Slidable cover assembly for merchandise carrying vehicle platforms

a technology for merchandise and vehicle platforms, which is applied to roofs, sliding roofs, railway roofs, etc., can solve the problems of time-consuming and expensive, large and difficult installation of covers, and relatively short life of such assemblies, and achieves the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

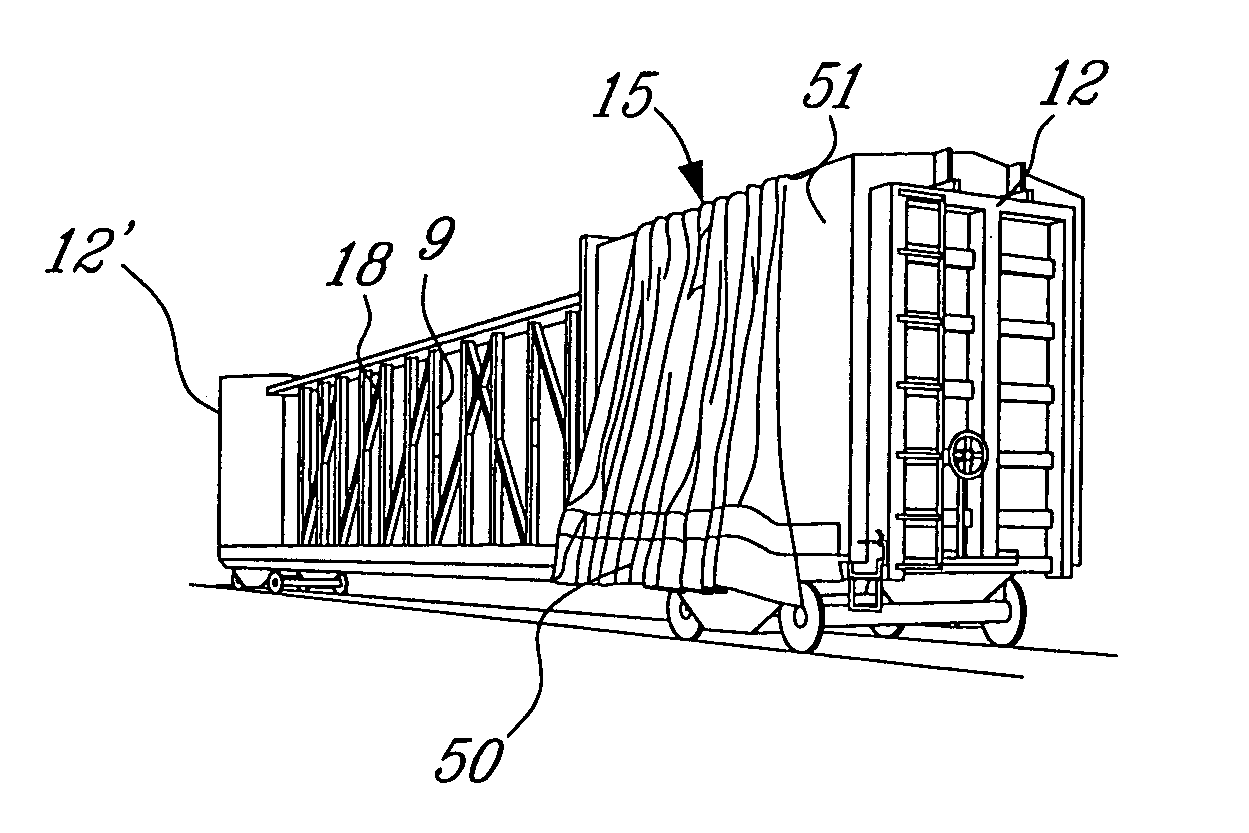

[0030] Referring now to the drawings, and more particularly to FIG. 1, there is shown generally at 10 the slidable cover assembly of the present invention and secured to a railway vehicle merchandise carrying platform 11. As hereinshown, the platform 11 is provided with opposed bulk heads 12 and 12′ and an extendable tarp 13 supported by frame members, as will be described later, which spans the cargo area 9 of the railway platform between the bulk heads 12 and 12′. The tarp is secured to the railway platform at a lower end thereof by tie-down straps 14 provided at spaced apart intervals on opposed sides of the assembly.

