Forming method of hard alloy bar with spiral hole

A technology of cemented carbide rods and forming methods, applied in the field of cemented carbide, which can solve the problems of complex structure and inability to produce porous cemented carbide rods, and achieve the effect of stable helix angle and stable diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

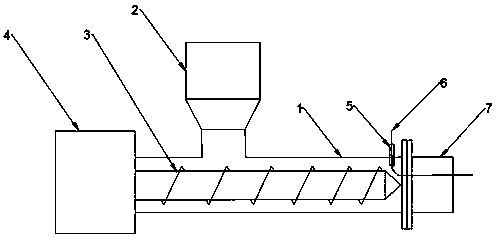

[0029] like figure 1 As shown, this embodiment provides a screw extrusion molding device for cemented carbide rods with spiral holes, including a screw extruder and a die head 7, and the die head used in this embodiment is a rotary die head. The screw extruder includes a driving motor 4 and a barrel 1. The driving motor 4 is located at one end of the barrel 1. The barrel 1 is provided with a feeding hopper 2 used as a feeding port, and a rotary die 7 is installed on the discharging port. The barrel 1 is provided with a screw 3 , the screw 3 is in clearance fit with the barrel 1 , and the screw 3 is connected with the drive motor 4 .

[0030] In this embodiment, the end of the extruder is provided with a rotary die 7 having the same shape as the cemented carbide rod, a through hole 5 is provided on the barrel 1 of the extruder, and a polymer wire 6 is introduced into the through hole ; Die head 7 is connected with the extruder with a guide hole; the polymer wire 6 passes throu...

Embodiment 2

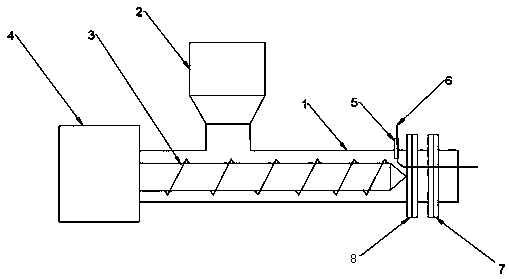

[0032] like figure 2 As shown, this embodiment refers to Embodiment 1, and provides a screw extrusion molding device for cemented carbide rods with spiral holes. In this embodiment, a shaping die is also provided between the rotary die 7 and the extruder. The head 8, the sizing die 8 is provided with a positioning hole, and the position of the positioning hole on the sizing die 8 corresponds to the position of the guide hole of the rotating die 7. The sizing die 8 is fixedly connected to the extruder, and the rotating die 7 is connected to the sizing die 8 .

[0033] In this embodiment, a through hole 5 is provided on the barrel 1, a positioning hole is provided on the sizing die 8, and a guide hole is provided on the rotating die 7. The positioning holes correspond to the positions of the guide holes, and the polymer wires 6 are arranged in sequence. Pass through the through hole 5, the positioning hole and the guide hole. The number of through holes 5, positioning holes a...

Embodiment 3

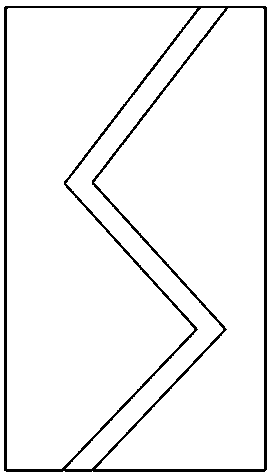

[0036] This embodiment provides a process for forming a cemented carbide bar with a spiral hole, the number of spiral holes is one, and the following steps are included:

[0037] Carbide rods were prepared on the extruder provided in Example 1. The end of the extruder was provided with a rotating die, the rod was extruded into the die, and a polymer was introduced from the through hole of the extruder. Rotating the die head, the polymer wire passes through the through hole on the barrel and the guide hole on the rotary die head in turn, and is fixed at the corresponding position of the cemented carbide section; when the die head is rotated, the polymer wire is driven by the die head at the same speed. Rotate to obtain a polymer wire with a helix angle in the cemented carbide; heat the cemented carbide rod to above 1000 ° C, the polymer wire is decomposed, and a cemented carbide rod with a helical hole is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com