Tarpaulin structure

A waterproof cover and sub-structure technology, applied to the roof, transportation and packaging, railway car body parts, etc., can solve the problem that common unlocking cannot be completed by one operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

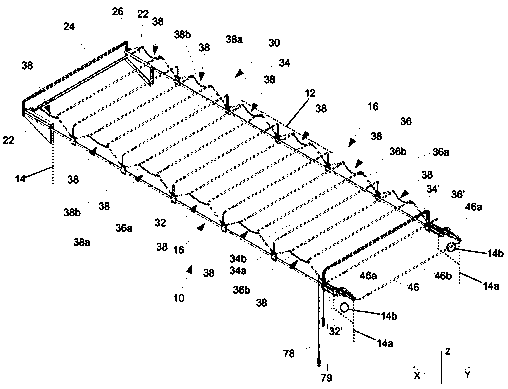

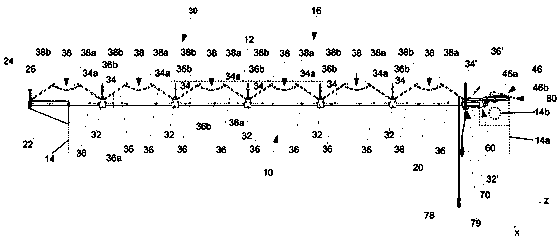

[0167] exist figure 1 and figure 2 , shows a side view from the waterproof cover structure 10 or a perspective view from the side, wherein the waterproof cover 12 is represented by a dotted line; for ease of presentation, the waterproof cover is not represented in other figures. Furthermore, dashed lines are used to indicate the outline portion of the container 14 on which the collapsible top frame 16 is disposed. The container 14 is designed, for example, as a dump chute in which debris but also dust-generating material can be contained and thus advantageously needs to be covered by the waterproof cover structure 10 in some cases even when transported on a truck. The front end wall 14a of the container 14 is designed as a slot cover which is connected to the container 14 by means of a pivot joint 14b and which can be emptied by tipping over.

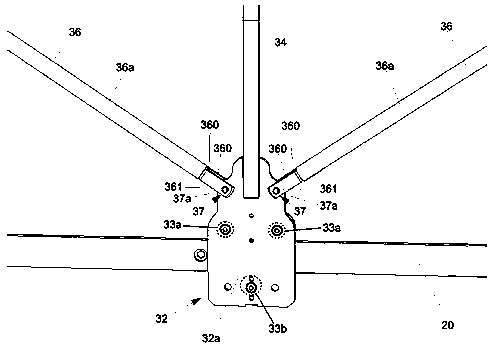

[0168] On both sides of the container 14, on its outer wall, the waterproof cover structure 10 has a connected guide rail 20 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com