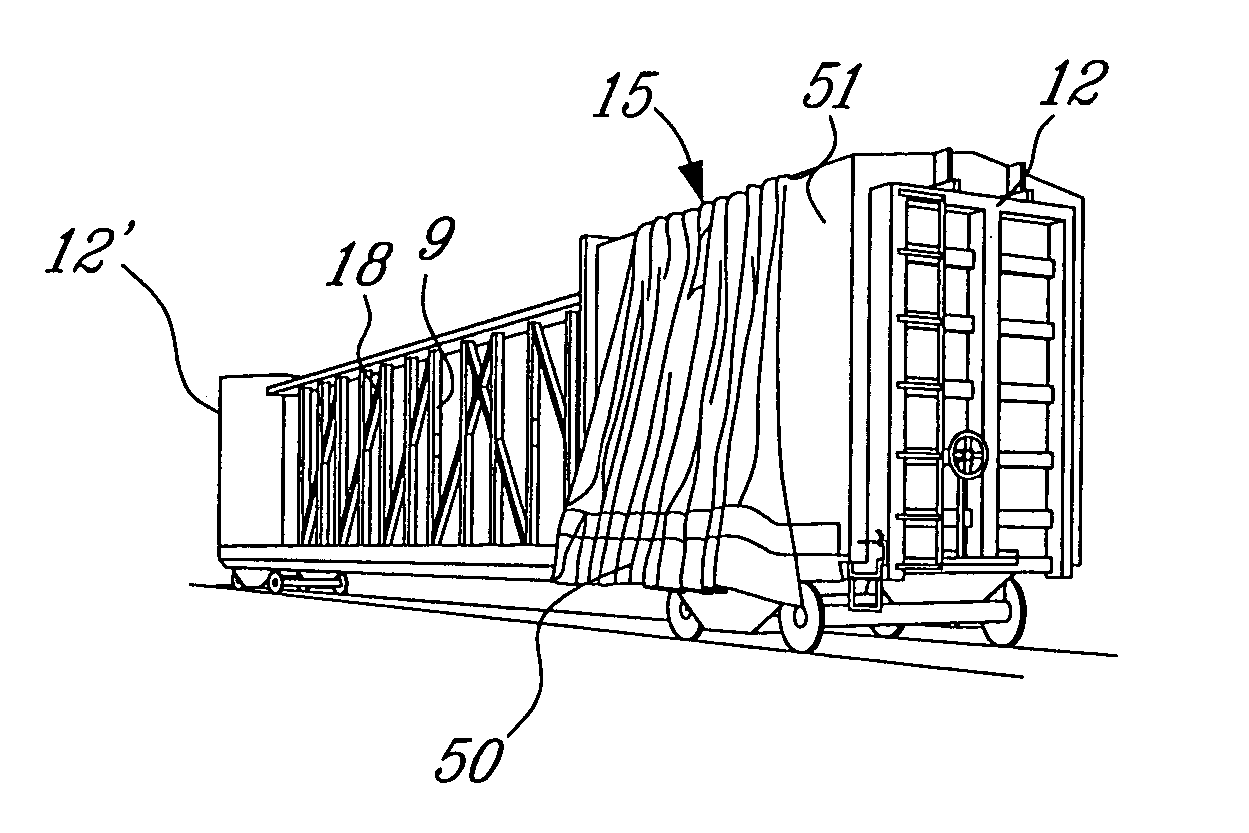

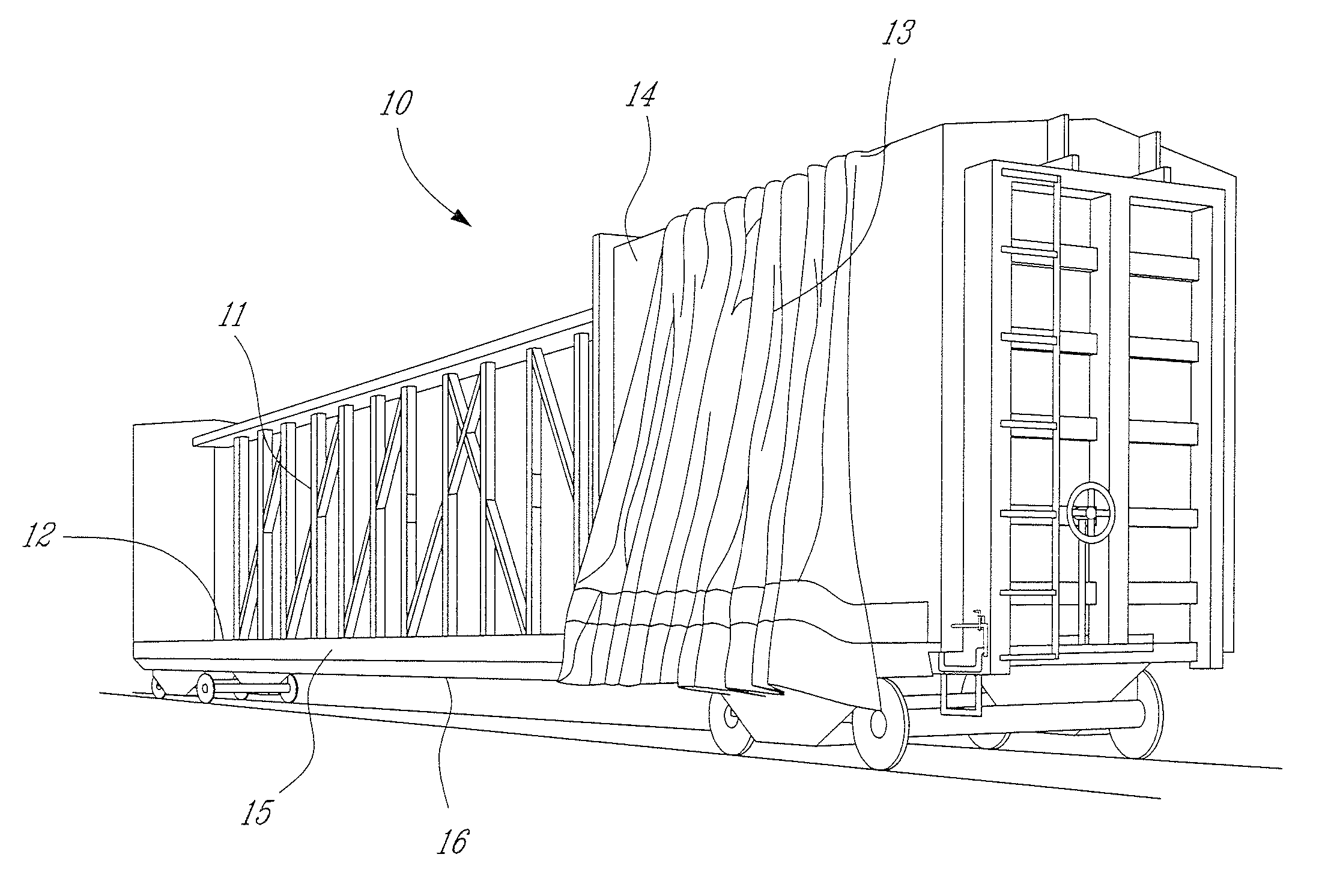

Slidable cover assembly for merchandise carrying vehicle platforms

ActiveUS20050274279A1Easy to assembleMove quicklySliding roofsTransportation itemsBraced frameLocking mechanism

A slidable cover assembly for merchandise carrying vehicle platforms is described. The cover assembly comprises a pair of opposed end support frames and a plurality of intermediate frames, each having a top carriage for displacement on a central horizontal top center beam member secured to the platform. Each end support frame and intermediate frames have a top tapered roof truss structure and opposed depending side members. The side members have a side rail engaging carriage at a lower end thereof for displaceable support engagement with a side rail secured to opposed sides of the platform. A tarp is secured to the end support frames and intermediate frames and displaceable therewith from a collapsed condition to an extended condition. Tarp displacement mechanisms are provided to displace the tarp side walls outwardly of the intermediate frames when the frames are displaced closer to one another from the extended condition to the collapsed condition. The end support frames have a vertical connecting wing flange disposed vertically along at least a portion of the opposed depending side members and adapted to be detachably secured to a locking mechanism secured to stationary opposed bulk head frames of the platform.

