Heat-conducting photoresist and application thereof

A technology of photoresist and thermally conductive filler, which is applied in the direction of photosensitive materials used in optomechanical equipment, etc., and can solve the problems of inability to transfer heat, thermally conductive packaging glue, and non-thermal conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

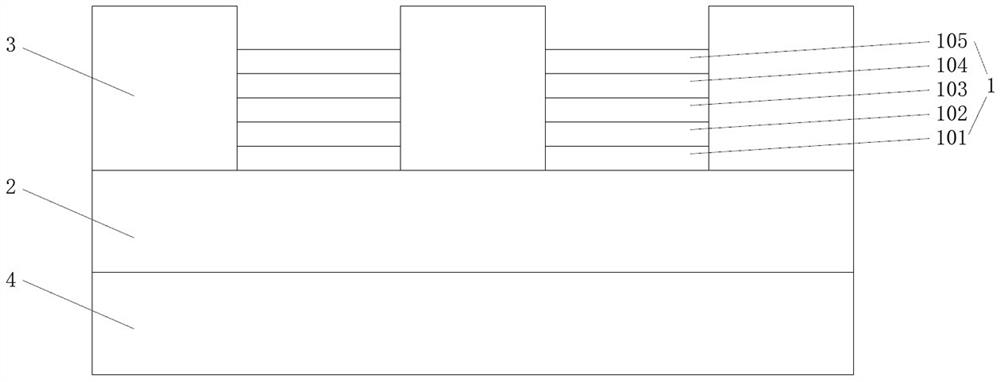

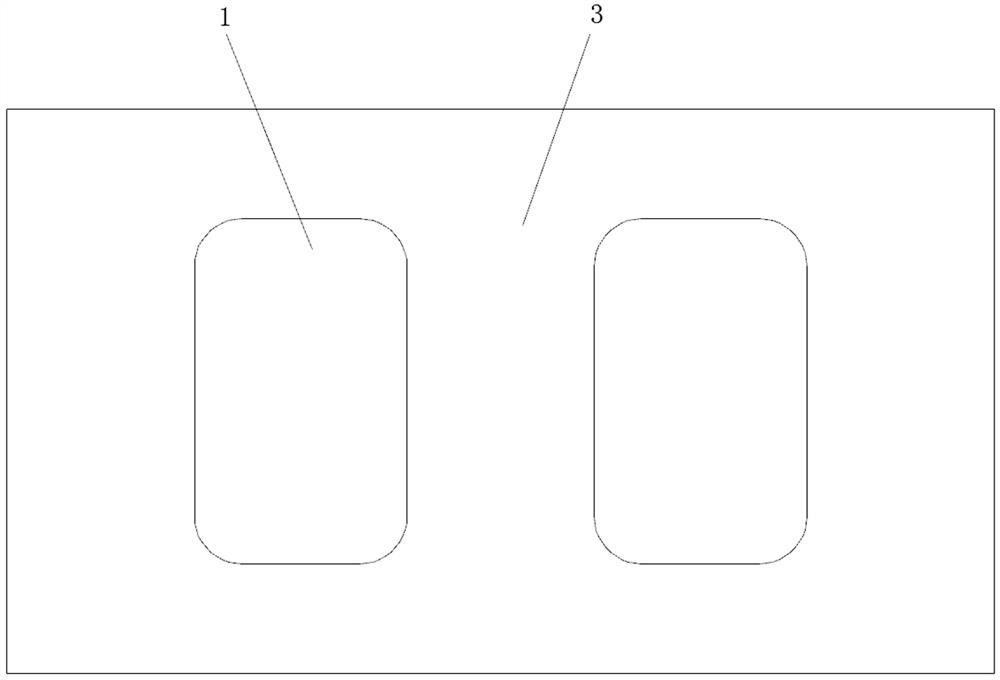

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] The invention provides a heat-conducting photoresist, which is formed by adding sub-micron-level heat-conducting fillers to the common UV-sensitive resin photoresist. The thermally conductive filler does not need to be pretreated, and can be directly mixed with the resin photoresist according to a set mass ratio and vigorously stirred and evenly dispersed. The thermally conductive filler has no effect on the physical and chemical properties of the photoresist.

[0022] The resin photoresist is at least one of polyvinyl laurate photoresist, ethylenic monomer photoresist and azidoquinone compound photoresist.

[0023] The thermally conductive filler is at least one of metal, metal oxide, carbon material, nitride, carbide, and silicon material. Preferably, the metal is metal powder, at least one of silver, copper or tin, preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com