Preparation technology for high-performance solvent copolymerization acrylate pressure-sensitive adhesive

A co-polyacrylate and solvent-based technology, which is applied in adhesive types, ester copolymer adhesives, adhesives, etc., can solve problems such as being easily affected by solvents, difficult to achieve a large enough molecular weight, and low average molecular weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

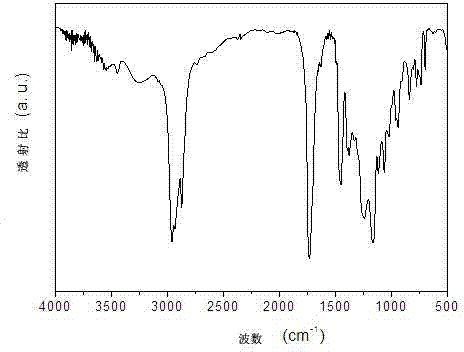

Image

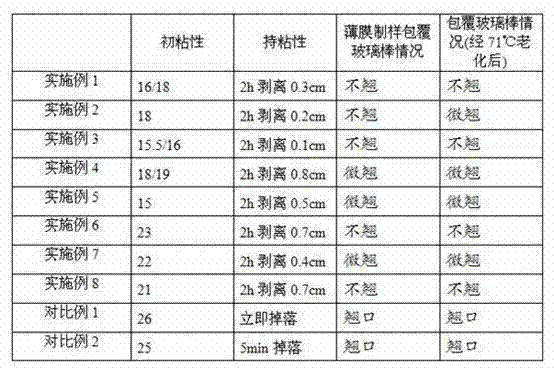

Examples

Embodiment 1

[0027] 1,200 grams of butyl acrylate, 400 g of isooctyl acrylate, 140 g of styrene, 200 g of vinyl acetate, 60 g of acrylic acid, 400 g of toluene, and 1 g of azobisisobutyronitrile were fed into a 50 L mechanically stirred reactor, and after replacing nitrogen three times, set The stirring speed is 100r / min, the temperature is raised to 82°C, the heating speed is 5°C / min, and it stabilizes to the set temperature in about 20 minutes.

[0028] After reacting at 82°C for 2.5 hours, feed 1.5 g of azobisisobutyronitrile from the solid feeding port, add 400 g of toluene from the liquid feeding port, set the stirring speed at 50 r / min, and continue the reaction for 1 hour.

[0029] Then raise the temperature to 88°C, add 1000g of ethyl acetate from the liquid feeding port, feed 1.5g of azobisisobutyronitrile from the solid feeding port, continue to react for 1 hour, then cool down, add 1200g of ethyl acetate, stir evenly from The feeding port discharges the material into the contain...

Embodiment 2

[0034] 1,000 grams of butyl acrylate, 600 g of isooctyl acrylate, 100 g of styrene, 240 g of vinyl acetate, 60 g of hydroxyethyl acrylate, 400 g of toluene, and 0.75 g of azobisisoheptanonitrile were fed into a 50L mechanically stirred reactor, and nitrogen was replaced three times After that, set the stirring speed at 100 r / min, raise the temperature to 82° C., and the heating rate is 5° C. / min. About 20 minutes to stabilize to the set temperature.

[0035] After 2.5 hours of reaction time at 76°C, feed 1 g of azobisisoheptanonitrile from the solid feeding port, add 400 g of toluene from the liquid feeding port, set the stirring speed at 50 r / min, and continue the reaction for 2 hours.

[0036] Then raise the temperature to 84°C, add 1000g of ethyl acetate from the liquid feeding port, feed 1.5g of azobisisoheptanonitrile from the solid feeding port, continue to react for 2 hours, then cool down, add 1200g of ethyl acetate, stir evenly from The feeding port discharges the ma...

Embodiment 3

[0041] 1,600 grams of butyl acrylate, 340 g of methyl methacrylate, 60 g of methacrylic acid, 400 g of chlorobenzene, and 0.75 g of azobisisoheptanonitrile were fed into a 50L mechanically stirred reactor, and after replacing the nitrogen three times, the stirring speed was set at 100r / min, the temperature was raised to 82°C, and the heating rate was 5°C / min. About 20 minutes to stabilize to the set temperature.

[0042] After 4.5 hours of reaction time at 76°C, feed 0.25 g of azobisisoheptanonitrile from the solid feeding port, add 400 g of toluene from the liquid feeding port, set the stirring speed at 50 r / min, and continue the reaction for 2 hours.

[0043] Then raise the temperature to 84°C, add 1000g of propyl acetate from the liquid feeding port, feed 1.5g of azobisisoheptanonitrile from the solid feeding port, continue to react for 2 hours, then cool down, add 1200g of propyl acetate, stir evenly from The feeding port discharges the material into the container, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com