Foam body with thermal self-expansion function and preparation method thereof

A self-expanding, foam technology, applied in the field of fiber composite material forming, can solve the problems of adding post-repair process, poor temperature resistance of rigid foam, insufficient high-energy adhesiveness, etc. , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

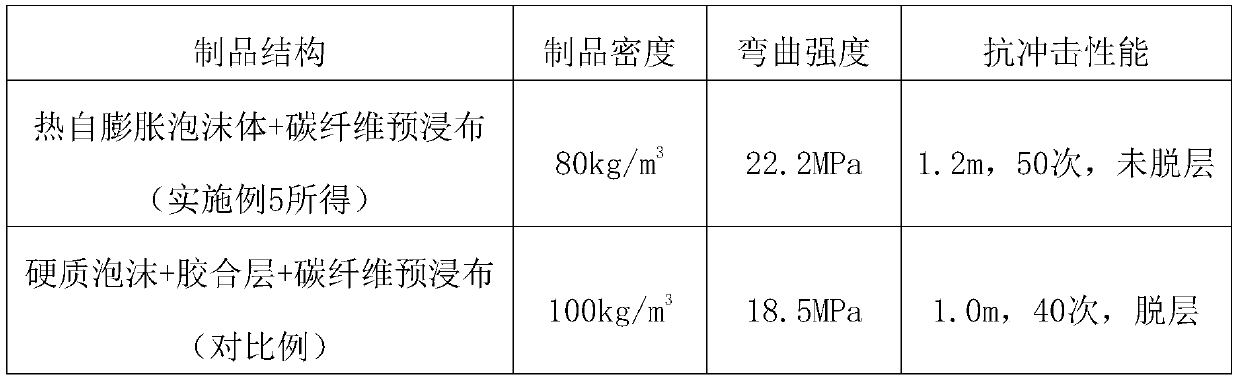

Examples

Embodiment 1

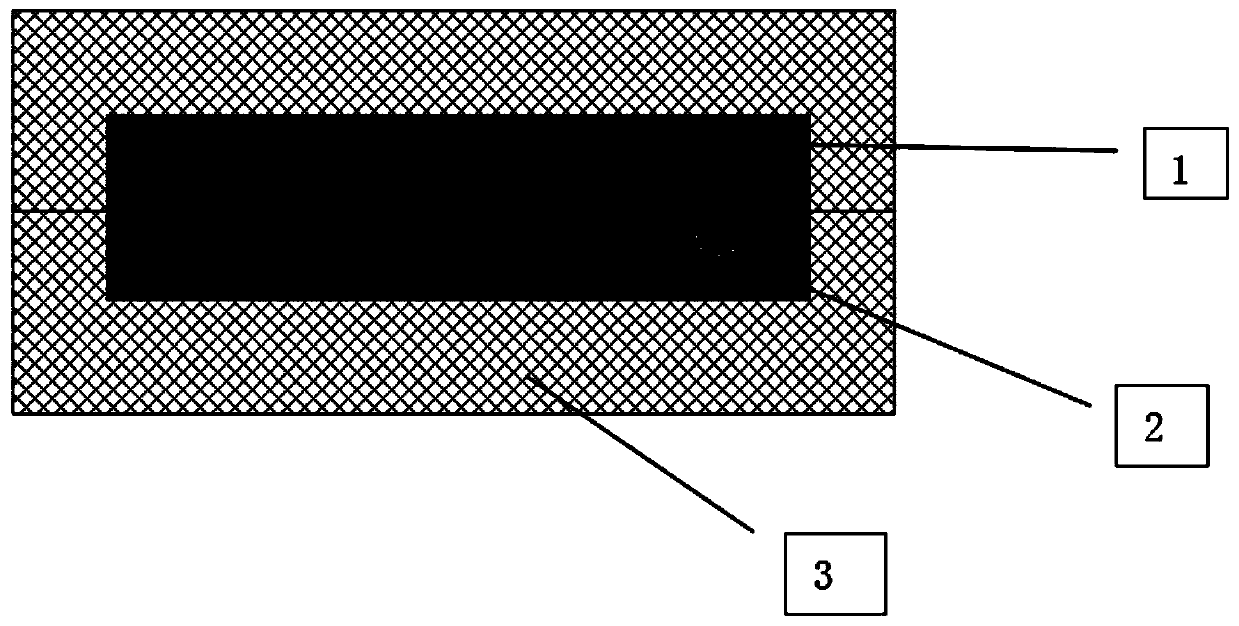

[0047] Example 1: Preparation of foam with thermal self-expansion function

[0048] Cutting: Cut the rigid foam according to the size of the product;

[0049] Spraying: Spray a layer of thermal self-expanding resin on the outer layer of the rigid foam. The coating thickness is 0.1mm by cross-spraying.

