Ultrathin lithium-rich alloy with embedded three-dimensional skeleton structure as well as preparation method and application of ultrathin lithium-rich alloy

A three-dimensional skeleton, lithium alloy technology, applied in structural parts, lithium batteries, electrical components, etc., can solve the problems of unsuitable alloy layers, limited applications, and difficulty in large-scale preparation of lithium alloy thin film layers, achieving a wide range of applications and high efficiency. The effect of continuous production and wide practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

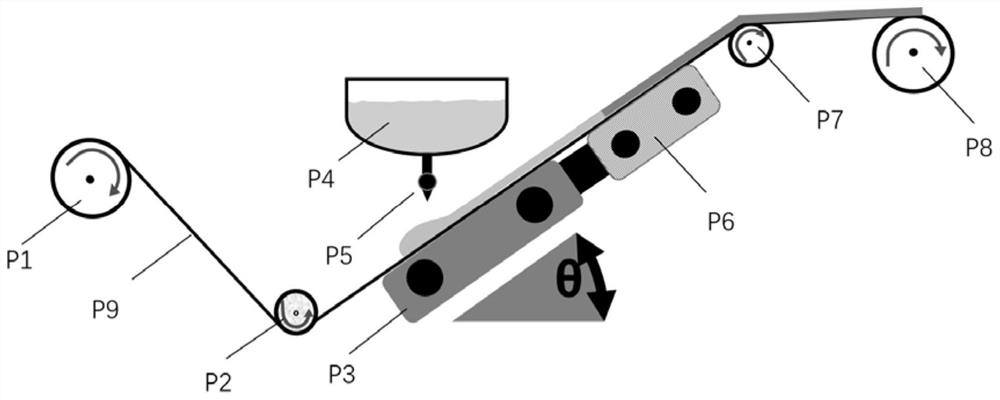

[0038] This example provides a production system for an ultra-thin lithium-rich alloy with an embedded three-dimensional skeleton structure, such as figure 1As shown, it includes substrate roll device P1 connected in sequence (casting substrate P9 required for production is on the roll), lower tension roll device P2, upper tension roll device P7 and finished product collection roll device P8, lower tension roll A heating and heat preservation platform P3 and a cooling platform P6 are sequentially arranged between the device P2 and the upper tension roller device P7, a heating device P4 is arranged above the heating and heat preservation platform P3, and a discharge port P5 is arranged below the heating device P4.

[0039] In the present invention, the substrate roller device P1, the lower tension roller device P2, the upper tension roller device P7 and the finished product collection roller device P8 cooperate with each other to realize the transmission of the casting substrate...

Embodiment 2

[0042] A preferred embodiment of the present invention provides a method for preparing an ultra-thin lithium-rich alloy, the specific steps are as follows:

[0043] In this example, the ultra-thin metal lithium foil production system of Example 1 is adopted, and the metal lithium is placed in the heating device P4, and the temperature is raised to 200° C. to obtain molten lithium liquid, and the metal indium with a mass ratio of 5% is added, and stirred After uniformity, the discharge port P5 transfers the molten lithium-rich alloy liquid to the polyimide film substrate P9 placed at an angle, the inclination angle θ is adjusted to 60°, the temperature of the heating and heat preservation platform 3 is maintained at 200 °C, and the cooling platform 6 The temperature was maintained at 25°C. The liquid molten lithium alloy on the surface of the inclined substrate has a tendency to flow downward. At the same time, the transmission equipment P1, P2, P7, and P8 drive the substrate t...

Embodiment 3

[0045] A preferred embodiment of the present invention provides a method for preparing an ultra-thin lithium alloy, the specific steps are as follows:

[0046] In this example, the ultra-thin metal lithium foil production system of Example 1 is adopted, the metal lithium is placed in the heating device P4, and the temperature is raised to 260°C to obtain molten lithium liquid, then 8% by mass of magnesium metal is added, and stirred After uniformity, the discharge port P5 transfers the molten lithium-rich alloy liquid to the copper foil substrate P9 placed at an angle, the inclination angle θ is adjusted to 85°, the temperature of the heating and heat preservation platform 3 is kept at 250°C, and the temperature of the cooling platform 6 is kept at 15°C. The liquid molten lithium alloy on the surface of the inclined substrate has a tendency to flow downward. At the same time, the transmission equipment P1, P2, P7, and P8 drive the substrate to move upward at a constant speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com