Sliding top cover of railway maneuvering equipment vehicle

A technology for equipment and mobility, which is applied in the direction of sliding roofs, railway roofs, railway car body parts, etc., can solve problems such as increased failures, cumbersome installation, and complex transmission structures, so as to prevent uncontrollable sliding and reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

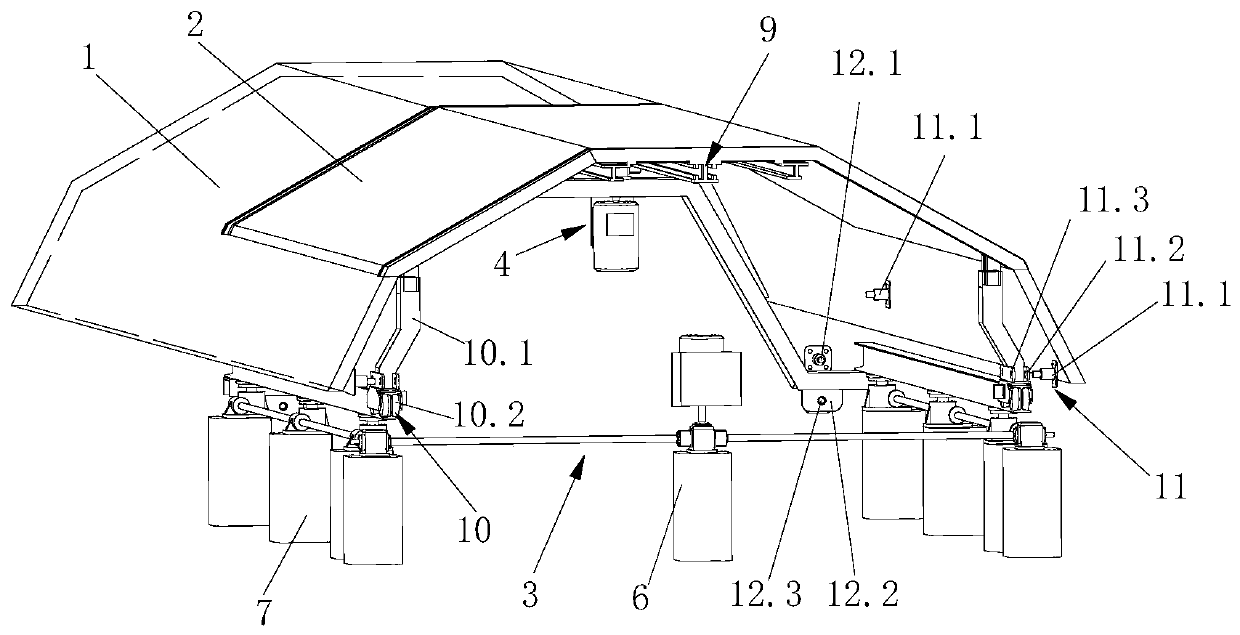

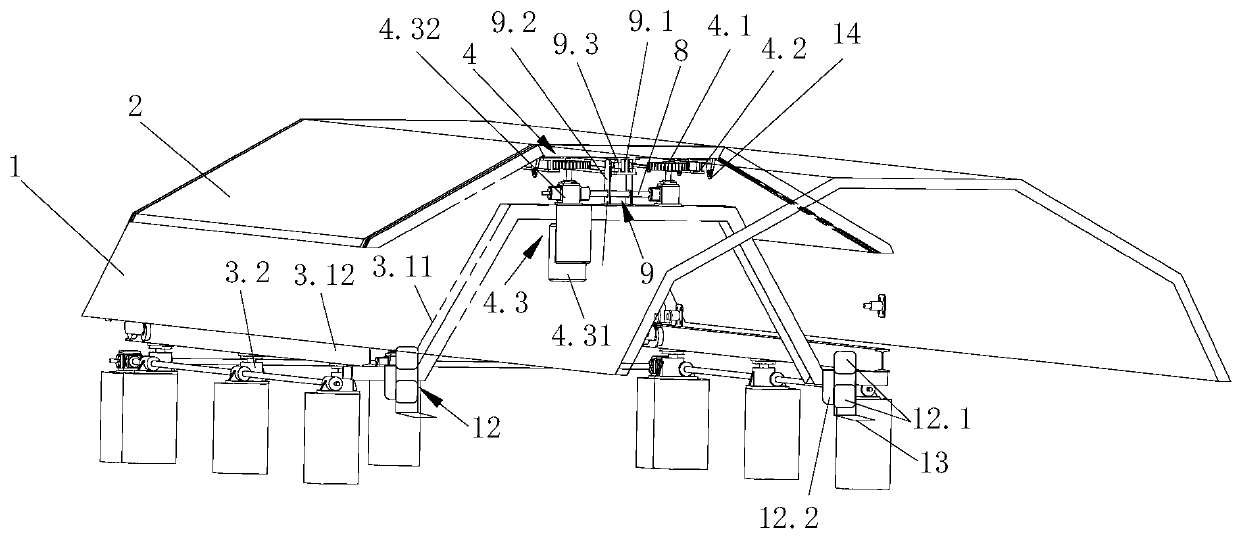

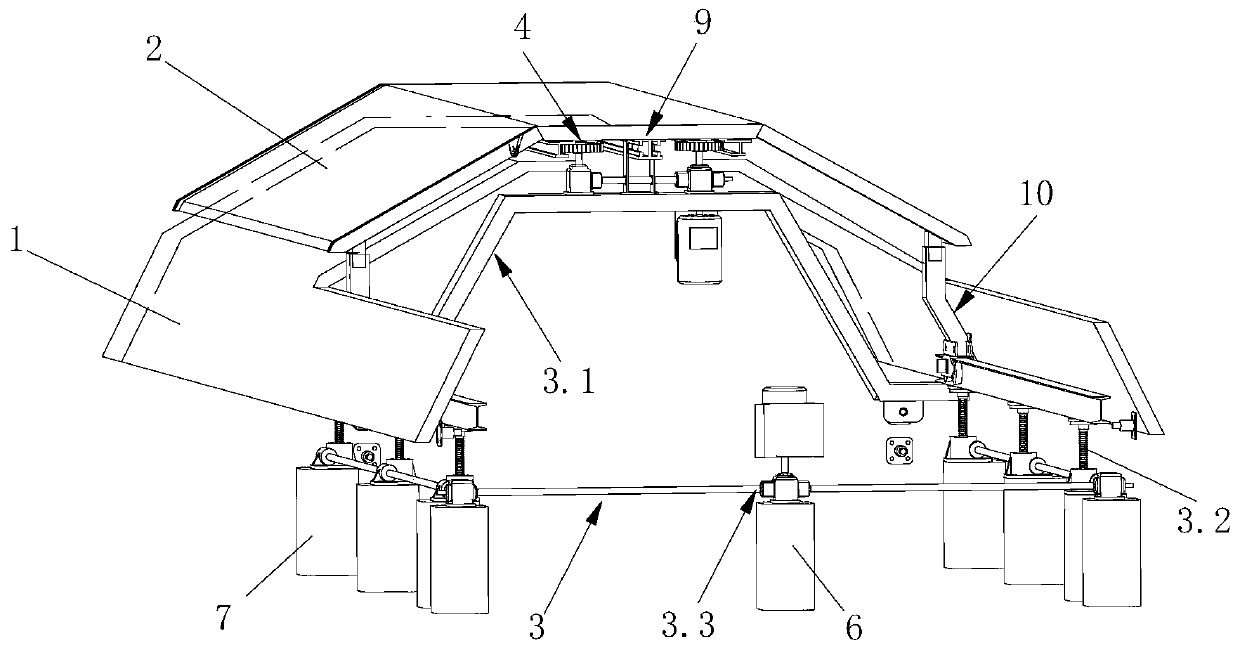

[0034] Such as Figure 1~3 The sliding top cover of a railway mobile equipment vehicle shown is characterized in that it includes a fixed cover body 1 and a movable cover body 2, and the lower part of the movable cover body 2 is provided for driving it to move up and down and forward and backward relative to the fixed cover body 1. The lifting mechanism 3 and the sliding mechanism 4; the lifting mechanism 3 includes a support frame 3.1, and several lifts 3.2 and a first drive mechanism 3.3 for driving the lift 3.2 to lift are arranged below the support frame 3.1; the sliding mechanism 4 It includes several gears 4.1, several racks 4.2 arranged in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com