[0050] The prepared foam with thermal self-expansion function:

[0051] Initial tackiness to the finger touch, when the finger is pressed against the surface of the thermally self-expanding resin layer for 15 seconds, the resin layer sticks to the hand, but does not transfer to the finger;

[0052] The prepared foam was placed in an oven at 150°C and heated for 30 minutes, and the expansion ratio (volume ratio before and after heating) was 1:1.18.

[0053] The prepared foam is put into a closed mold of equal volume and heated at 150° C. The resulting expansion pressure is 0.11Mpa.

Embodiment 2

[0054] Example 2: Preparation of foam with thermal self-expansion function

[0055] Cutting: Cut the rigid foam according to the size of the product;

[0056] Spraying: Spray a layer of thermal self-expanding resin on the outer layer of the rigid foam. It adopts three-pass spraying method with a coating thickness of 0.3mm.

[0057] The prepared foam with thermal self-expansion function:

[0058] The initial tackiness of the finger touch, the finger presses the surface of the thermally self-expanding resin layer for 5 seconds, the resin layer sticks to the hand, but does not transfer to the finger;

[0059] The prepared foam was placed in an oven at 150°C and heated for 30 minutes, and the foaming ratio (volume ratio before and after heating) was 1:1.46.

[0060] The prepared foam is put into a closed mold of equal volume and heated at 150°C, and the resulting expansion pressure is 0.58Mpa.

Embodiment 3

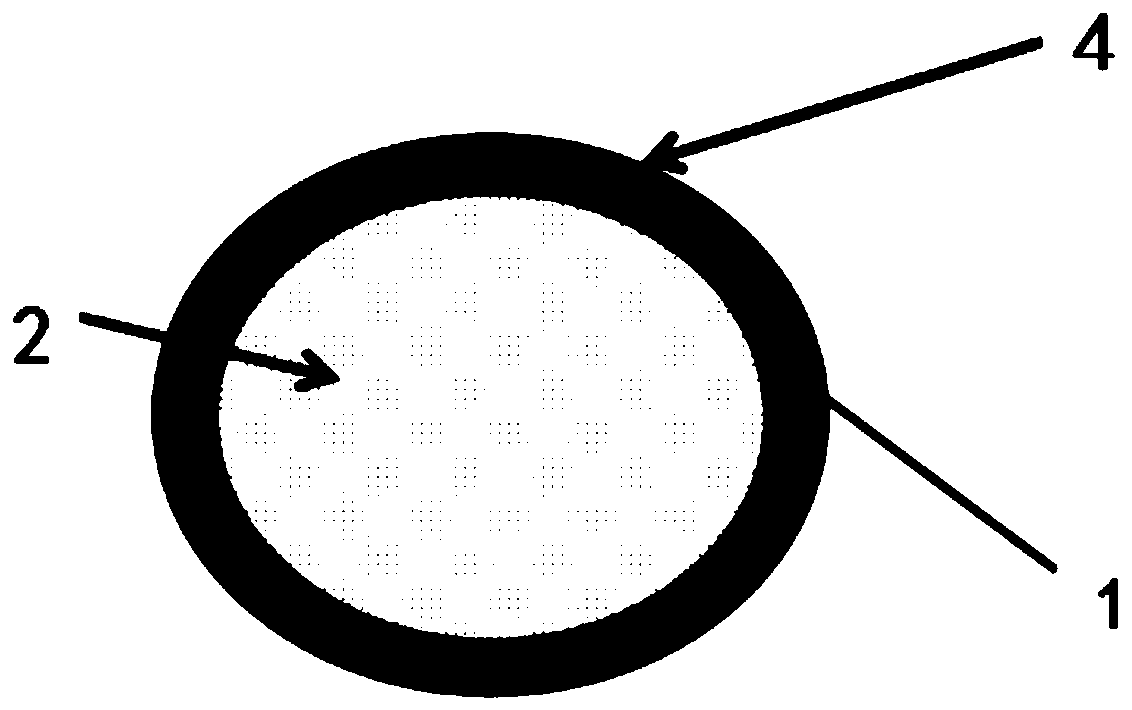

[0061] Example 3: Preparation of foam with thermal self-expansion function

[0062] Cutting: Cut the rigid foam according to the size of the product;

[0063] Pouring: Put the cut rigid foam into the mold, and then pour the hot self-expanding resin into the mold; just open the mold and take it out.

[0064] Calculate the amount of thermally self-expandable resin required according to 1.1 times the volume of the cavity between the rigid foam and the mold (refers to the amount of thermally self-expandable resin that is 1.1 times the volume of the void between the rigid foam and the mold) .

[0065] The perfusion rate is controlled at 1.5kg / min.

[0066] The prepared foam with thermal self-expansion function:

[0067] Initial tackiness to the finger touch, pressing the surface of the thermally self-expanding resin layer with the finger for 8 seconds, the resin layer sticks to the hand, but does not transfer to the finger;

[0068] The prepared foam was placed in an oven at 150° C. and heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com