Automatic production apparatus for grinding powder paint

A powder coating, automatic production technology, applied in the direction of sounding equipment, solid separation, sieve, etc., can solve the problems of unstable manual weighing error, dust leakage, and high quality of operators, to reduce the amount of dust leakage, stabilize The effect of continuous production and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

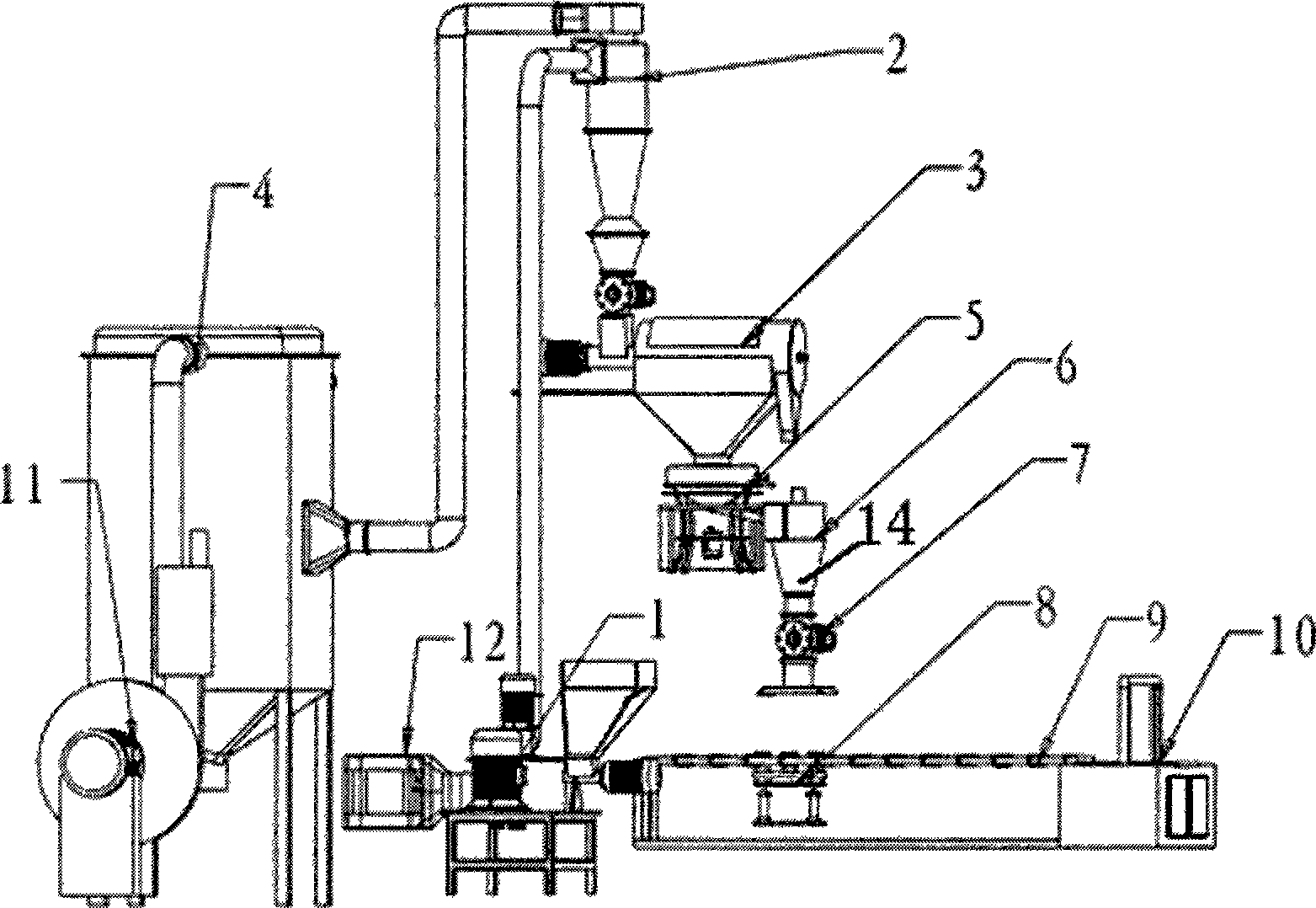

[0028] The powder coating grinding automatic production equipment reference of this embodiment Figure 1-10 , the powder coating semi-finished product from the extrusion process is crushed through the grinding head 1, and then graded into the cyclone separator 2. Through the action of centrifugal force, the superfine powder with particle size is taken out by the wind and enters the dust collector 4, where there are Bag filter, and finally settled in the dust collector. The powder coating with coarser particle size settles at the bottom of the cyclone separator, and is sent to the rotary screen 3 by the discharger, the powder coating with a qualified particle size is screened out and enters the vibrating screen 5, and the powder coating with a coarser particle size is spun out of the rotary screen outlet. out, recycle.

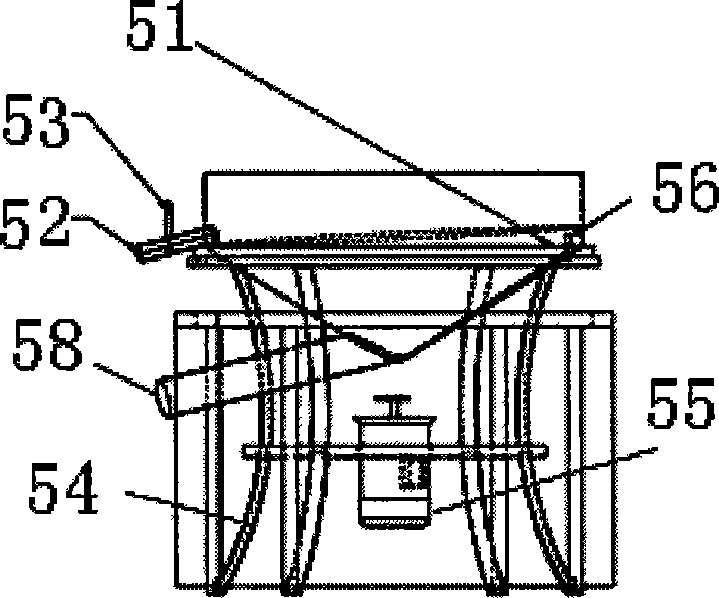

[0029] The powder entering the vibrating sieve 5 is sieved by the vibrating sieve, and the sieve residue brought out due to the crushing of the rotating sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com