Multipurpose railway boxcar with flatcar function

A railway boxcar, multi-purpose technology, applied in the direction of railway car body, railway car body parts, railway transportation, etc., can solve the problems of increasing the ineffective consumption of empty return journeys, reducing the efficiency of railway transportation, and increasing idle time, so as to improve transportation efficiency. and transportation economy, reducing ineffective energy consumption, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a multi-purpose railway huisher with a flat car function.

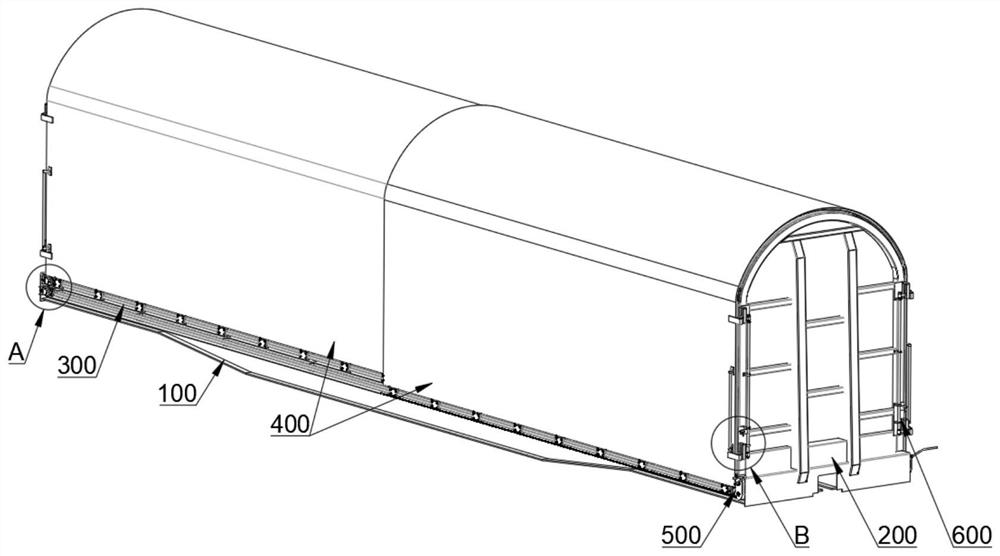

[0048] Such as Figure 1 ~ 10 As shown, the multi-purpose railway hut includes a flat vehicle body 100, two end wall composition 200, two pairs of shangbody guide rails 300, two active shacks 400, shangting transmission 500, and shangzid locking device 600.

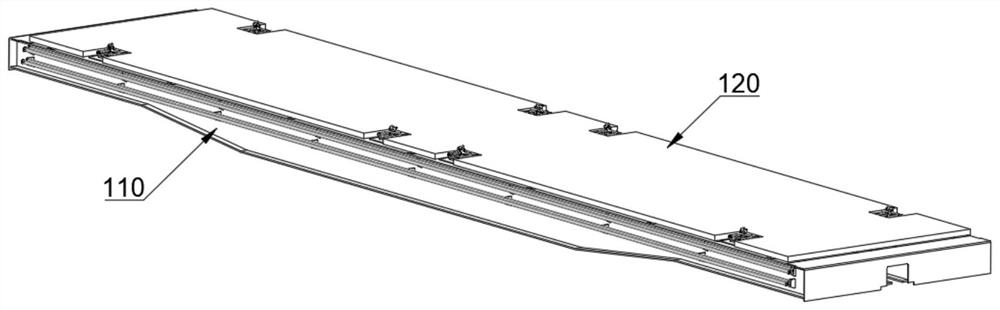

[0049] Such as figure 2 As shown, the flat vehicle body 100 includes a chassis 110 and a floor 120 that is laid on the chassis 110. The shangbody rail 300 is a inert-like light rail (see GB / T 11264-2012 hot rolled light rail), and is fixed to the outside of the chassis 110 through its bottom lateral direction.

[0050] The two pairs of shangbody rails 300 are arranged in parallel, respectively correspond to one active shack 400, respectively. Each pair is provided on both sides of the chassis 110 of the flat vehicle body 100, respectively, and can carry a movable shack 400 slider thereon.