Owner:6866336 CANADA INC

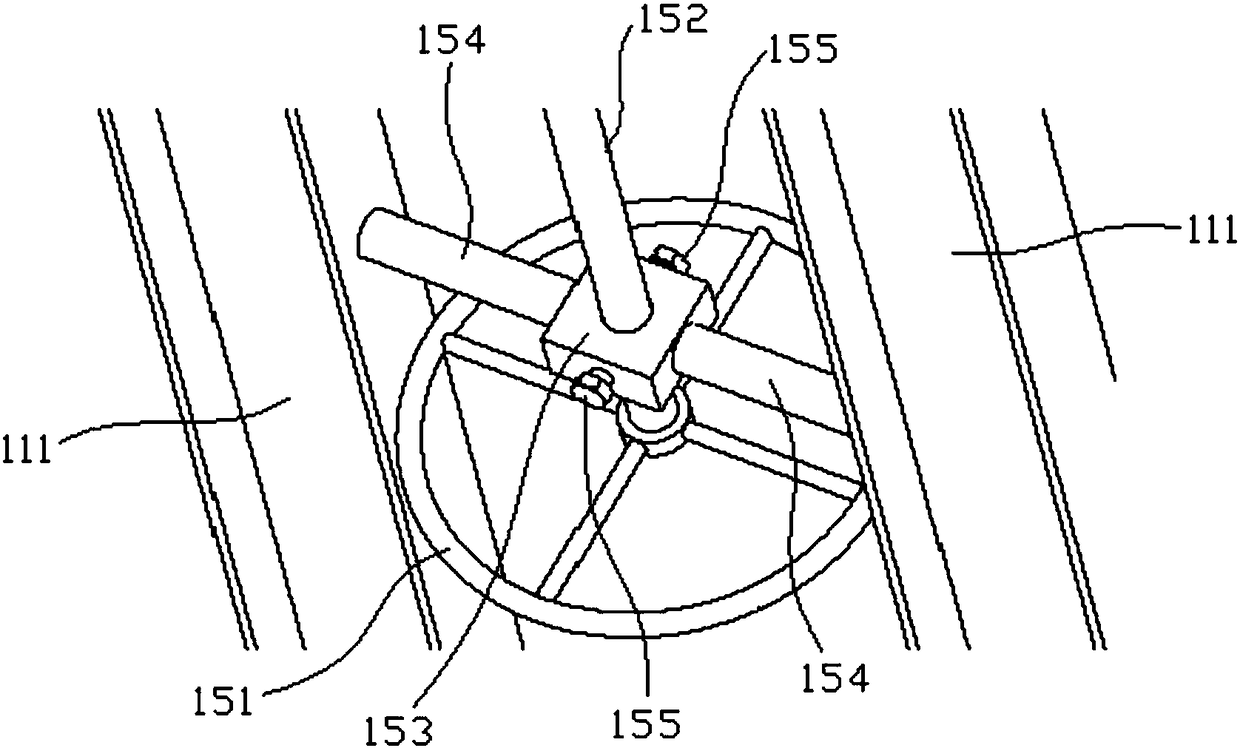

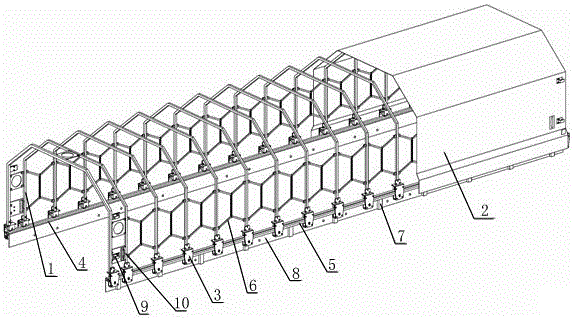

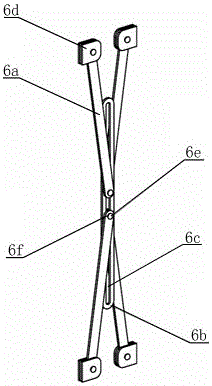

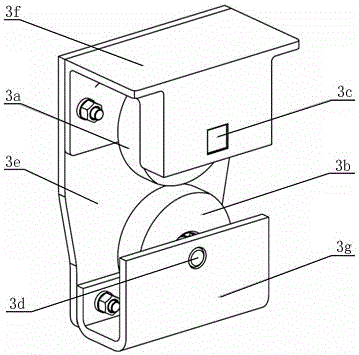

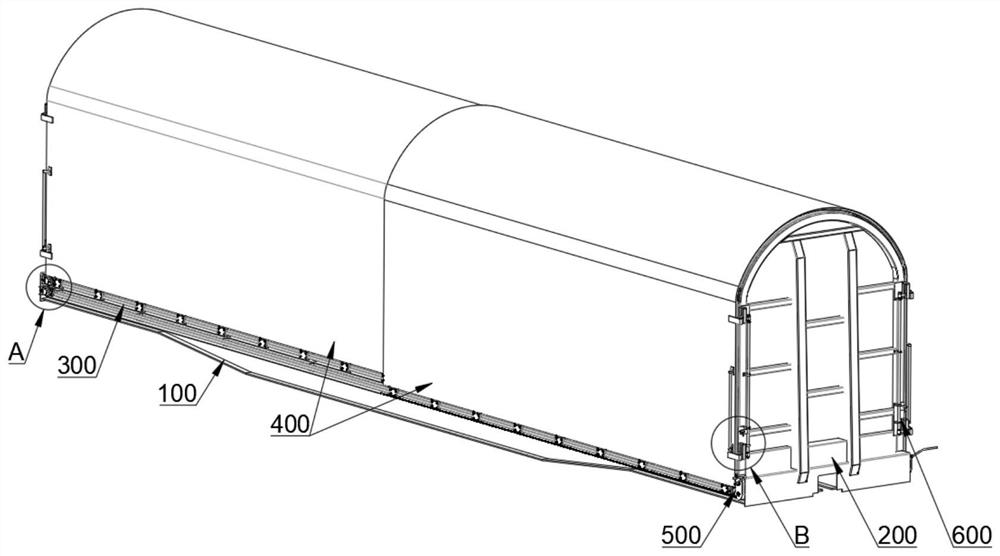

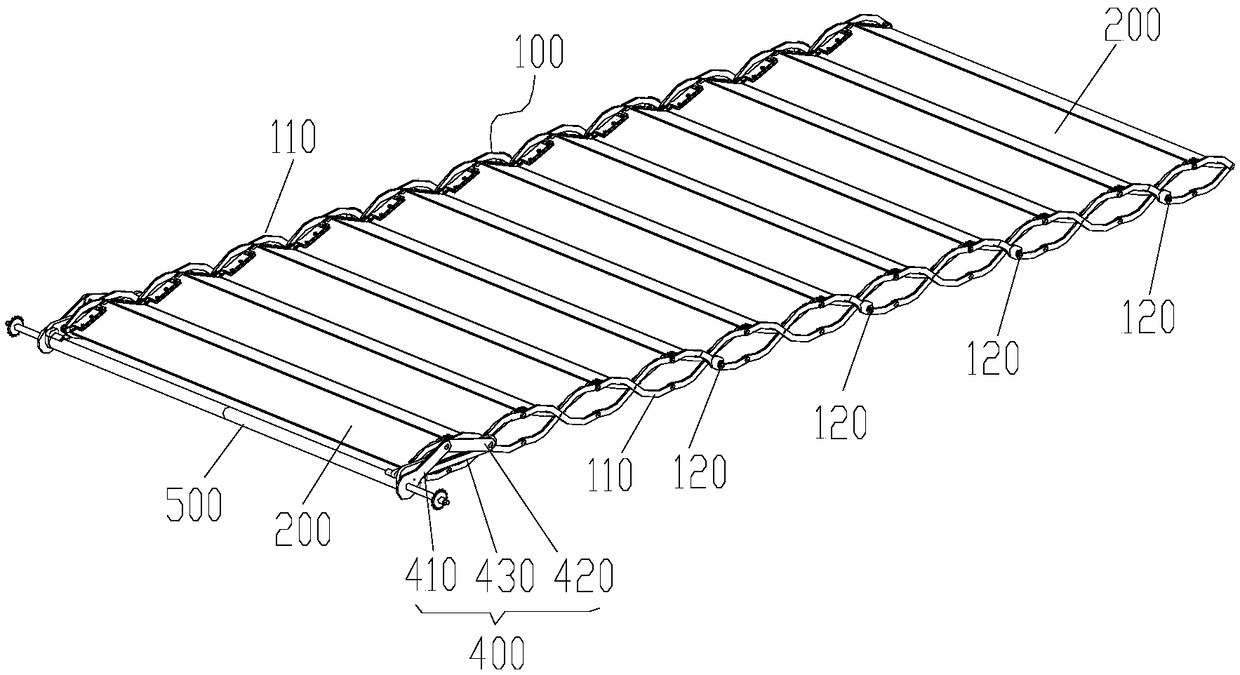

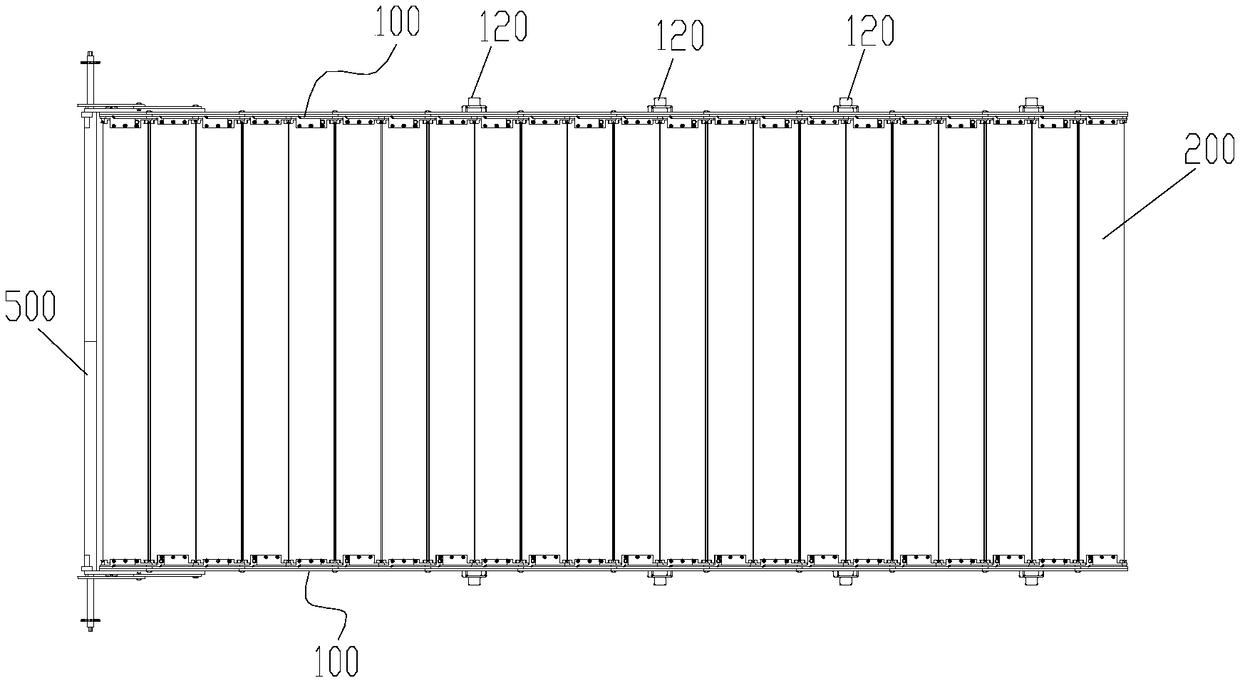

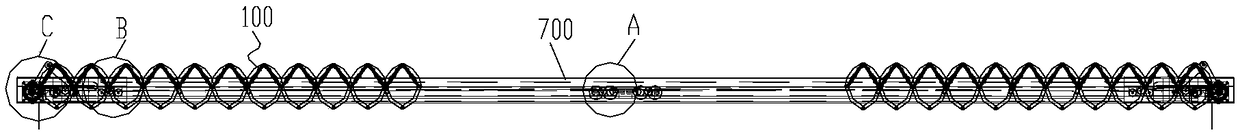

Push-pull telescopic movable awning used for railway flatcar

The invention discloses a push-pull telescopic movable awning used for a railway flatcar. The push-pull telescopic movable awning comprises a plurality of supports arranged in the longitudinal direction of a car body and awning cloth covering an arch supporting framework composed of the multiple supports. Pulley assemblies are arranged at the two ends of each support correspondingly. The pulley assemblies are in sliding fit with corresponding guide rails fixedly connected to upper side beams of the car. Articulating assemblies are arranged between every two adjacent supports. The multiple supports are connected together through the articulating assemblies, and push-pull telescoping of the multiple supports is driven by telescoping of the articulating assemblies. An awning cloth side wall of a push-pull telescopic structure is adopted, the opening degree of the movable side wall is large, the requirement of hoisting operation by a gantry crane is met, the awning can be suitable for loading of long and large cargos, and the awning has the characteristics of being low in self weight, simple in structure and convenient to maintain.

Owner:CRRC MEISHAN

Shield assembly for cargo space of a transport vehicle

A shield assembly is described for the cargo space of a transport vehicle wherein access to the cargo space is provided by a displaceable wall section mounted on a lower rail secured spaced from a lower side frame of the cargo space. The assembly comprises an elongated rectangular flexible seal guard having an elongated securable side edge section. The flexible seal guard has a width which is greater than a space defined between the rail and the lower side frame. The rail has a directional retention slot for immovably securing the securable side edge section of the flexible seal guard thereto whereby the flexible seal guard is supported for frictional engagement at an opposed free side edge against the lower side frame to substantially seal the space whereby to prevent foreign matter from entering into the cargo space.