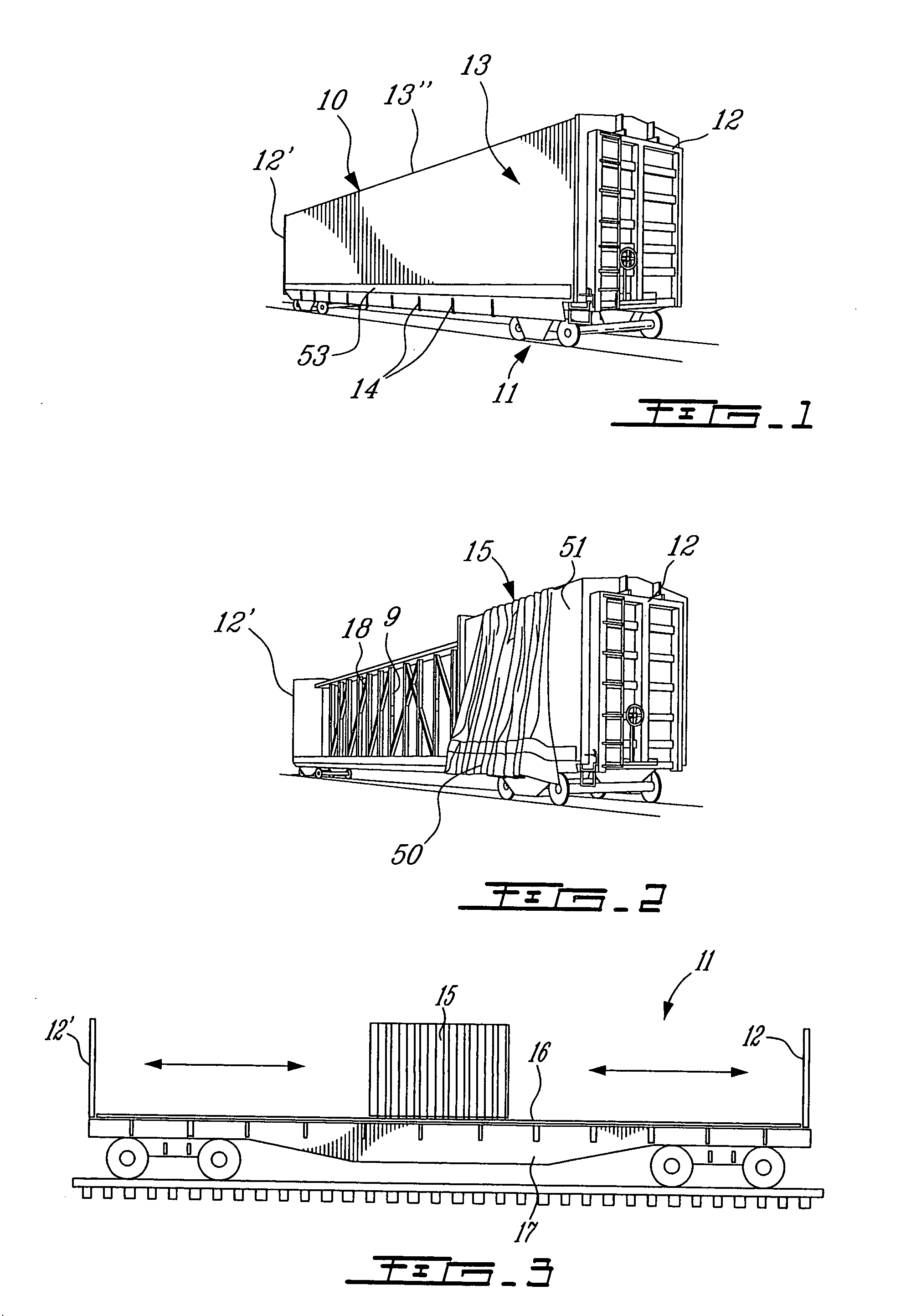

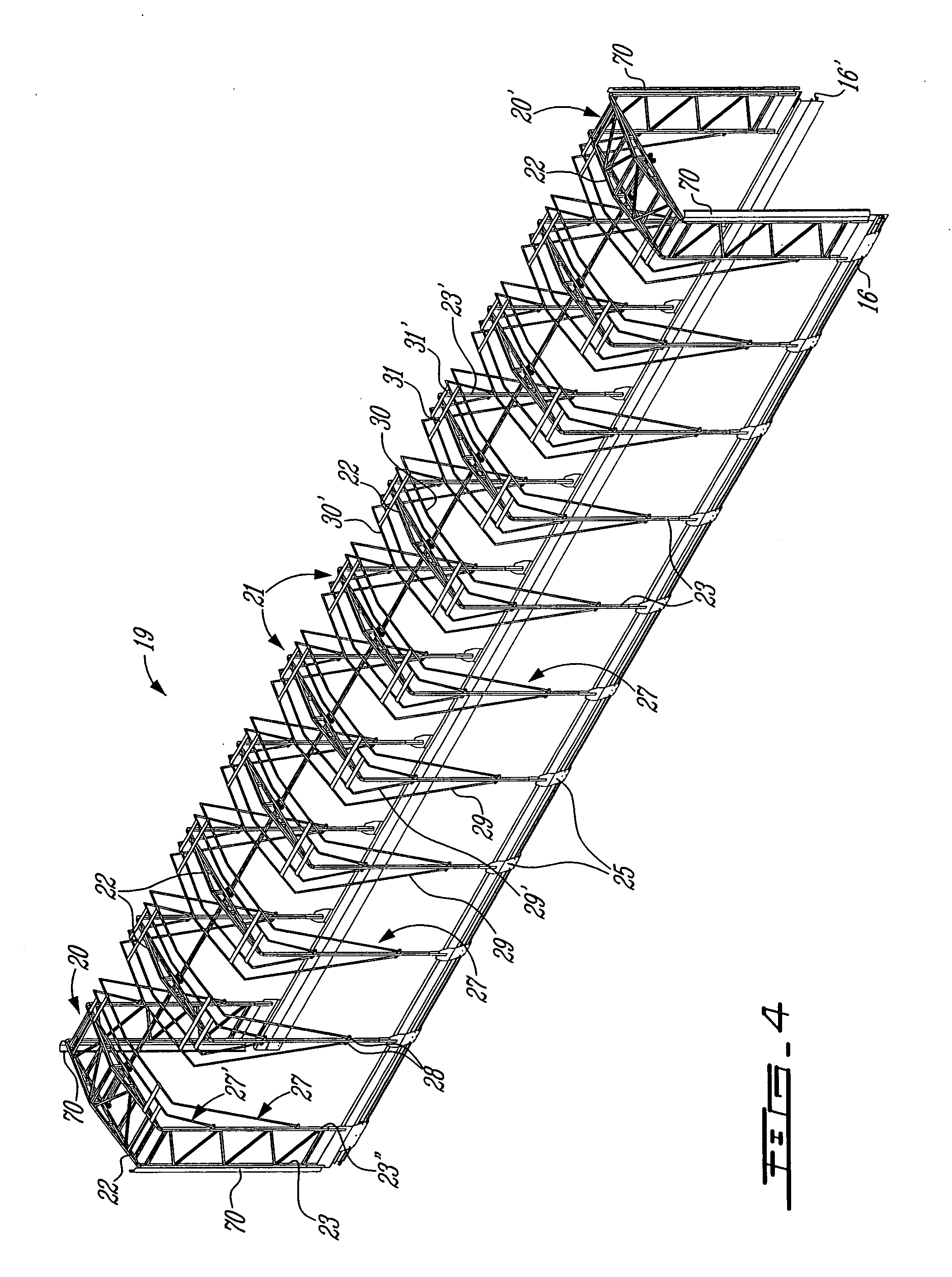

[0031]FIGS. 2 and 3 illustrate the slidable cover assembly in its retracted collapsed condition to form a displaceable collapsed package 15 which is movable along opposed rails 16 secured to the platform frame 17 on opposed sides thereof. Therefore, by displacing the collapsed package along these rails, the entire inner cargo area 9 of the platform can be exposed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com