Emulsion pressure-sensitive adhesive for protecting adhesive tape and preparation method thereof

A protective tape and hydraulic technology, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc., can solve the problems of low peel strength and initial adhesion, poor high temperature and high humidity aging resistance, high temperature and high humidity Poor aging performance and other problems, to achieve good high temperature and high humidity aging performance, strong initial adhesion, high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

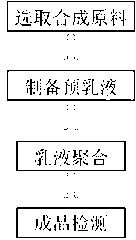

[0020] The specific preparation method is as follows:

[0021] a) Select synthetic raw materials. The raw materials used for the emulsion pressure-sensitive adhesive used to protect the tape include: butyl acrylate, isooctyl acrylate, methyl methacrylate, styrene, acrylic acid, hydroxypropyl acrylate, initiator, buffer agent and emulsifier; the mass ratio of each component is: butyl acrylate 41%, isooctyl acrylate 41%, methyl methacrylate 5%, styrene 5%, acrylic acid 1.6%, hydroxypropyl acrylate 5%, Initiator 0.6%, buffer 0.3%, emulsifier 0.5%. Among them, butyl acrylate and isooctyl acrylate are soft monomers with low glass transition temperature, which endow the adhesive with bonding performance; methyl methacrylate and styrene are hard monomers with high glass transition temperature, and after copolymerization with soft monomers Produce better cohesive strength; acrylic acid and hydroxypropyl acrylate are functional monomers, which can impart reactivity, hydrophilicity, wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com