Owner:6866336 CANADA INC

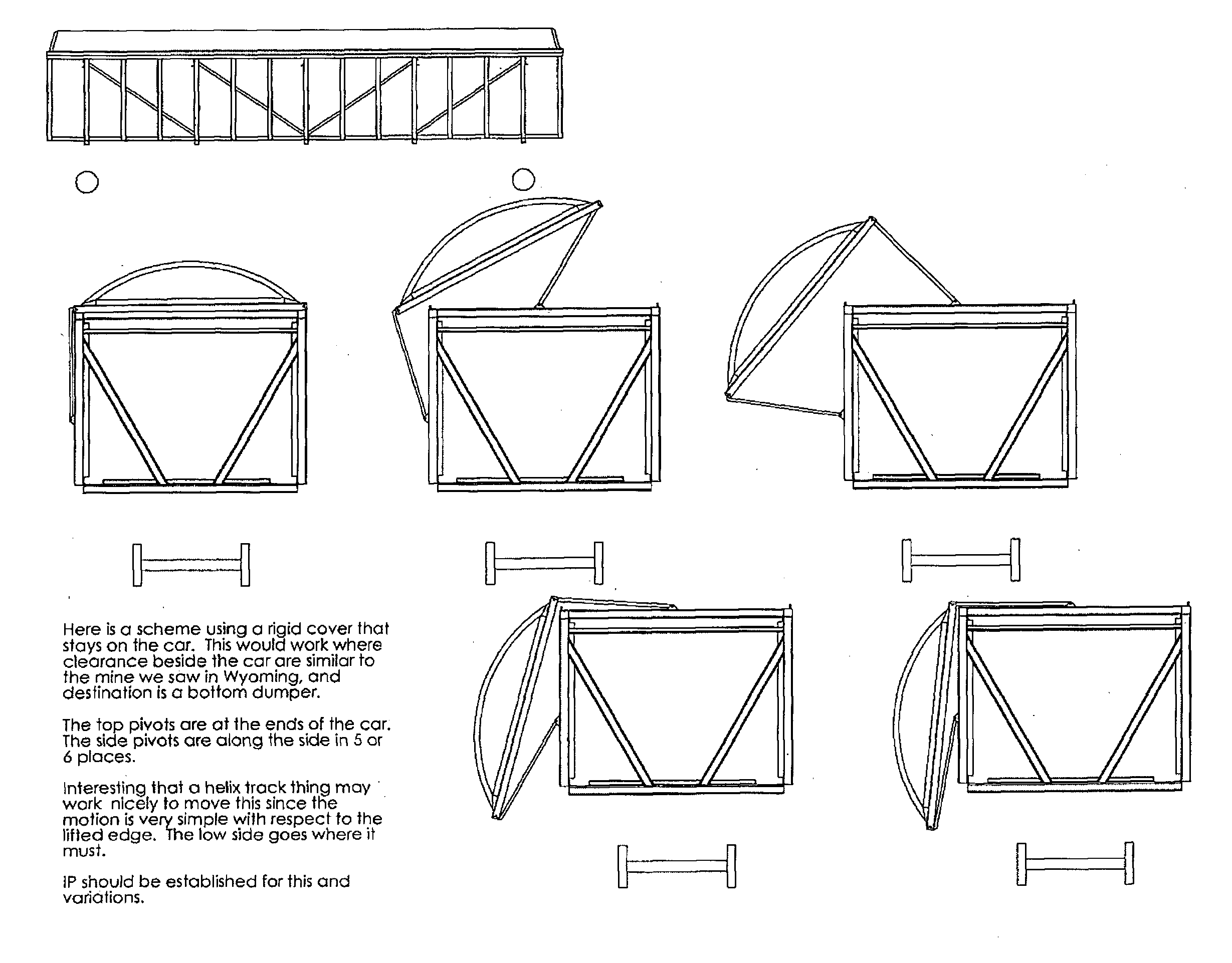

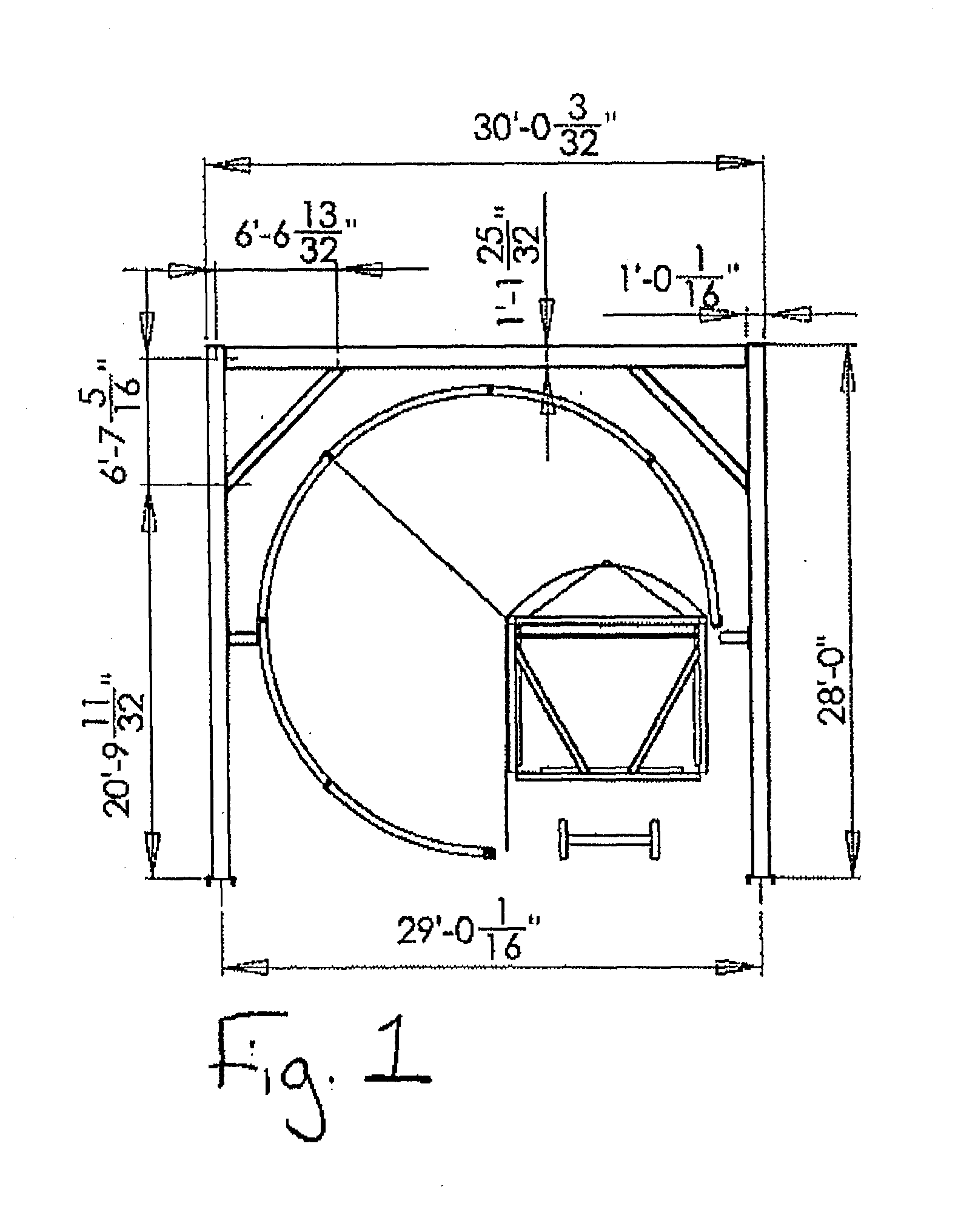

Railcar Cover Systems

A cover assembly for an open top railcar, the assembly having semi-rigid cover reversibly movable between a closed position atop the railcar and an open position alongside the railcar or separate from it. The cover may be connected to the railcar with hinge-latches or linkage arms which permit the cover to be held flat alongside the railcar in an open position, or removed from the railcar during loading and unloading. A load grooming device shapes the load of a loaded railcar to a selected contour. Opening and closing of covers may be continuous and automated, using curved tracks, cranes or mechanical arms to engage and open covers, and conveying devices or vehicles to handle covers during loading and unloading of railcars.

Owner:ECOFAB COVERS INT

Hopper car used to transport powdery goods

The invention discloses a hopper car used to transport powdery goods, and relates to railway transportation field. The hopper car includes up-opened car body, bottom door opening and closing mechanism, coupler-draft gear and bogie. The car body consists of two front and rear wall panels, two left and right wall panels and baseplate. A funnel plate is in the interior of the car body. Bottom door opening and closing mechanism consists of upper gear and lower gear. Car top set has dust-proof device, which includes dustproof cup and an electric drive mechanism for achieving dust-proof device opening and closing. This invention has the advantages of being moisture proof and dustproof, simple structure, high discharging efficiency and high drive accuracy. The hopper car fills a gap for depending electric driven in dustproof and discharge.

Owner:CRRC SHIJIAZHUANG CO LTD

Railcar cover

Owner:UNITED RAILCAR COVERS

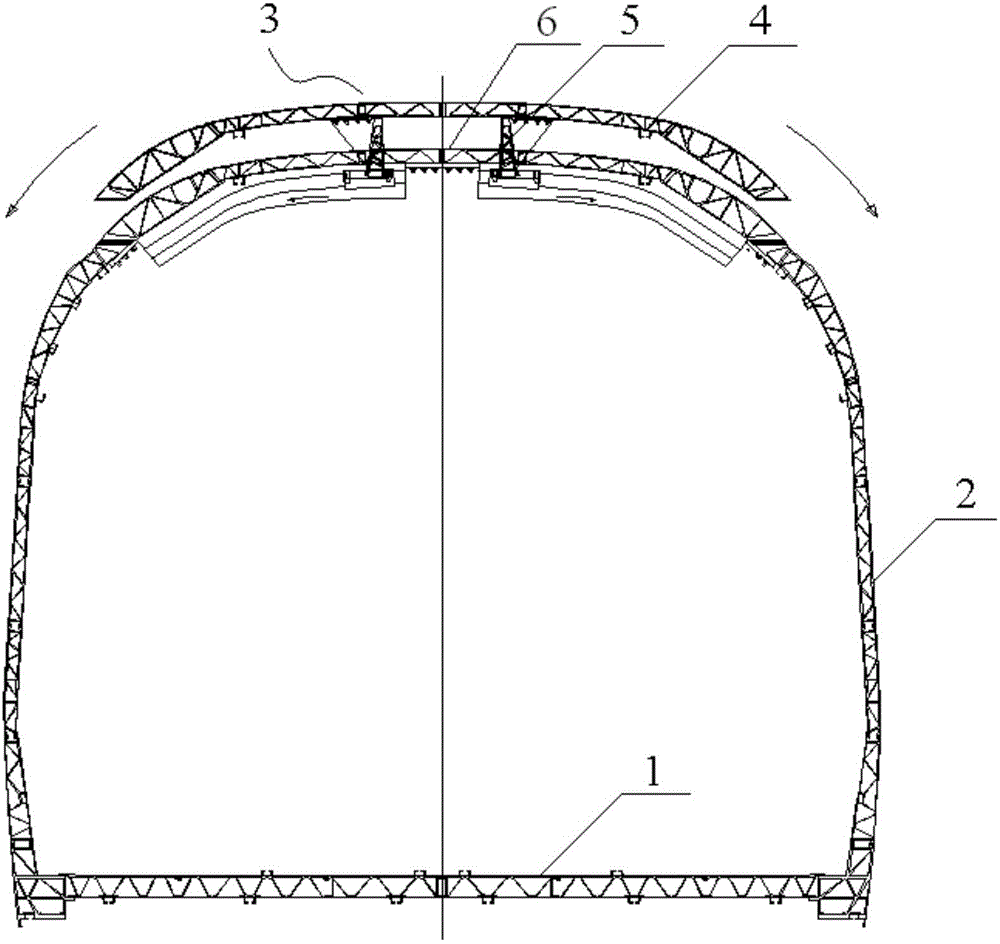

Motor train unit train body and motor train unit

InactiveCN106004909AEasy modular installationSave operating timeSliding roofsEngineeringMotor Drive Unit

The invention provides a motor train unit train body and a motor train unit. The motor train unit train body comprises a train bottom, side walls, end walls and a roof. The bottoms of the side walls are connected with the train bottom, and the ends of the side walls are connected with the end walls. The roof comprises movable top frames and driving devices, the driving devices can drive the movable top frames to be opened and closed, a chamber is jointly defined by the train bottom, the side walls, the end walls and the roof when the movable top frames are in a closed state, and the chamber is exposed when the movable top frames are in an opened state. The motor train unit train body is simple in structure, safe, reliable and convenient to operate; besides, modularized installation of large internal equipment is convenient.

Owner:CRRC TANGSHAN CO LTD

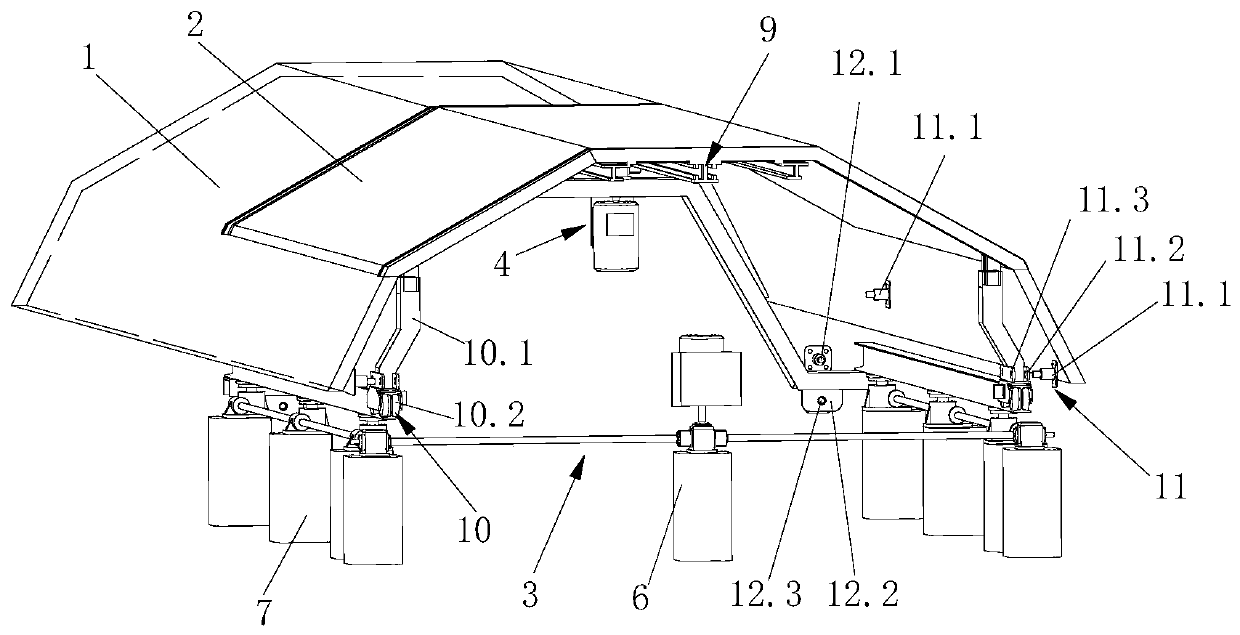

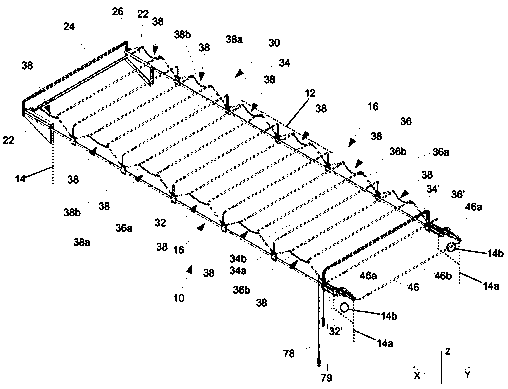

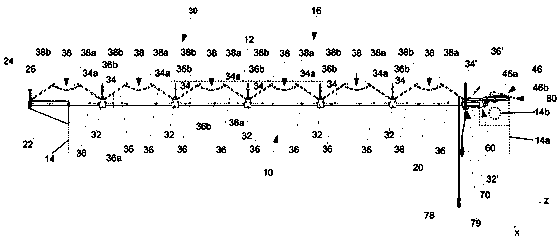

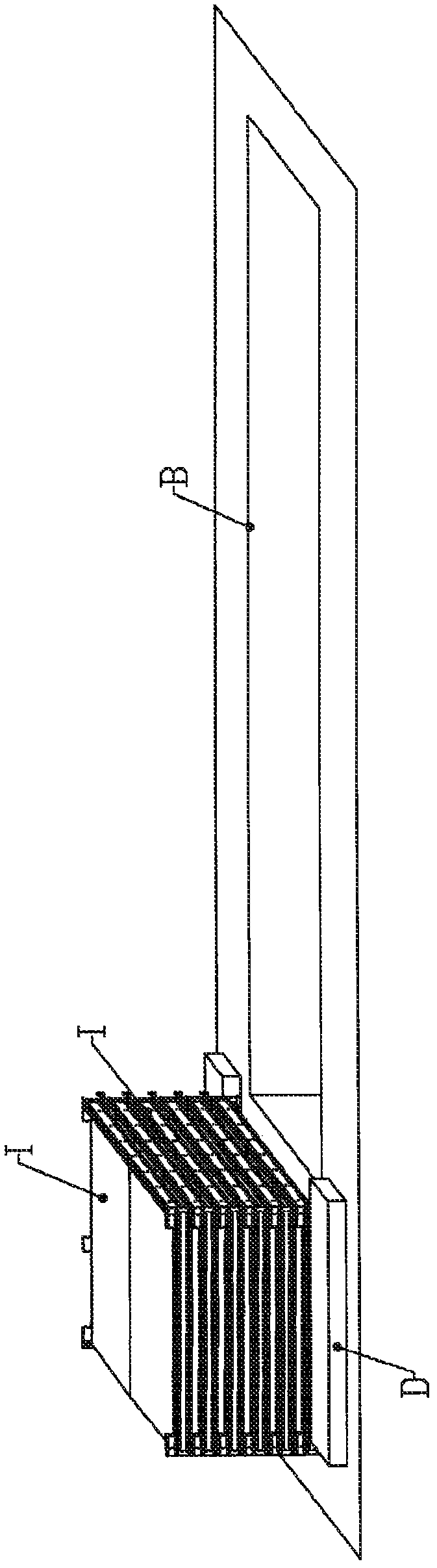

Tarpaulin structure

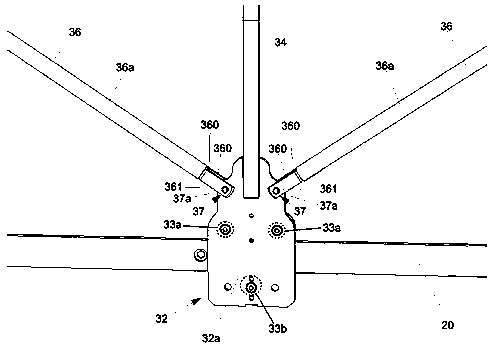

The invention relates to a tarpaulin structure for an understructure, such as a truck, trailer, semi-trailer, railway car, dump truck or container, comprising a folding-top frame (16) and a tarpaulin(12) made of weather-resistant material; the folding-top frame (16) includes a plurality of struts (34); at one end, each of the struts includes a carriage (32) that is movable along a guide (20); atleast one bracket (36) is selectively pivotally connected to a pair of opposite carriages (32; 32') of the strut or to the strut (34), said bracket (36) forming a tarpaulin folding aid along with a bracket (26; 36) of an adjacent strut (34), of a pair of opposite carriages (32; 32') or of a stationary part (24) of the folding-top frame (16). In order to create a light-weight tarpaulin structure that allows an understructure to be reliably covered, according to the invention, the adjacent brackets (26, 36) are coupled to each other by means of a cinematic connecting rod assembly (38) that foldswhen the folding-top frame (16) is collapsed.

