Railcar Cover Systems

a technology for rail cars and covers, applied in brake systems, transportation and packaging, railway components, etc., can solve the problems of reducing the effective payload of rail cars, reducing the cargo load the user can haul, and not being able to arrange a suitable method for removal and replacement of covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

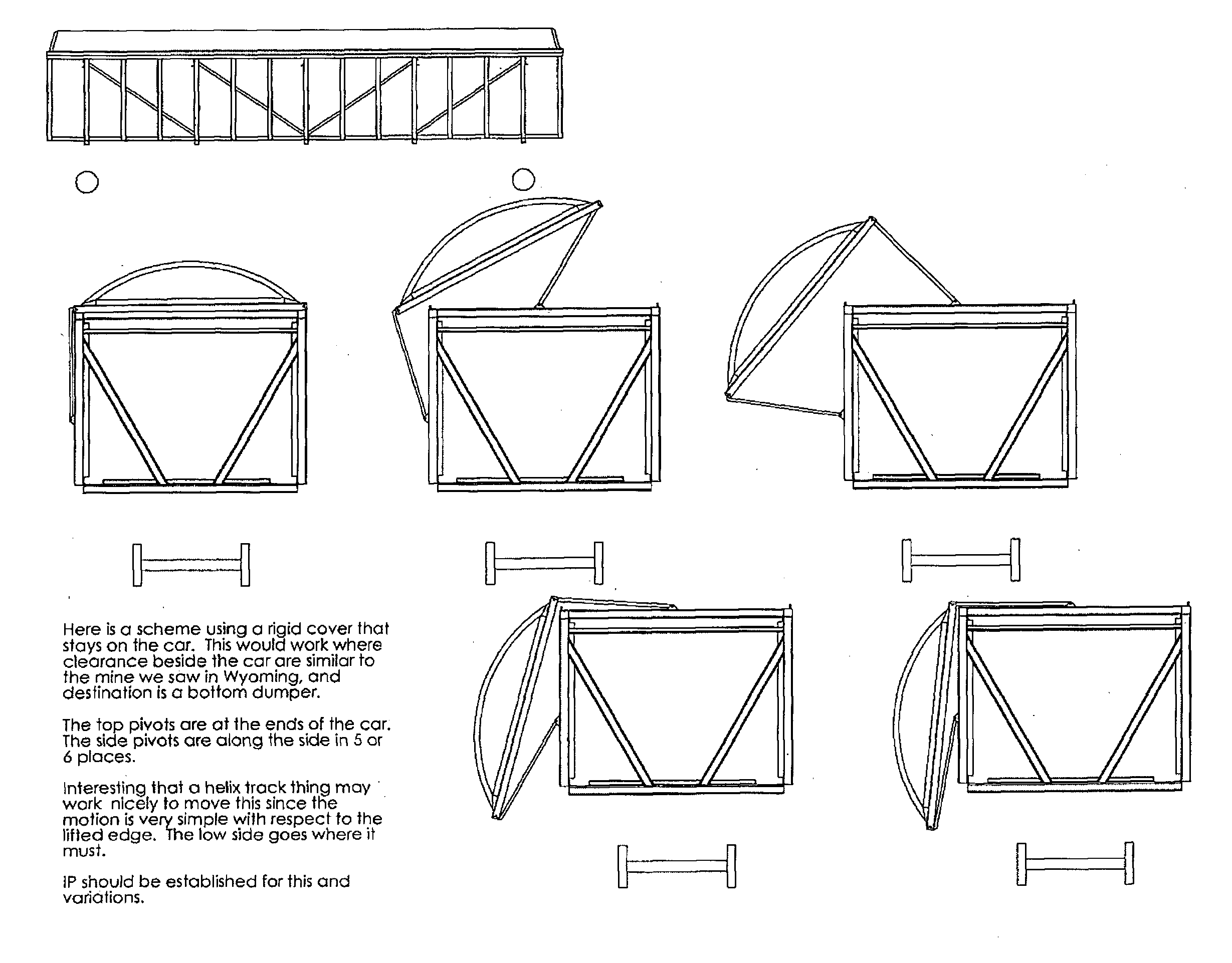

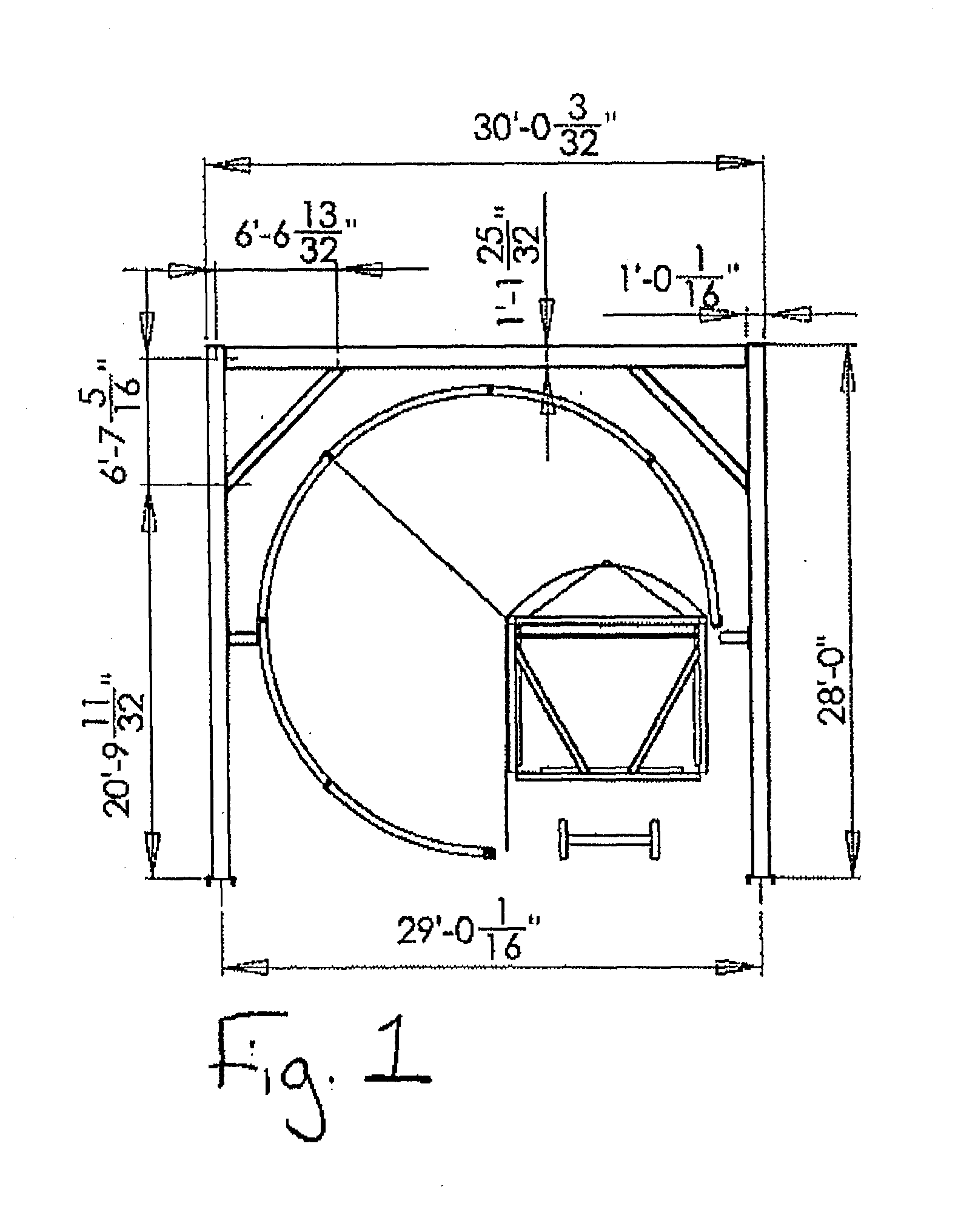

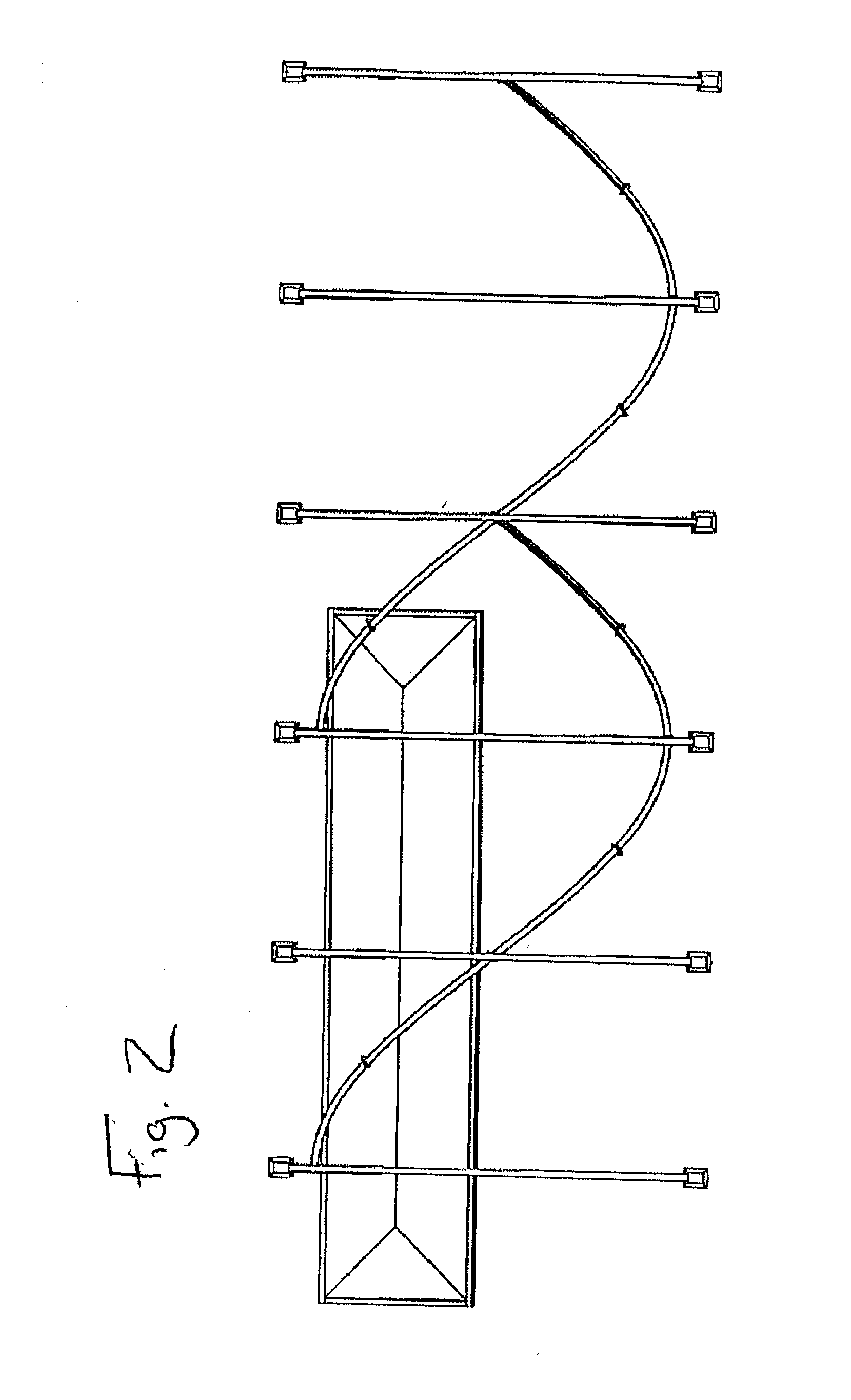

[0028]The present invention comprises a system for removal and replacement of top-loading open top rail car covers. According to one embodiment of the present invention, there is provided a semi-automatic or fully automatic system for continuous serial handling of rigid or self supporting rail car covers for gondola rail cars. Preferably, a continuous method is used to ensure use of covered rail cars does not interfere with methods of car loading or unloading for continuously moving trains.

[0029]According to another embodiment of the present invention, similar technology may also be used for situations in which train motion is intermittent at loading or unloading locations, but is part of a continuous industrial process. Use of an intermittent method ensures that use of covered cars does not interfere with methods of car loading or unloading for intermittently moving trains.

[0030]According to an embodiment of the system of the present invention, there is provided cover means for an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com