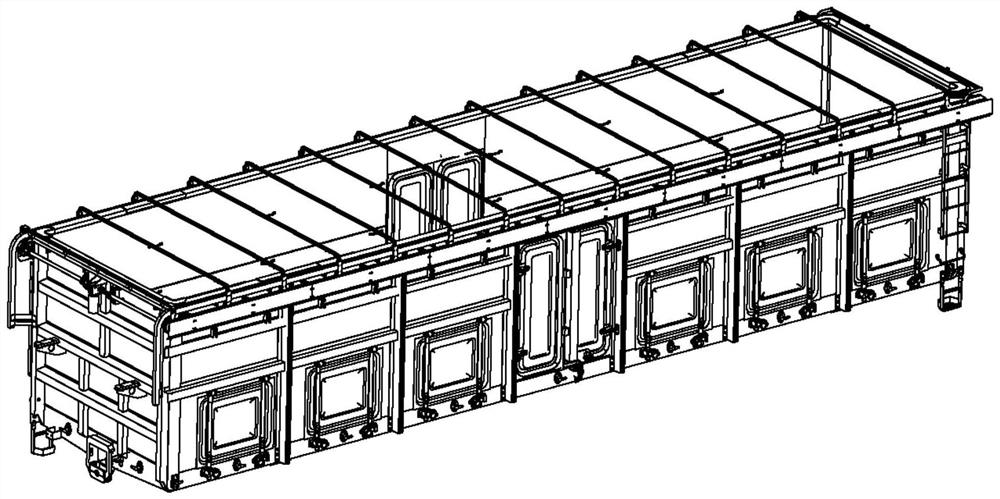

Longitudinal telescopic railway wagon top cover

A railway freight car, telescopic technology, applied in the direction of railway roof, railway car body parts, sliding roof, etc., can solve the problems of affecting unloading, shortening service life, poor versatility, etc., to achieve convenient operation, light weight, maintenance and maintenance. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0048] In conjunction with the accompanying drawings.

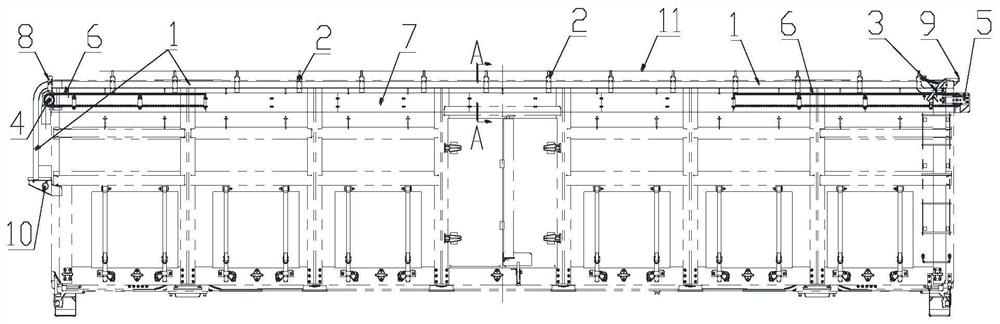

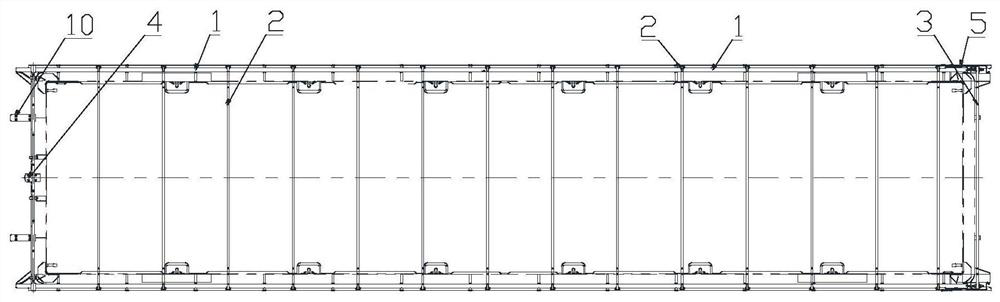

[0049] The movable roof device of the present invention is mainly composed of track 1, driven slider and shed pole 2, active slider and shed pole 3, transmission shaft 4, tension wheel 5, chain and bracket 6. The chain baffle is composed of 7. The tail slider and the shed pole are composed of 8. The shed pole support is composed of one 9. The shed pole support is composed of two 10 and tarpaulin 11.

[0050] Track composition 1 is mainly composed of track 1.1, track support 1.2, sealing plate 1.3, locking plate 1.4 and so on. The track 1.1 adopts a C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com