Owner:EUROPEAN TRAILER SYSTEMS GMBH

Top-cap structure and railway wagon with top-cap structure

The invention provides a top-cap structure and a railway wagon with the top-cap structure. The top-cap structure comprises a vehicle frame, a travelling assembly and a dust cover, wherein the vehicleframe is provided with guide rails arranged oppositely; the travelling assembly is arranged on the vehicle frame, and can slide along the guide rails; the travelling assembly comprises a top-cap crossbeam and a guide frame connected with the two ends of the top-cap cross beam; the guide frame comprises a frame, an idler wheelrollablyarranged in the frame and a positioning block arranged relativeto the axial direction of the idler wheel, the positioning block is arranged on the frame, a semi-closed structure is enclosed by the positioning block and the idler wheel, and is used for installingthe guide rails, and the idler wheel can slide along the guide rails. The displacement of the guide frame is limited through matching of the positioning block and the guide rails, it is guaranteed that the guide frame cannot be separated from the guide rails in the harsh environment such ad gale or in the case of irregularity of the guide rails, thus the guide frame can slide along the guide railsreliably, then the safe operation of the top-cap structure is ensured, and the usability of the top-cap structure is improved.

Owner:SHENHUA RAIL & FREIGHT WAGONS TRANSPORT +1

Basin covering device

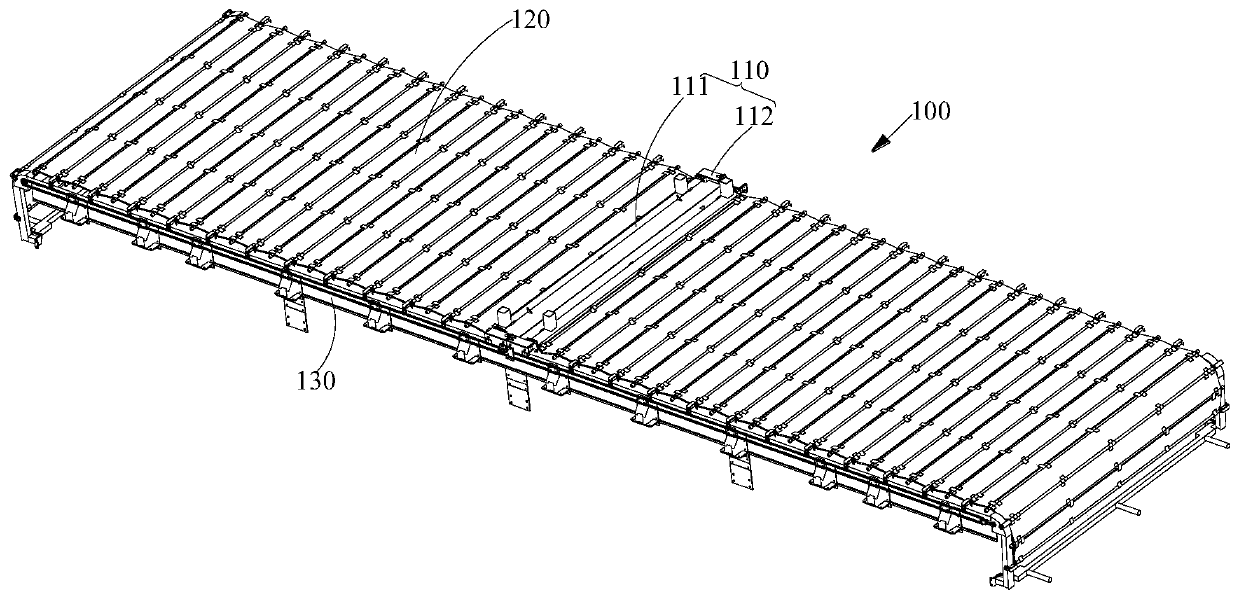

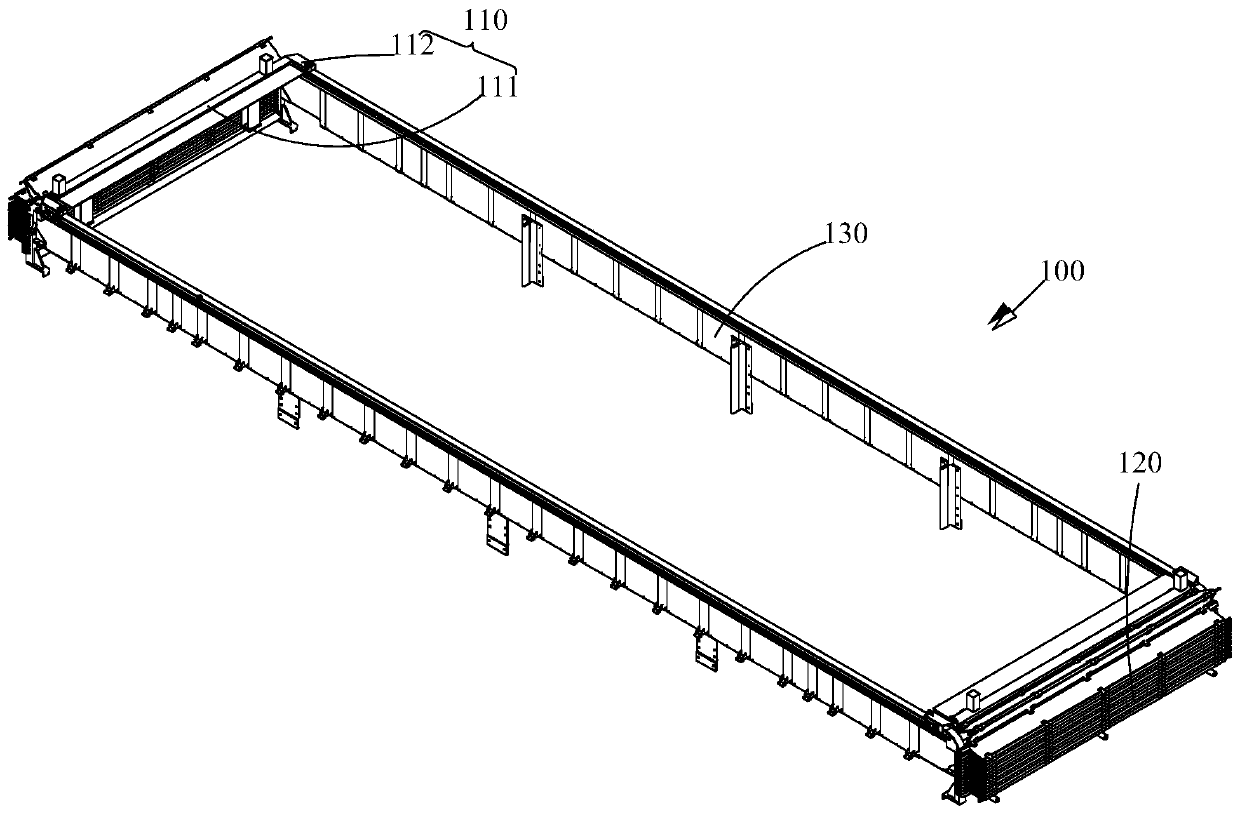

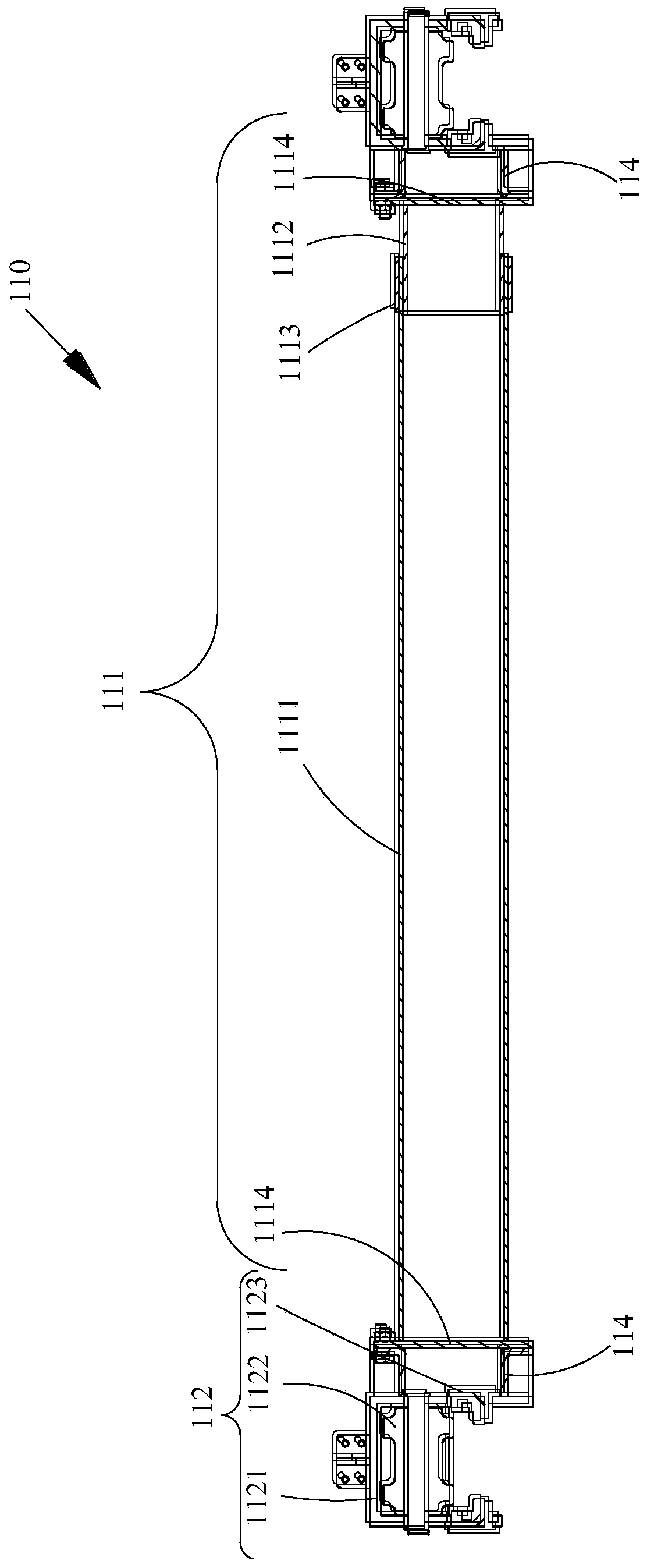

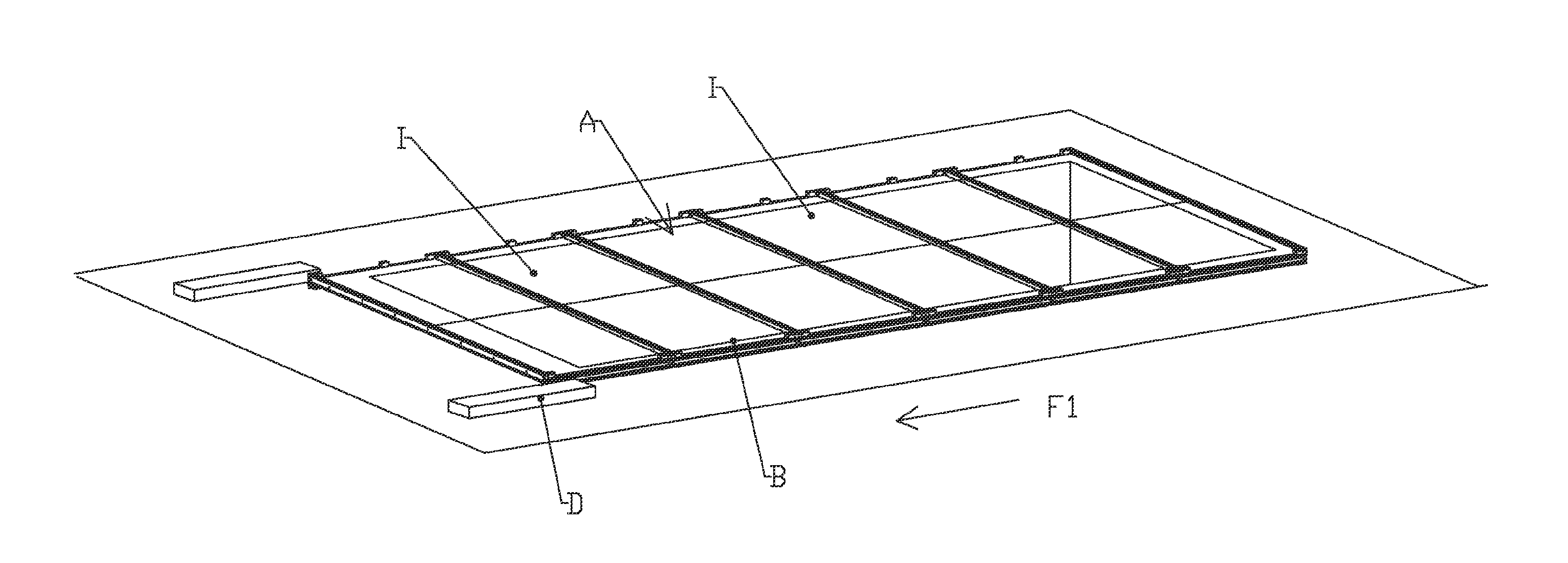

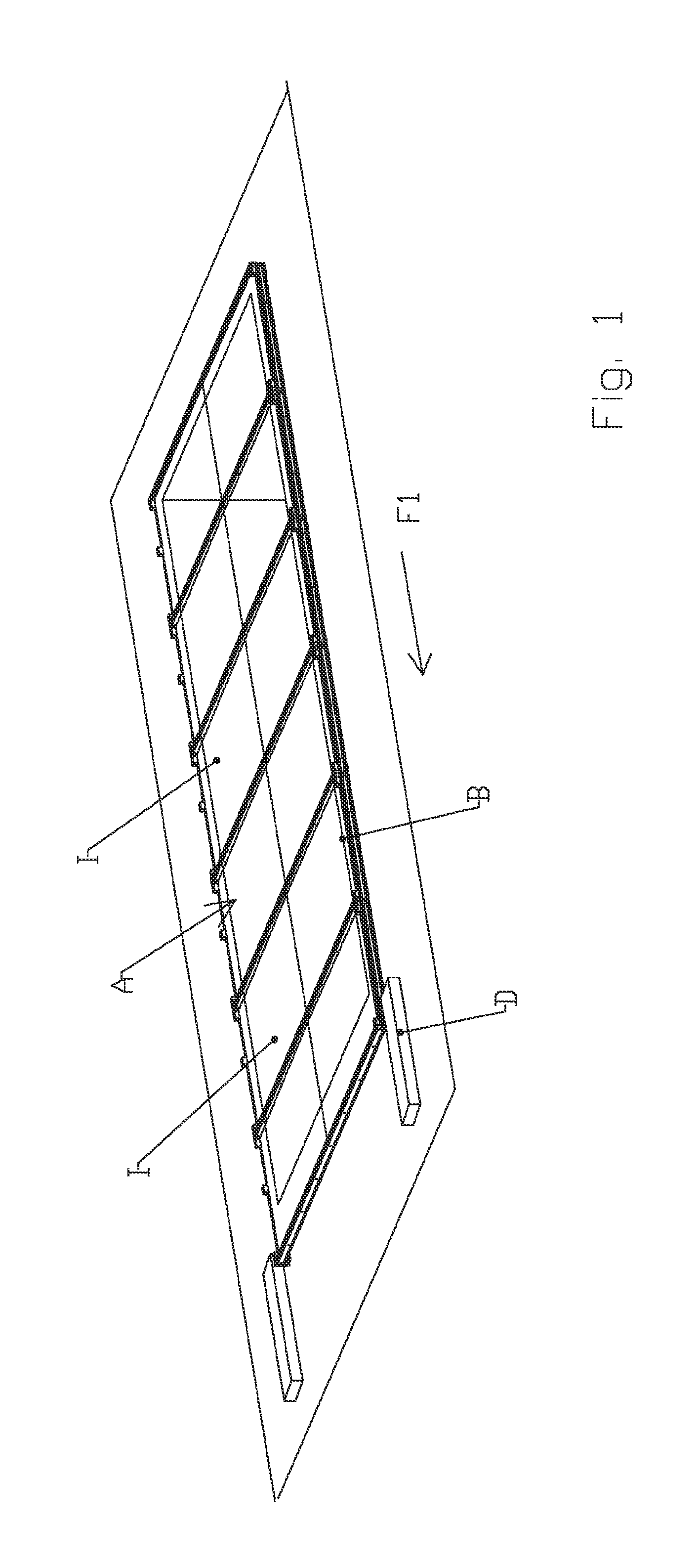

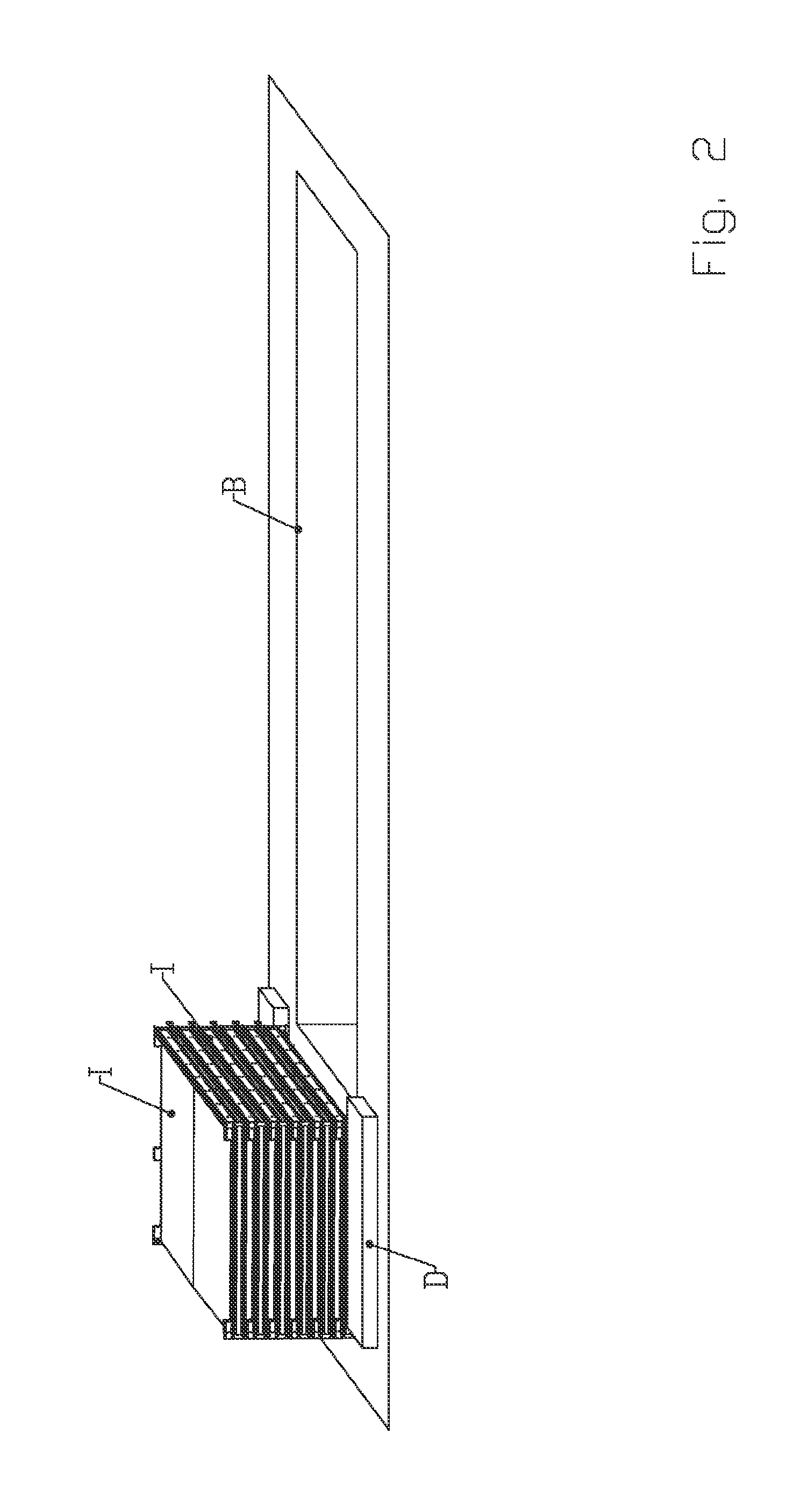

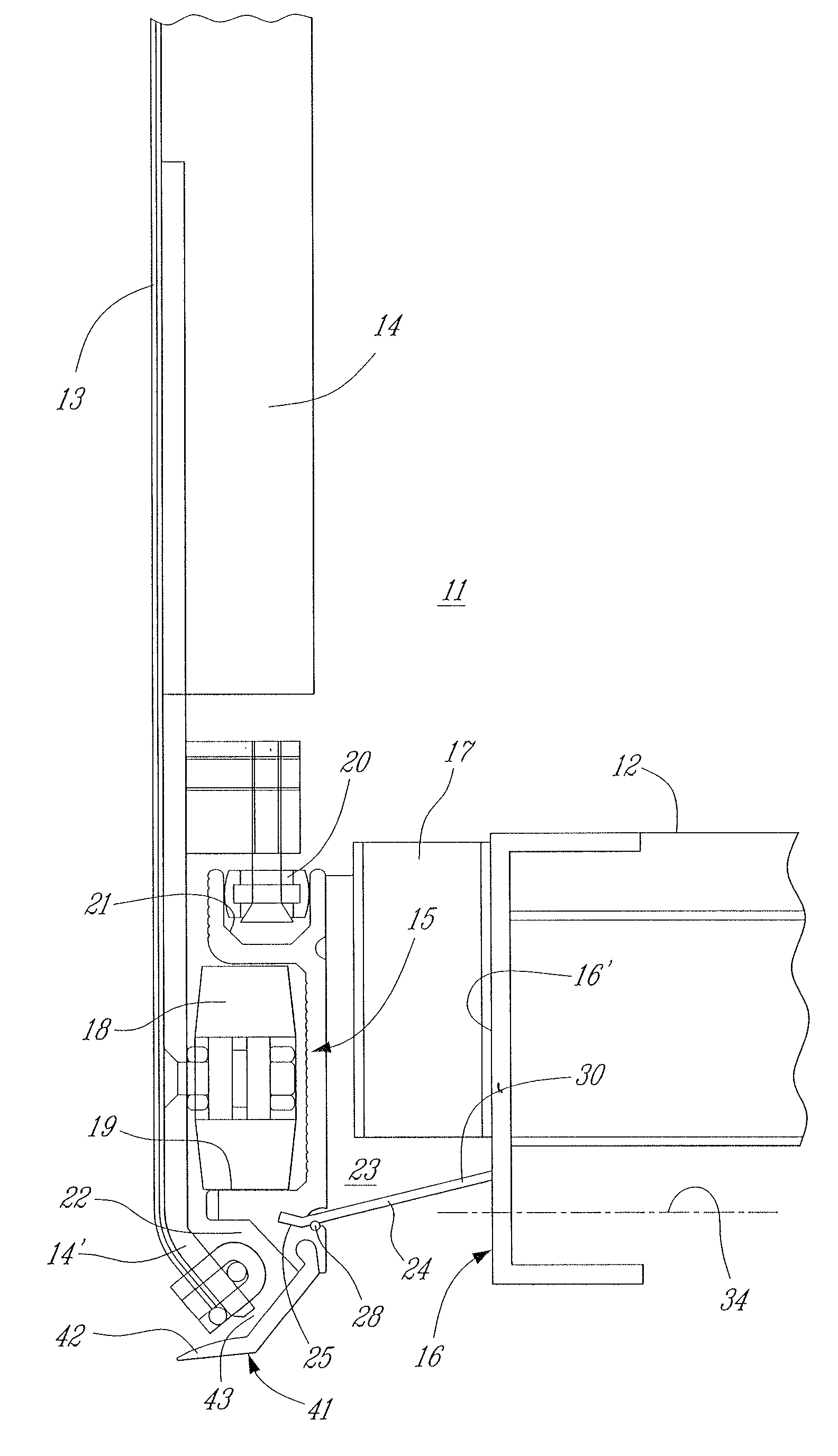

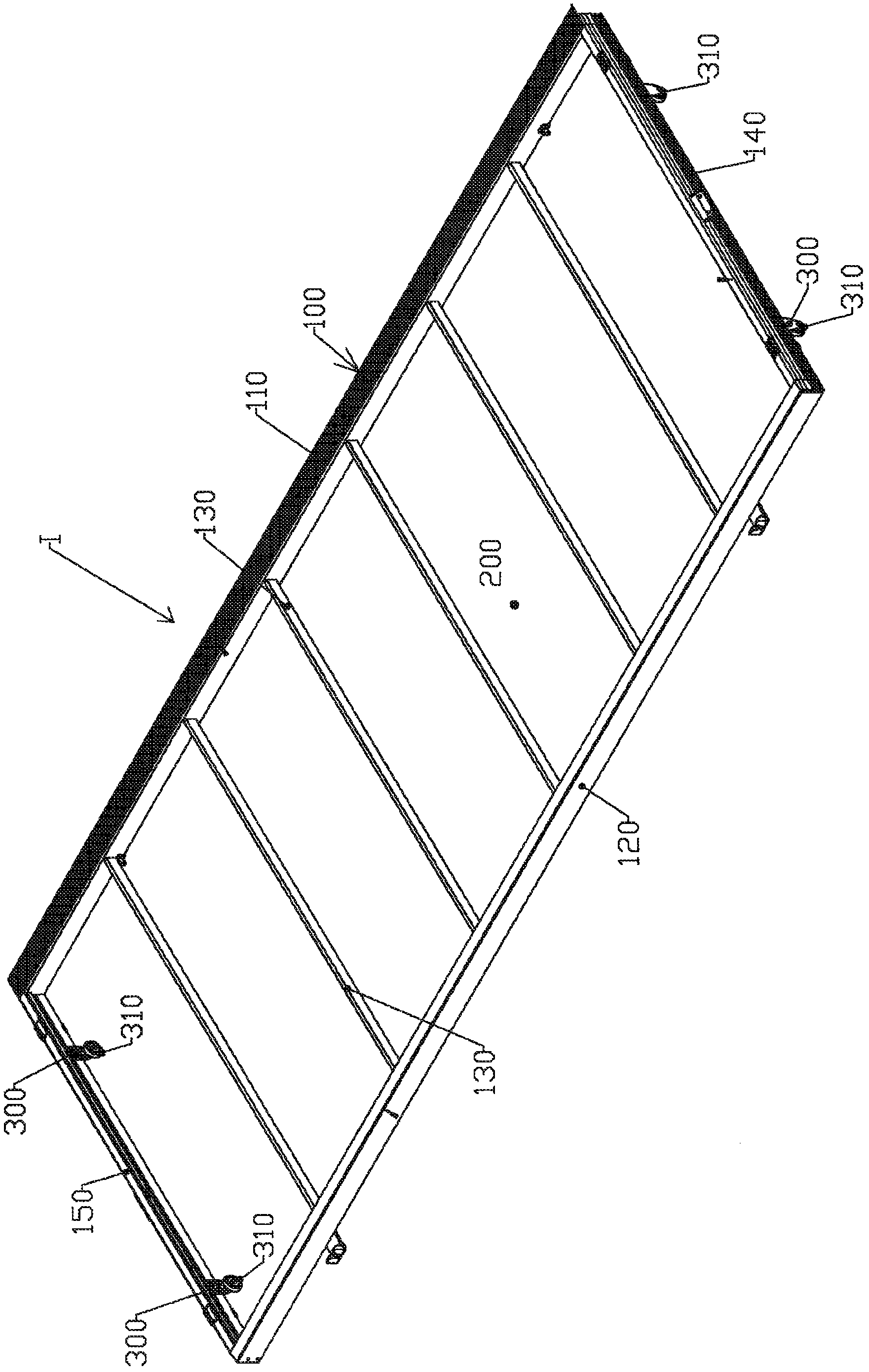

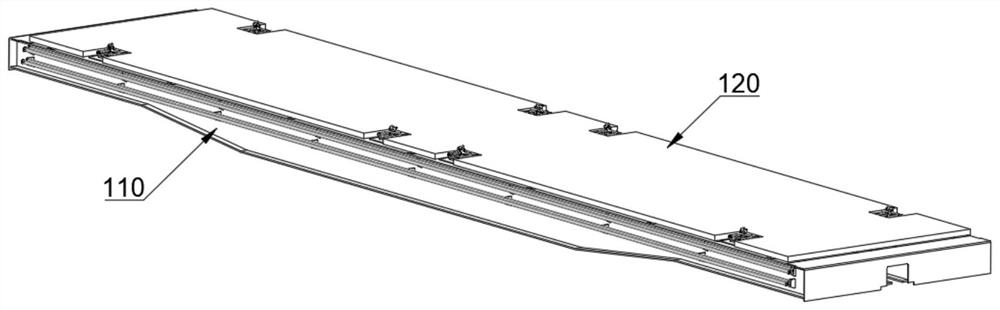

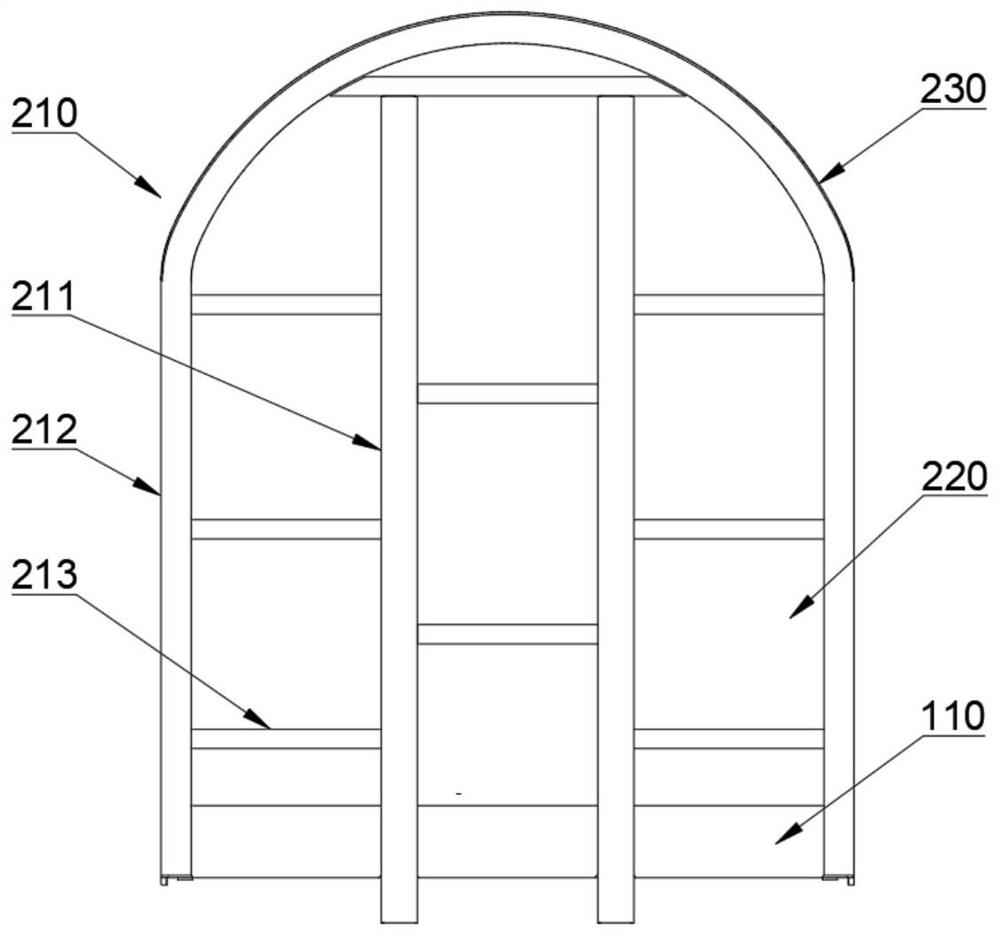

