Pressure-sensitive adhesive applied to PVC (polyvinyl chloride) film as well as preparation method and application of pressure-sensitive adhesive

A technology of adhesives and plasticizers, applied in the direction of film/sheet adhesives, adhesive additives, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of long-term stable use and anti-plasticizer migration Poor performance, easy to overflow glue, warping and other problems, to achieve the effect of improving anti-plasticizer migration performance, good compatibility, and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

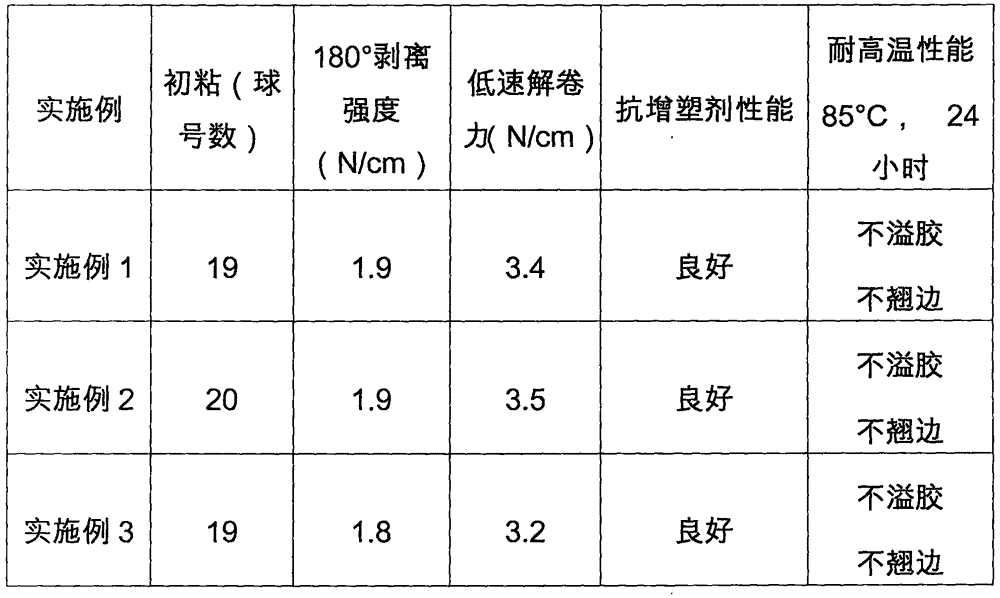

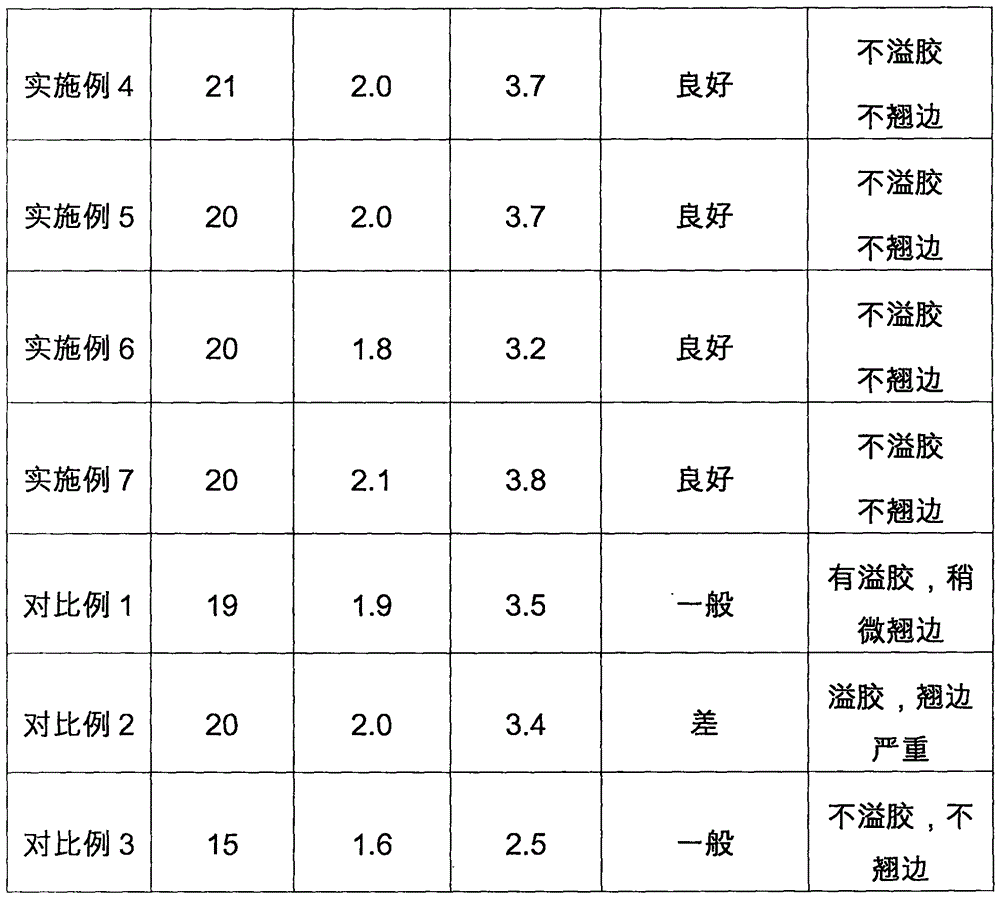

Examples

Embodiment 1

[0042]A preparation method of a rubber system hot-melt pressure-sensitive adhesive, in parts by mass, 35 parts of Quintac 3450 (SIS of star structure), 15 parts of DOP, 44 parts of Regalite R 1090, 5 parts of plastolyn 290, 1 part The antioxidant 1010 is stirred, heated, melted and mixed uniformly to obtain a rubber system hot-melt pressure-sensitive adhesive.

Embodiment 2

[0044] A preparation method of a rubber system hot-melt pressure-sensitive adhesive, in parts by mass, 35 parts of Vector 4230 (SIS of star structure), 15 parts of DOP, 44 parts of Regalite R 1090, 5 parts of plastolyn 290, 1 part Antioxidant 1010, heated, melted and mixed uniformly to obtain a rubber system hot-melt pressure-sensitive adhesive.

Embodiment 3

[0046] A preparation method of a rubber system hot-melt pressure-sensitive adhesive, in parts by mass, 35 parts of Solprene S9618 (Dynasol, star-shaped SBS), 15 parts of DOP, 44 parts of Regalite R 1090, 5 parts of plastolyn 290, 1 part of antioxidant 1010 was stirred, heated, melted and mixed uniformly to obtain a rubber system hot-melt pressure-sensitive adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com