Production process for separating and recycling paper-plastic composites

A separation, recovery and production process technology, applied in the field of waste material recycling, can solve the problems of environmental pollution, low recycling rate, waste of energy and water resources, etc., and achieve the effect of saving water resources, high recovery rate, and complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

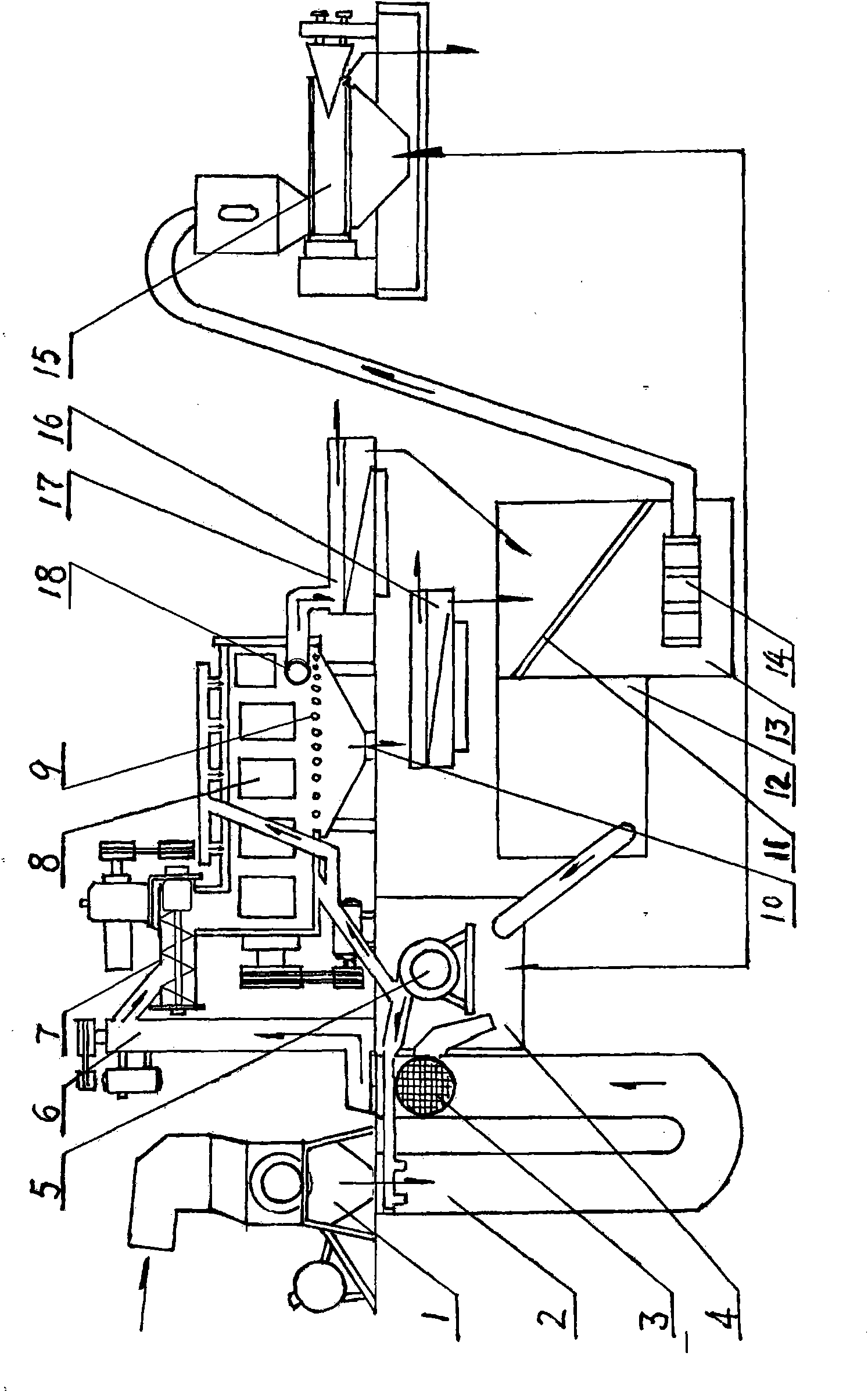

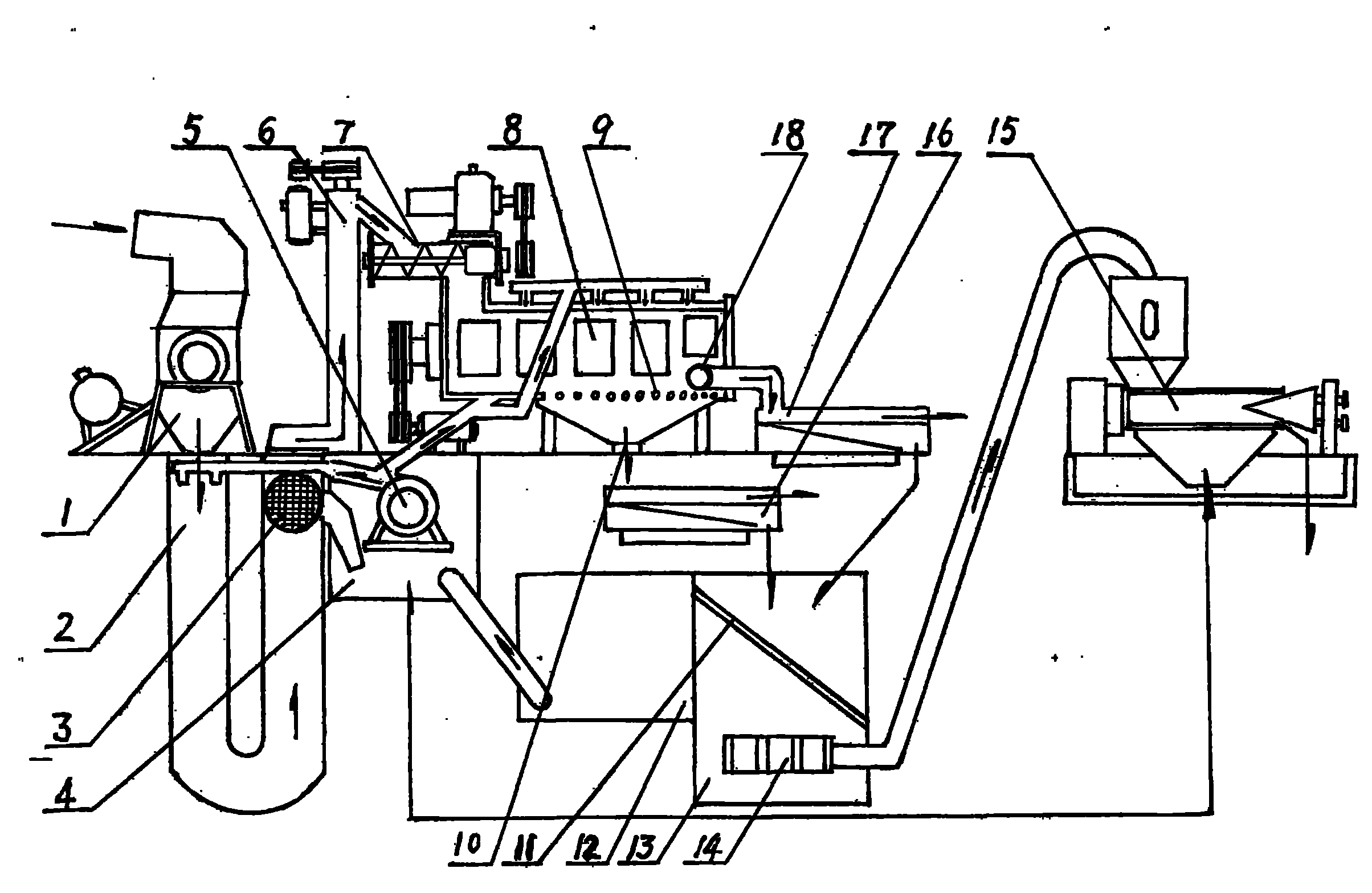

[0018] Such as figure 1 As shown, a production process for the separation and recovery of paper-plastic composites:

[0019] The paper-plastic composite material is crushed in the crusher 1 (750 crusher with water can be selected, and the spiral crusher with water can be used for dirty materials). Generally, the length is less than 20 cm, and during the crushing process Cleaning the material, after cleaning, the material enters the immersion cleaning tank 2, and the material is wet-decomposed in the soaking cleaning tank 2, and at the same time, it is cleaned again, and the wet-decomposed material is convenient for the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com