The invention relates to a shelter (A) for, for example, a pool- or spa-type recreational basin (B) that is formed of roofing elements (I) and is capable of passing from a deployed position, where the roofing elements are placed in a juxtaposed manner and the basin is covered, to a stacked position, where the roofing elements are placed one over the other and the basin is partially or completely uncovered, said roofing elements (I) including two transverse sections (110 and 120) cross-tied with longitudinal cross-pieces (130), with the so-called extreme cross-pieces (140 and 150) placed on the ends of said sections (110 and 120) that eventually rest on the rim of the basin (B) through a rolling means (300) that is formed of wheels (310) and remarkable in that the wheels (310) are mounted on wheel holders (320) that are foldably mounted relative to the extreme cross-pieces (140 and 150) so as to enable the folding away thereof during the stacking of the roofing elements (I).

Owner:ABRISUD

Shield assembly for cargo space of a transport vehicle

A shield assembly is described for the cargo space of a transport vehicle wherein access to the cargo space is provided by a displaceable wall section mounted on a lower rail secured spaced from a lower side frame of the cargo space. The assembly comprises an elongated rectangular flexible seal guard having an elongated securable side edge section. The flexible seal guard has a width which is greater than a space defined between the rail and the lower side frame. The rail has a directional retention slot for immovably securing the securable side edge section of the flexible seal guard thereto whereby the flexible seal guard is supported for frictional engagement at an opposed free side edge against the lower side frame to substantially seal the space whereby to prevent foreign matter from entering into the cargo space.

Owner:6866336 CANADA INC

Basin covering device

