Porous water-containing gel molded article, method for producing same, and use of same

一种制造方法、成型物的技术,应用在化学仪器和方法、可持续生物处理、生物水/污水处理等方向,能够解决不具有孔、不理想等问题,达到抑制负担、降低污浊物质及水量、栖息性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Water was added to PVA (manufactured by Kuraray Co., Ltd., average polymerization degree 1700, saponification degree 99.8 mol%) to a PVA concentration of 6.0 g / L, and the PVA was dissolved in hot water for 60 minutes. Sodium alginate was added to this PVA aqueous solution to make it 1 g / L, and it stirred and dissolved for 30 minutes. Furthermore, 50% glutaraldehyde aqueous solution was added to this aqueous solution so that the mole number with respect to the total monomer unit in PVA might become 3.7 mol%, Then, it mixed well and prepared the mixed aqueous solution. 100 g of this mixed aqueous solution was delivered at a rate of 5 mL / min by using a roller pump equipped with a silicone tube with an inner diameter of 3.2 mm and a nozzle with an inner diameter of 2 mm at the tip, and added dropwise to 1 L with stirring. In the primary coagulation liquid composed of a calcium chloride aqueous solution with a concentration of 0.1 mol / L that was stirred by a device. The add...

Embodiment 2

[0119] In Example 1, the sulfuric acid concentration of the secondary coagulation liquid (B) was 30 g / L, and the sodium sulfate concentration was 150 g / L, except that, by the same method as in Example 1, a gel molded product was produced ( C). As a result, a flexible spherical gel-shaped product (C) having a diameter of about 5.3 mm was obtained. Various measurements were performed in the same manner as in Example 1 for the obtained gel-formed product (C). The results are shown in Table 1.

Embodiment 3

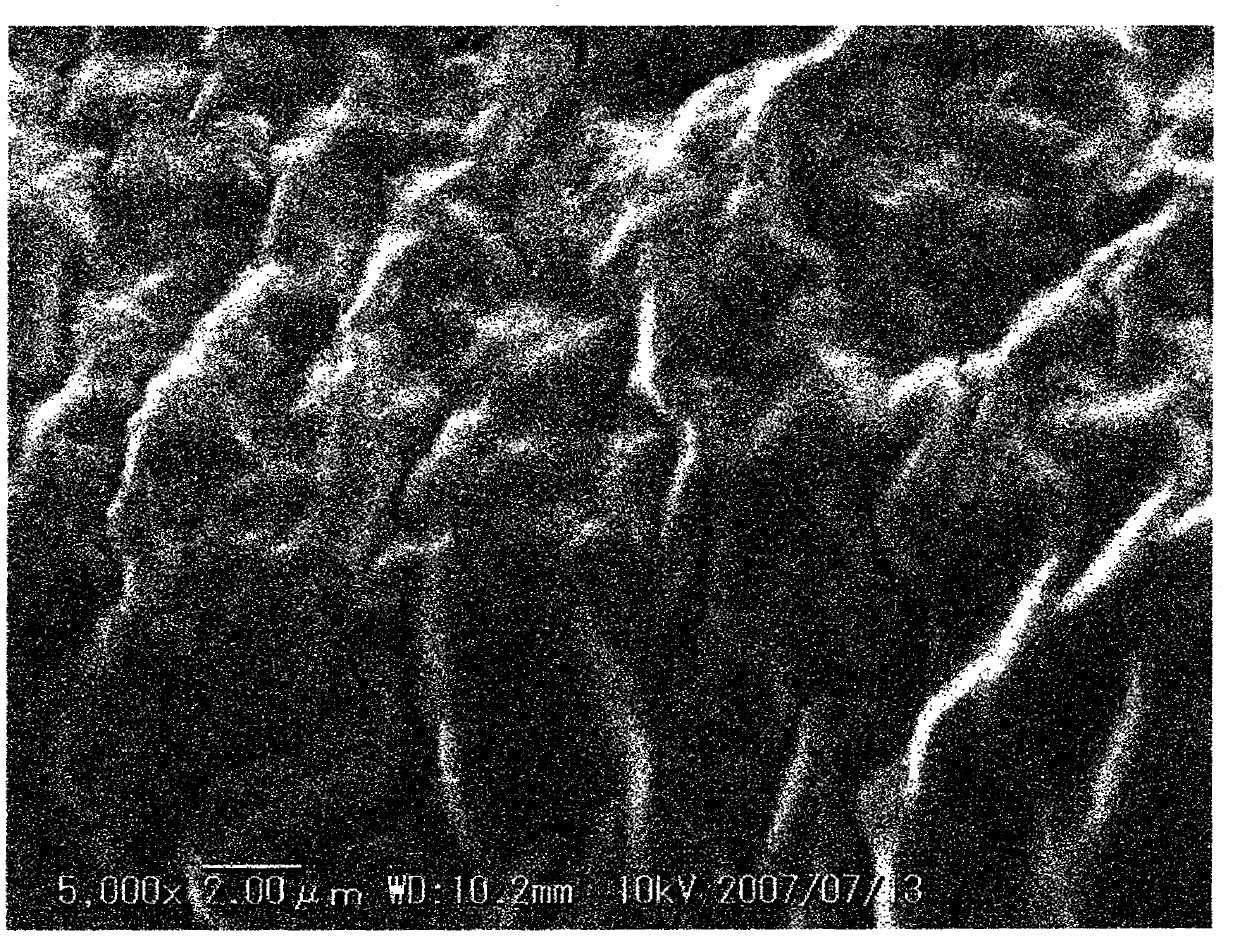

[0121] In Example 1, modified starch was added to the mixed aqueous solution to make it 0.3g / L, and the concentration of sulfuric acid in the secondary coagulation liquid (B) was 30g / L, and the concentration of sodium sulfate was 150g / L. , By the same method as in Example 1, a gel molded product (C) was produced. As a result, a flexible spherical gel-shaped product (C) having a diameter of about 5.3 mm was obtained. The SEM photograph of the surface of the gel molding (C) of Example 3 is shown in Figure 8 . From the obtained SEM photograph, it can be seen that a large number of pores of about 2 to 20 μm exist on the surface of the gel-formed product (C) of Example 3. Various measurements were performed in the same manner as in Example 1 for the obtained gel-formed product (C). The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| degree of acetalization | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com