Environment-friendly degradable plant solid glue stick and preparation method thereof

A solid glue stick, plant technology, applied in the direction of glue sticks, adhesives, N-vinylpyrrolidone copolymer adhesives, etc., can solve the problems of lower K value, lower viscosity, lower environmental performance, etc., and achieve drying speed. The effect of fast, low production cost and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

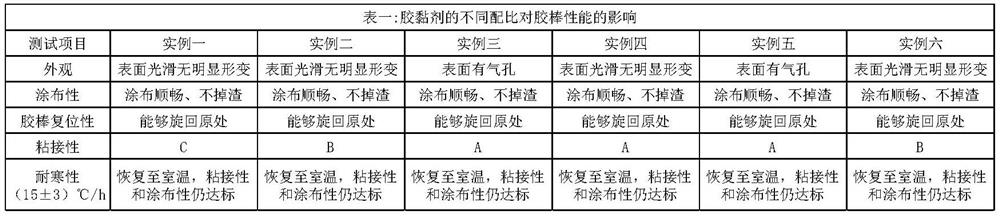

Examples

Embodiment 1

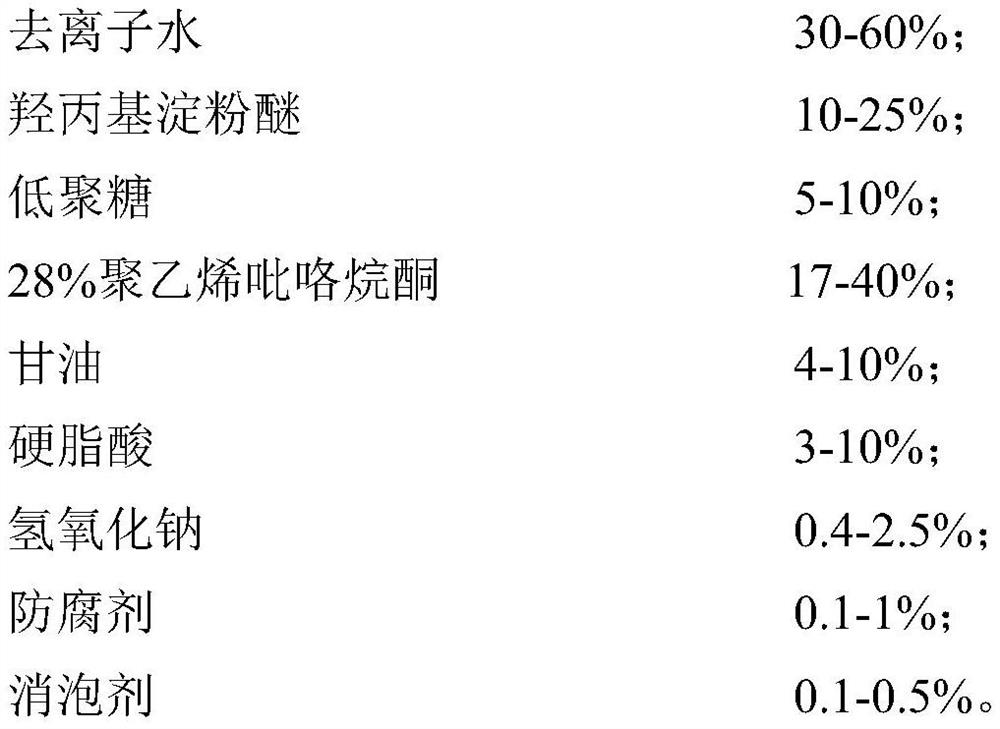

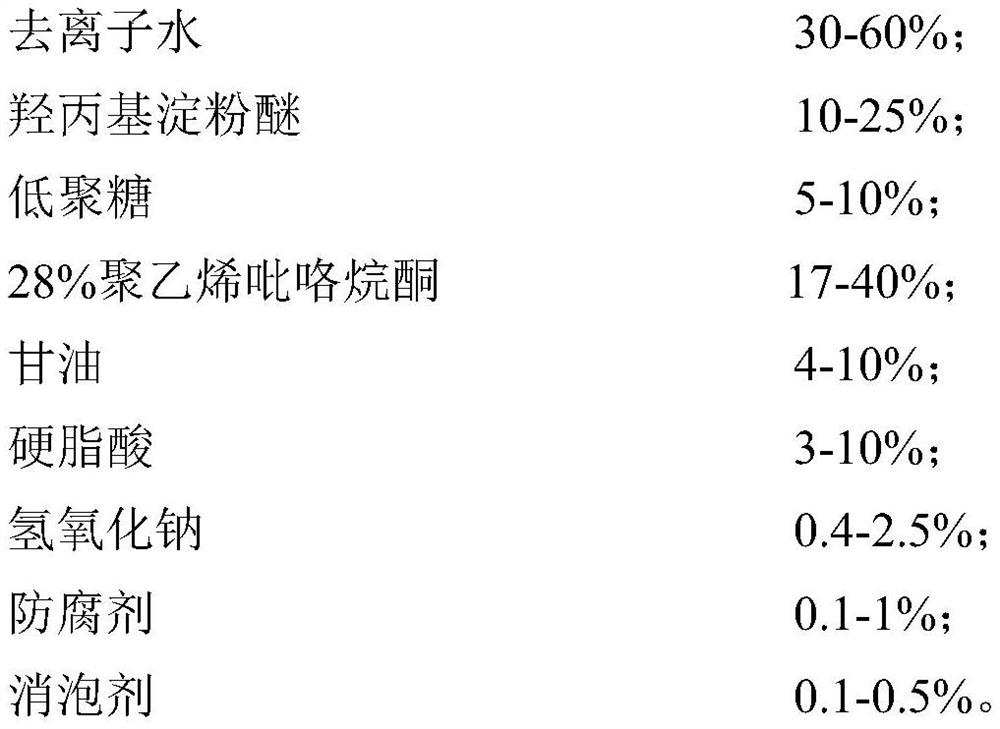

[0028] The environmentally friendly and degradable plant solid glue stick of the present embodiment is prepared from the raw materials of the following percentages:

[0029] Glycerin 5%, 28% K90 polyvinylpyrrolidone 30%, hydroxypropyl starch ether 10%, oligosaccharides 5%, stearic acid 6%, sodium hydroxide 0.9%, preservative sodium butylparaben 0.05% , preservative IPBC 0.125%, defoamer 0.1%, the rest is deionized water, the sum of the above-mentioned components is 100%.

[0030] The preparation method of the above-mentioned environmentally friendly degradable plant solid glue is as follows:

[0031] Add deionized water, glycerin, and 28% polyvinylpyrrolidone solution into the reaction kettle at room temperature, stir and mix evenly, and the stirring speed is 300-350rpm / min; add oligosaccharides into the reaction kettle, stir for 10-30min to disperse and dissolve In the solution; then slowly add hydroxypropyl starch ether to make it evenly dispersed, then heat up to about 85°...

Embodiment 2

[0033] The environmentally friendly and degradable plant solid glue stick of the present embodiment is prepared from the raw materials of the following percentages:

[0034] Glycerin 5%, 28% K90 polyvinylpyrrolidone 30%, hydroxypropyl starch ether 15%, oligosaccharides 5%, stearic acid 6%, sodium hydroxide 0.9%, preservative sodium butylparaben 0.05% , preservative IPBC 0.125%, defoamer 0.1%, the rest is deionized water, the sum of the above-mentioned components is 100%.

[0035] The preparation method of the above-mentioned environmentally friendly degradable plant solid glue is as follows:

[0036] Add deionized water, glycerin, and 28% polyvinylpyrrolidone solution into the reaction kettle at room temperature, stir and mix evenly, and the stirring speed is 300-350rpm / min; add oligosaccharides into the reaction kettle, stir for 10-30min to disperse and dissolve In the solution; then slowly add hydroxypropyl starch ether to make it evenly dispersed, then heat up to about 85°...

Embodiment 3

[0038] The environmentally friendly and degradable plant solid glue stick of the present embodiment is prepared from the raw materials of the following percentages:

[0039] Glycerin 5%, 28% K90 polyvinylpyrrolidone 30%, hydroxypropyl starch ether 20%, oligosaccharides 5%, stearic acid 6%, sodium hydroxide 0.9%, preservative sodium butylparaben 0.05% , preservative IPBC 0.125%, defoamer 0.1%, the rest is deionized water, the sum of the above-mentioned components is 100%.

[0040] The preparation method of the above-mentioned environmentally friendly degradable plant solid glue is as follows:

[0041] Add deionized water, glycerin, and 28% polyvinylpyrrolidone solution into the reaction kettle at room temperature, stir and mix evenly, and the stirring speed is 300-350rpm / min; add oligosaccharides into the reaction kettle, stir for 10-30min to disperse and dissolve In the solution; then slowly add hydroxypropyl starch ether to make it evenly dispersed, then heat up to about 85°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com