The invention relates to a shelter (A) for, for example, a pool- or spa-type recreational basin (B) that is formed of roofing elements (I) and is capable of passing from a deployed position, where the roofing elements are placed in a juxtaposed manner and the basin is covered, to a stacked position, where the roofing elements are placed one over the other and the basin is partially or completely uncovered, said roofing elements (I) including two transverse sections (110 and 120) cross-tied with longitudinal cross-pieces (130), with the so-called extreme cross-pieces (140 and 150) placed on the ends of said sections (110 and 120) that eventually rest on the rim of the basin (B) through a rolling means (300) that is formed of wheels (310) and remarkable in that the wheels (310) are mounted on wheel holders (320) that are foldably mounted relative to the extreme cross-pieces (140 and 150); so as to enable the folding away thereof during the stacking of the roofing elements (I).

Owner:ABRISUD

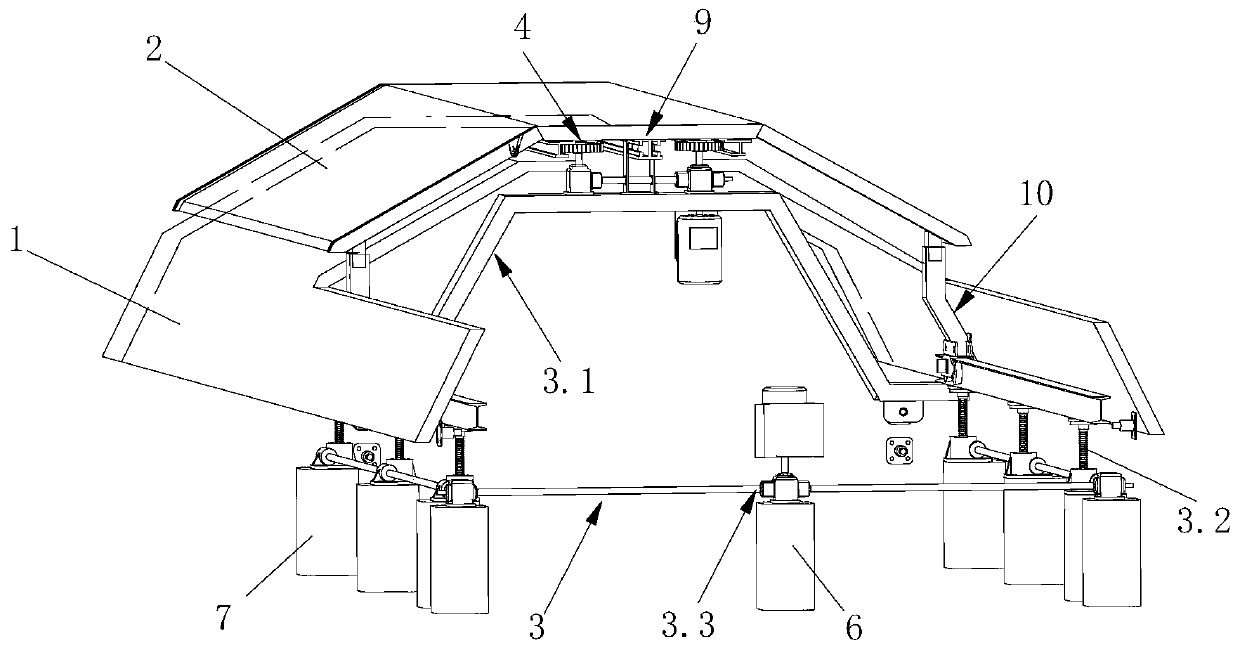

Movable top cover system and railway open wagon

PendingCN110203235ASimple structureNo energy consumptionSliding roofsEngineeringMechanical engineering

The invention provides a movable top cover system and a railway open wagon. The movable top cover system involves a top cover unit which can be unfolded or folded, a sliding rail arranged at the top end of the open wagon, and cover shifting devices arranged on the two sides of a railway, the top cover unit can slide along the sliding rail to be folded or unfolded, so that opening or closing of thetop of the open wagon is completed, the cover shifting device can stop the top cover unit at the top of the open wagon during running, so that the top cover unit can be folded or unfolded. Accordingto the movable top cover system, the kinetic energy of the open wagon is converted into the force of opening or closing the top cover unit, so that the top of the open wagon can be completely opened,the structure is simple, and no extra energy is consumed.