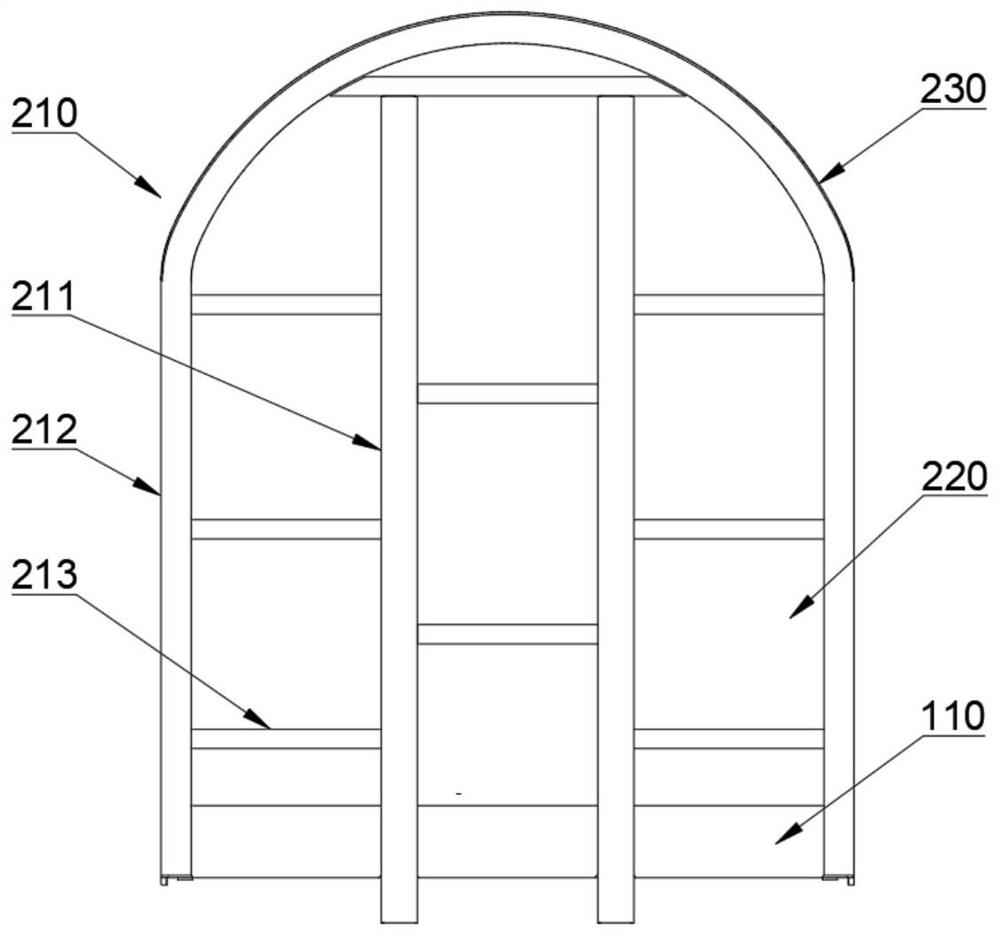

[0051] Such as image 3 As shown, the end ...

Embodiment 2

[0073] This embodiment provides a specific structure in Example 1 in the shalar lock device 600.

[0074] Such as Figure 12 ~ 17 As shown, the shangzid lock device includes a mounting seat 610, a mount 620, a down mount 630, a push rod 640, two latch 650, and a socket 660. among them:

[0075] The mount 610 is mounted, and the mounting seat 630 is provided with the pin guide guide 780 and the push rod guide ear 670, and the mounting seat 630 is also provided with a locking plate 631 and a tank mounting plate 633, see Figure 13 ~ 14 .

[0076] The pin guide holder 680 is used to guide the pin 650 so that the latch 650 can only be moved up and down, and cannot be rotated in the push rod 640. The latch guide 680 is provided with a cross section of a cross-sectional guide groove 681, the guiding groove 681 is parallel to the mounting seat and penetrates the slot 680, the longitudinal groove of the guide groove 681 and the mounting seat vertical and does not penetrate the socket guide 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com