Washable hot melt adhesive and application thereof

A hot melt adhesive, alkaline water technology, applied in the direction of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of potential threats to the environment and personal health, unstable market supply, and high prices, and achieve convenient The effect of large-scale industrial production, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

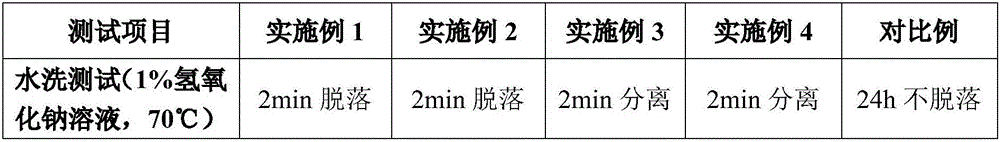

Examples

preparation example Construction

[0035] The preparation method of above-mentioned washable hot-melt adhesive comprises the following steps:

[0036] 1) Add high acid value resin, plasticizer and antioxidant into the reaction kettle, fill it with protective gas, stir and mix evenly at 120-140°C;

[0037] 2) Raise the temperature to 150-170°C, add thermoplastic polymers in batches, stir and mix evenly, vacuumize to remove air bubbles, stop heating and stirring after the whole reactant system becomes a uniform viscous liquid, and discharge the material while it is hot to obtain Washable hot melt adhesive.

Embodiment 1

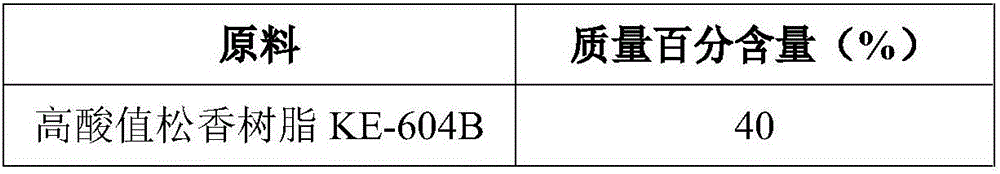

[0040] The raw material composition of a kind of washable hot-melt adhesive (pasting application pressure-sensitive adhesive) is as shown in Table 1:

[0041] Table 1 A kind of raw material composition table of washable hot melt adhesive

[0042]

[0043]

Embodiment 2

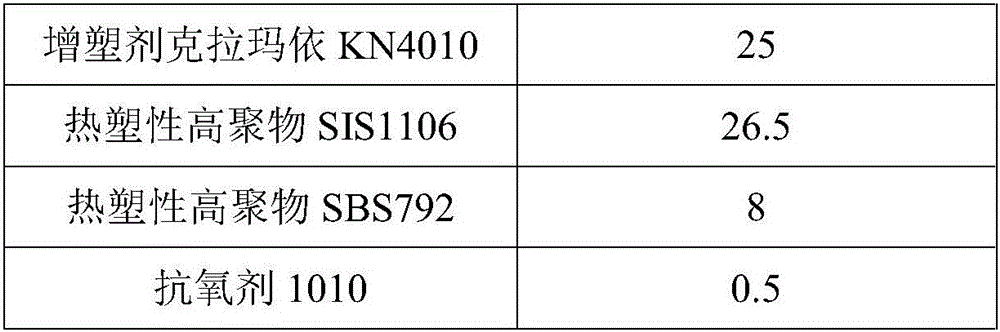

[0045] A kind of raw material composition of washable hot melt adhesive (label adhesive) is as shown in table 2:

[0046] Table 2 A kind of raw material composition table of water-washable hot-melt adhesive

[0047] raw material

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com