Owner:SHENHUA RAIL & FREIGHT WAGONS TRANSPORT +1

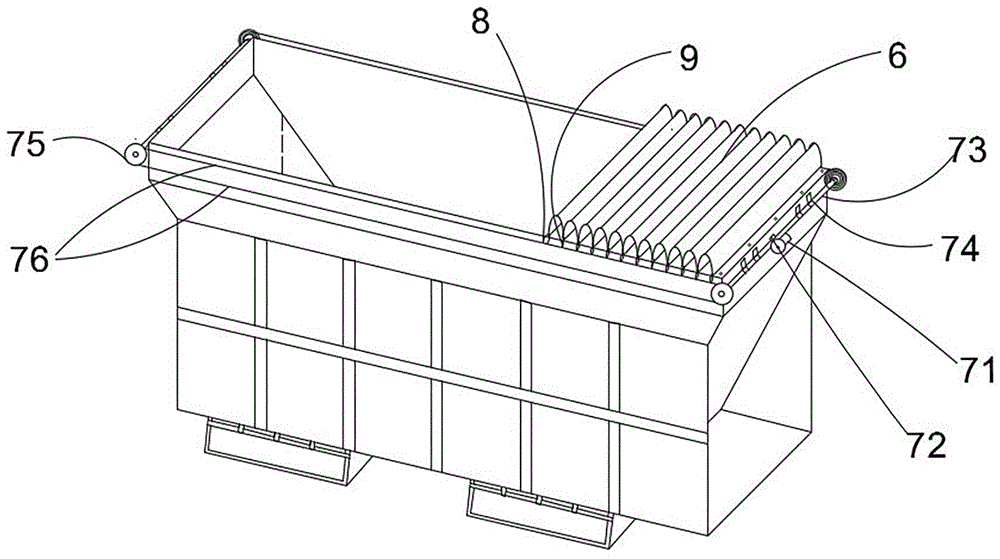

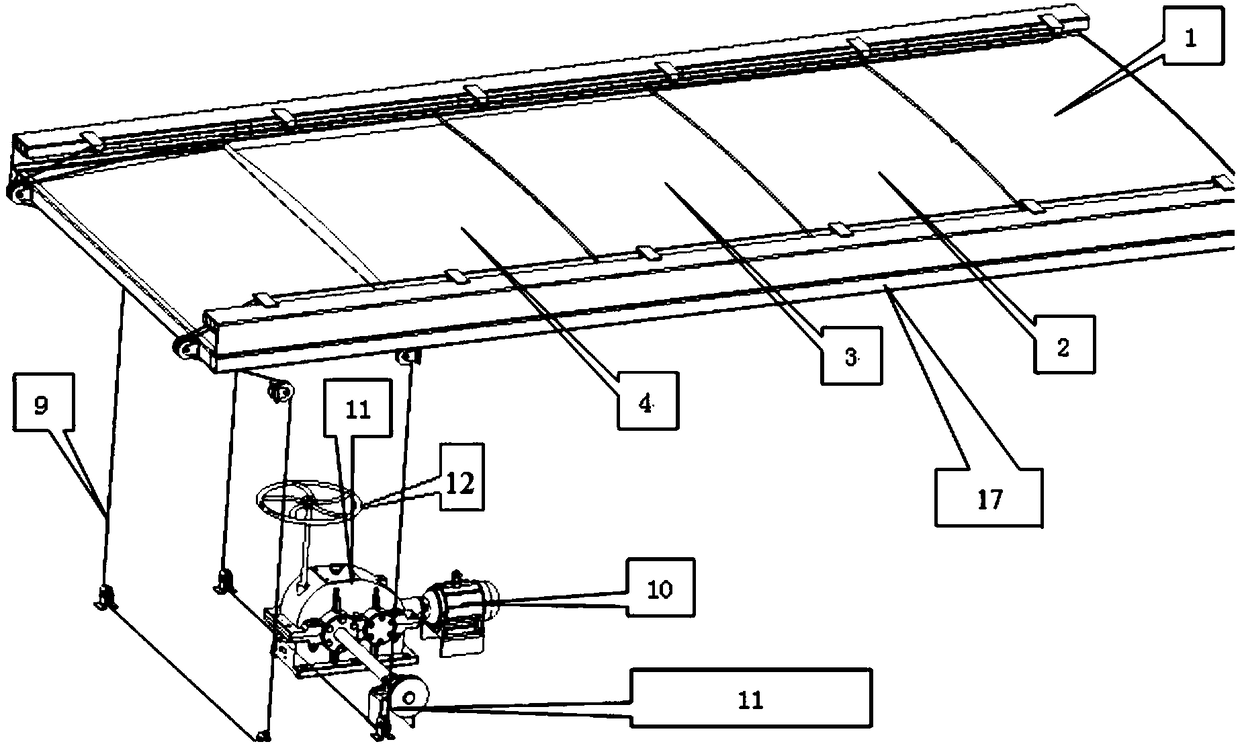

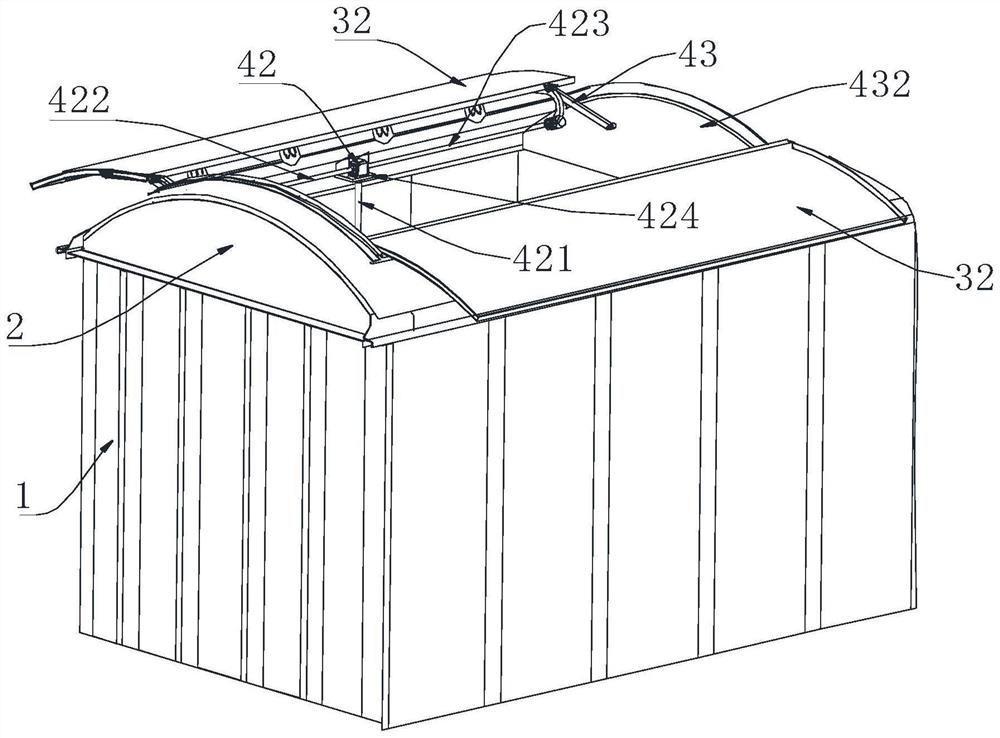

Large-opening folding type moving top cover of railway wagon

The invention provides a large-opening folding type moving top cover of a railway wagon, which comprises guide rail seats, wherein the guide rail seats are arranged at two sides of the top of the wagon, and each guide rail seat comprises a plurality of guide rails; a plurality of top plates, wherein two sides of each top plate are arranged in the corresponding guide rails in a sliding manner, andblocking irons are arranged at two ends of each top plate; a transmission part, wherein the transmission part comprises a hoisting pulley, a steel wire rope and a driving device, one end of the hoisting pulley is connected with the guide rail seats, the driving device is arranged at the end part of the railway wagon, the steel wire rope is wound on the hoisting pulley and the output shaft of the driving device, an enclosed winding is formed, a stop block is arranged on the steel wire rope, the driving device drives the steel wire rope to rotate, and the stop block can be contacted with the stop iron to drive the plurality of top plates to fold or unfold. The large-opening folding type moving top cover of the railway wagon is large in opening degree, small in opening and closing occupied space and strong in rigidity.

Owner:CRRC TAIYUAN CO LTD

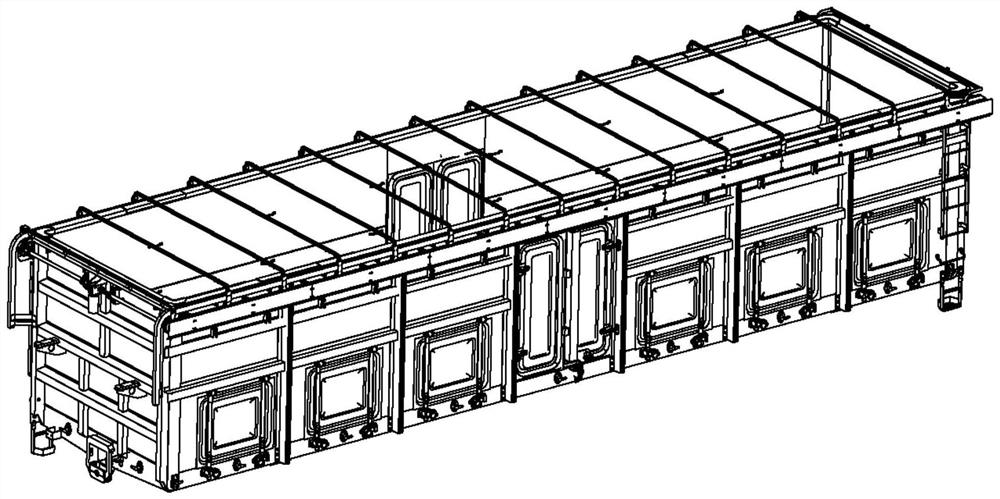

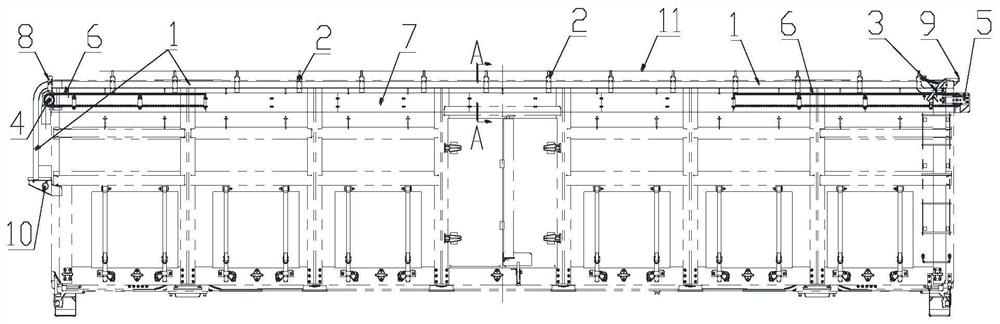

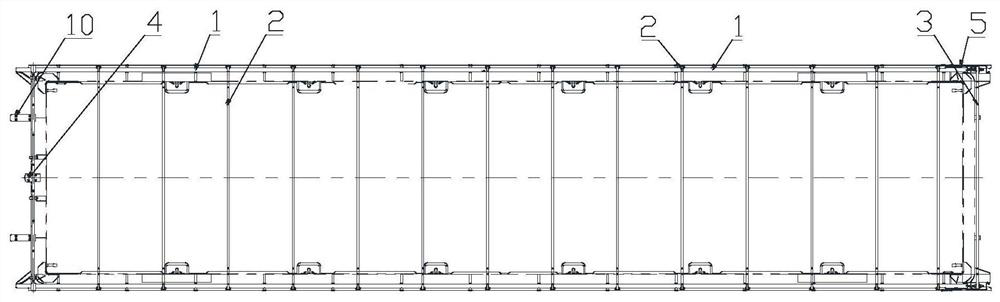

Multipurpose railway boxcar with flatcar function

ActiveCN112550324AGive full play to the advantages of transportationAvoid sun exposureRailway transportAxle-box lubricationStructural engineeringMechanical engineering

