Telescopic pipe type bullet supply guide mechanism and method

A telescopic tube and ammunition feeding technology, which is applied in the field of firearms, can solve problems such as limited adjustment range, top bomb failure, and non-existence of ammunition feeding, and achieve a smooth feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] In this embodiment, the gun barrel is used as the front end.

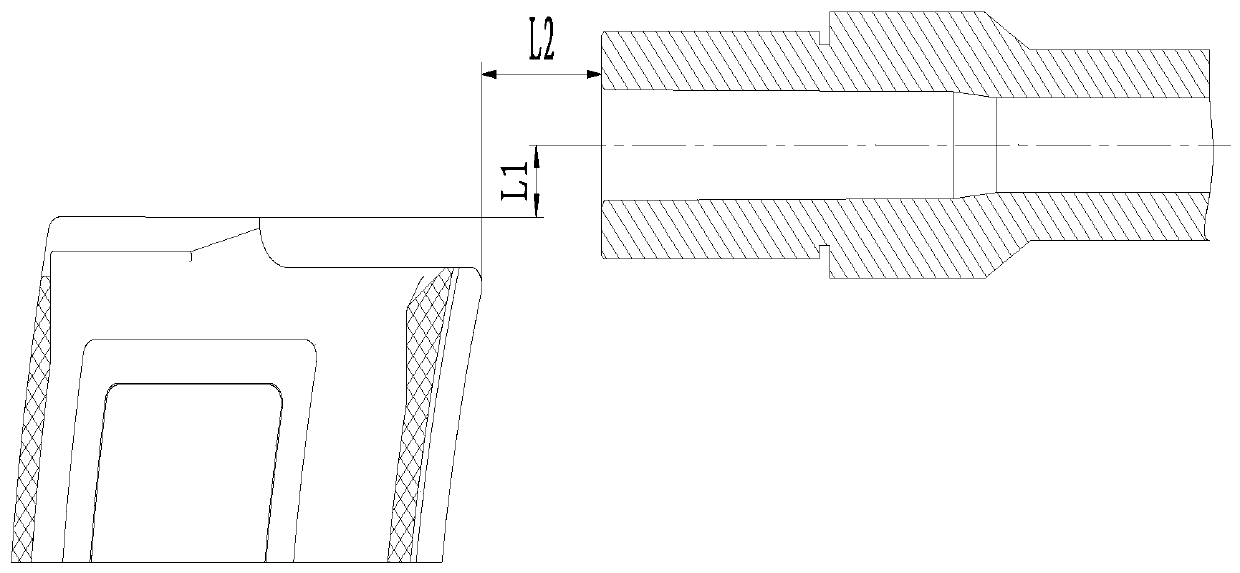

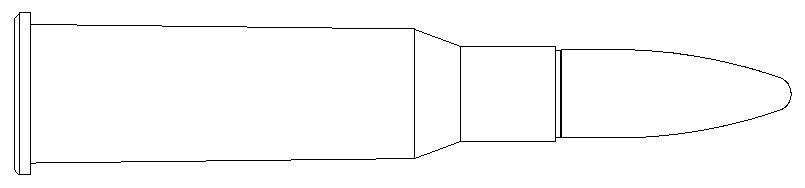

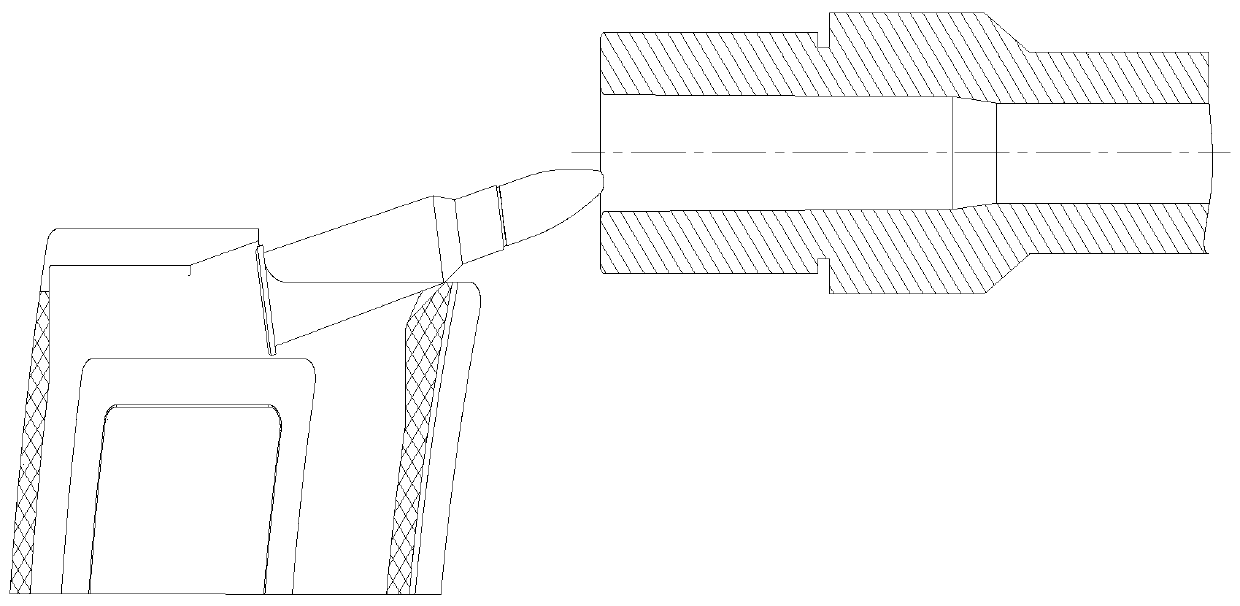

[0033] Such as Figure 6 A telescopic tube type feeding guide mechanism shown is installed at the tail end of the barrel part, and the bomb feeding guide mechanism includes a guide tube 4 and a guide pipe spring 8, and the gun barrel part includes an outer gun barrel 9 and the bullet chamber 6 fixedly installed in the outer gun barrel 9, the middle part of the bullet chamber 6 is provided with a limit surface 11, and the tail is provided with a bullet chamber inlet guide slope 5 for regularizing bullets, and the guide tube 4 and the guide pipe spring 8 are all sleeved on the outer peripheral surface of the chamber 6, and the guide pipe 4 is arranged at the tail of the chamber 6, and the end of the guide pipe 4 away from the chamber 6 is trumpet-shaped, forming a guide Tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com