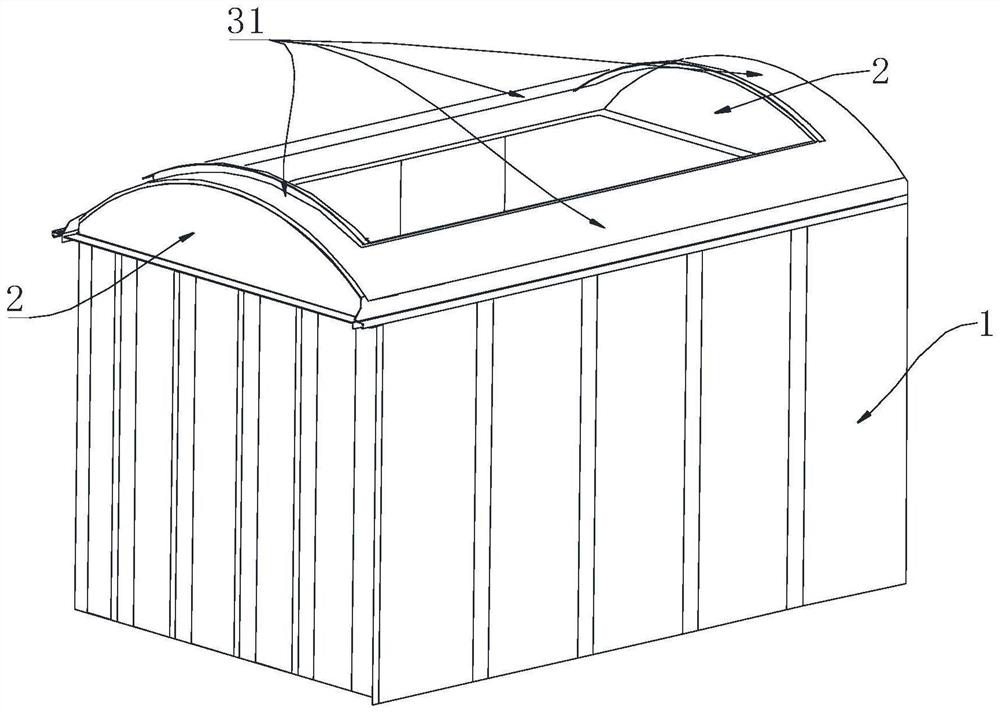

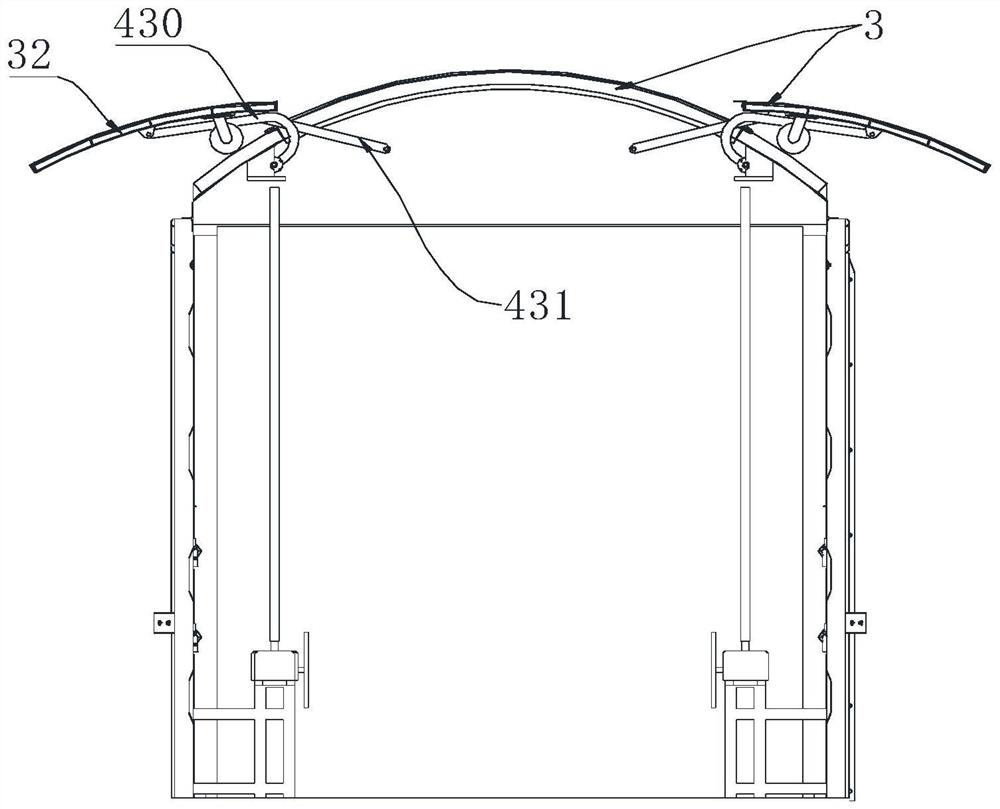

The invention discloses a multipurpose railway boxcar with a flatcar function. The multipurpose railway boxcar comprises a flatcar body, two end wall assemblies, two pairs of boxcar body guide rails and two sections of movable boxcar bodies. The two end wall assemblies are arranged at the two ends of the upper portion of the flatcar body correspondingly. The two shed body guide rails in each pairare arranged on the two sides of the flatcar body respectively. The two movable shed bodies are arranged above the flatcar body and located between the two end wall assemblies. Each section of the movable shed body is connected to the pair of shed body guide rails in a sliding manner through a plurality of rollers arranged on two sides of the lower part of the movable shed body, so that the movable shed body can slide along the pair of shed body guide rails; the size of the cross section of one of the two movable shed bodies is small, and the whole movable shed body can be nested in the othermovable shed body; the multipurpose railway boxcar further comprises a boxcar body transmission device and a boxcar body locking device. The boxcar has the functions of the boxcar and the shared flatcar, the transportation advantages of the boxcar and the shared flatcar can be brought into full play, and vehicle idle time is shortened.

Owner:CRRC YANGTZE GRP CO LTD

Carriage and vehicle with same

The invention provides a carriage and a vehicle with the same. The the carriage comprises: a carriage body, wherein the top of the carriage body is provided with an opening, and the carriage body is provided with a first chute; a movable top cover which covers the opening in an openable and closable manner, wherein the movable top cover has an open state and a closed state; a first swing rod, wherein the first end of the first swing rod is hinged to the movable top cover, and the second end of the first swing rod is hinged to the first chute; and a driving mechanism which is arranged in the carriage body and comprises a driving piece, wherein the driving piece is in driving fit with the first swing rod to drive the first swing rod to swing so as to drive the movable top cover to be switched between the open state and the closed state. According to the technical scheme, the problem that in the prior art, the opening degree of a loading opening is small, and loaded goods are limited is effectively solved.

Owner:CRRC QIQIHAR ROLLING CO LTD

Railcar Cover Systems

A cover assembly for an open top railcar, the assembly having semi-rigid cover reversibly movable between a closed position atop the railcar and an open position alongside the railcar or separate from it. The cover may be connected to the railcar with hinge-latches or linkage arms which permit the cover to be held flat alongside the railcar in an open position, or removed from the railcar during loading and unloading. A load grooming device shapes the load of a loaded railcar to a selected contour. Opening and closing of covers may be continuous and automated, using curved tracks, cranes or mechanical arms to engage and open covers, and conveying devices or vehicles to handle covers during loading and unloading of railcars.

Owner:LOW TREVOR +3

Inlet closure system

ActiveUS9783212B2Extended service lifeAvoid obstructionTiltable roofsTank wagonsActuatorIntermediate point

Owner:DRAX POWER

Railcar cover

Owner:UNITED RAILCAR COVERS

Top cover device and rail vehicle having the same

PendingCN109263676ANot easy to dropNot easy to loseSliding roofsElectrical and Electronics engineeringEngineering

Owner:CRRC QIQIHAR ROLLING CO LTD

Goods truck and movable top cover device of goods truck

The invention provides a goods truck and a movable top cover device of the goods truck; The movable top cover device of the goods truck includes a first top cover, and an opening and closing mechanism; the first top cover is arranged at the edge of a vehicle body of the goods truck, and the first top cover is a foldable part; the opening and closing mechanism includes a drive device, and under thedriving effect of the drive device, the first top cover has a closed state in which the first top cover can spread or a starting state in which the first top cover can retract in the longitudinal direction of the vehicle body. According to the technical scheme, the movable top cover device is open in the longitudinal direction of a vehicle frame, a large loading space is provided, and since the first top cover is the foldable part, and space is saved in the height direction.

Owner:CRRC QIQIHAR ROLLING CO LTD

Longitudinal telescopic railway wagon top cover

The invention discloses a longitudinal telescopic railway wagon top cover. The top cover comprises a rail assembly, a sliding block and shed rod system and a driving system. Rails are integrally arranged on two sides of a side wall of a vehicle body in an inverted-L shape, and the sliding block and shed rod system comprises a tail sliding block and shed rod assembly, a driven sliding block and shed rod assembly and a driving sliding block and shed rod assembly which operate along the rails. Each assembly comprises a shed rod for supporting and connecting awning cloth and a sliding block whichruns along the rails and supports the shed rod; power sources such as a motor or a hydraulic motor and the like are adopted, the driving sliding block and shed rod assembly are driven by a transmission mechanism to move on the rails, and the awning cloth covers an open top; and when the top cover is opened, the transmission mechanism drives the driving sliding block to directly act on the driven sliding block, and recycling of the shed rod and the awning cloth is achieved. Due to arrangement of the rails, the shed rod can be conveniently placed on an outer side of an end wall of a wagon body after being retracted, and the wagon body is fully opened to adapt to tippler unloading conditions; and the top cover is made of light-weight soft awning cloth, the weight is light, and maintenance cost is low.

Owner:CRRC MEISHAN

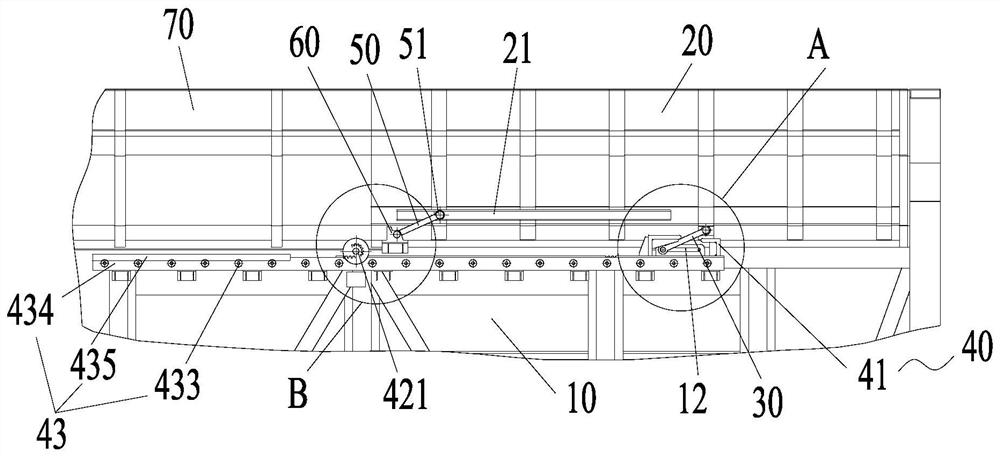

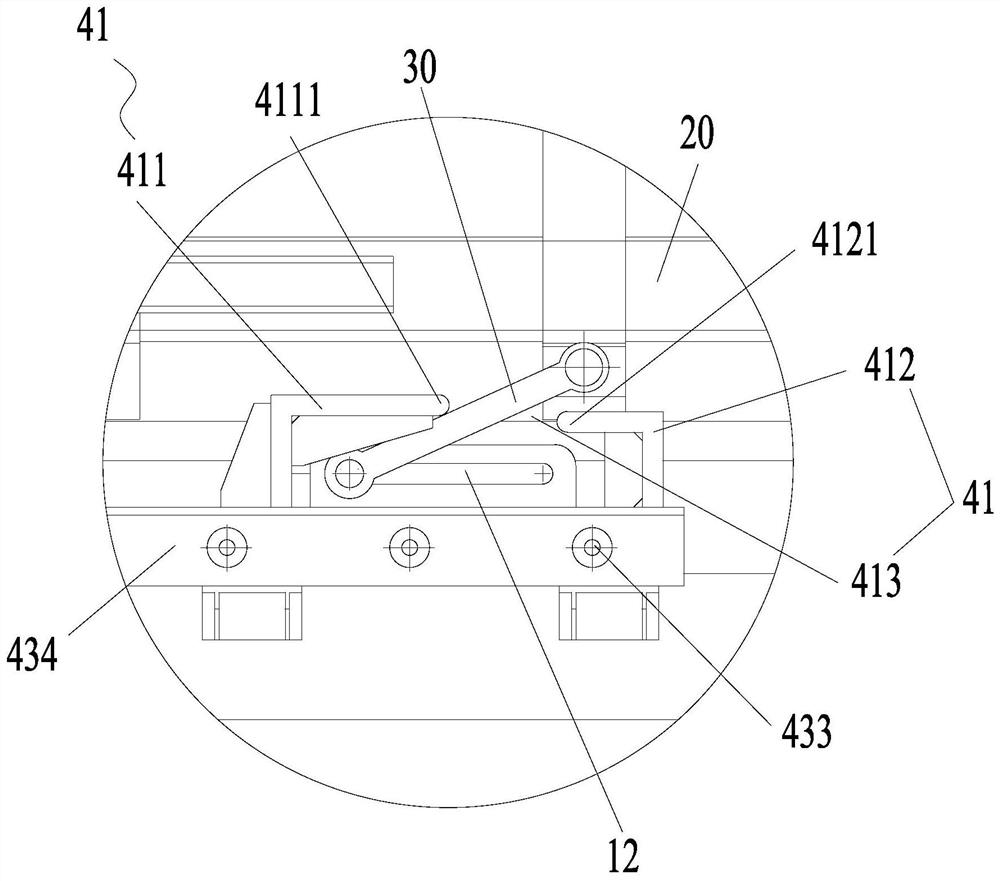

Railway freight shed car roof system

ActiveCN114104025AReduce complexitySimple structureRailway transportSliding roofsRail freight transportStructural engineering

The invention discloses a railway freight shed car top cover system which comprises a top cover arranged at the top of a car body and end plates in sealing contact with the front end and the rear end of the top cover, the top cover comprises a fixed cover plate with the hollow middle and two movable cover plates arranged in the middle of the fixed cover plate, and transmission systems are independently arranged on the two movable cover plates; each transmission system comprises a driving structure arranged in the vehicle body, a transmission structure connected with the output end of the driving structure and a connecting rod structure connected with the output end of the transmission structure, and the connecting rod structure is connected with the bottom of the movable cover plate on the same side; the driving structure is used for driving the transmission structure to enable the two movable cover plates to laterally slide in opposite directions through the connecting rod structure so as to open the top cover. According to the invention, the movable cover plate is divided into two parts and is designed into a split sideslip type, the two symmetrical movable cover plates are respectively controlled by two sets of same and independent transmission systems, and the two sets of transmission systems are independent and do not interfere with each other, so that the complexity of a mechanical structure and a transmission mechanism is reduced.

Owner:CRRC YANGTZE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com