Compressor and pressure control method thereof

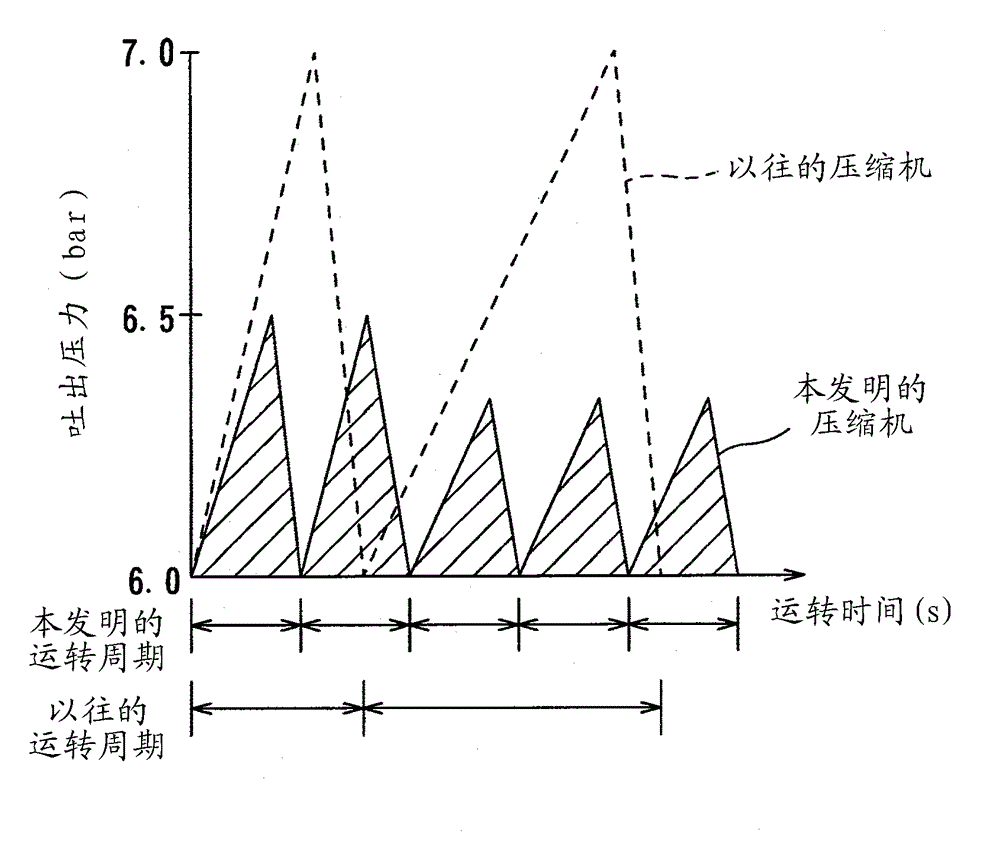

A pressure control, compressor technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as loss, and achieve the effect of boosting energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

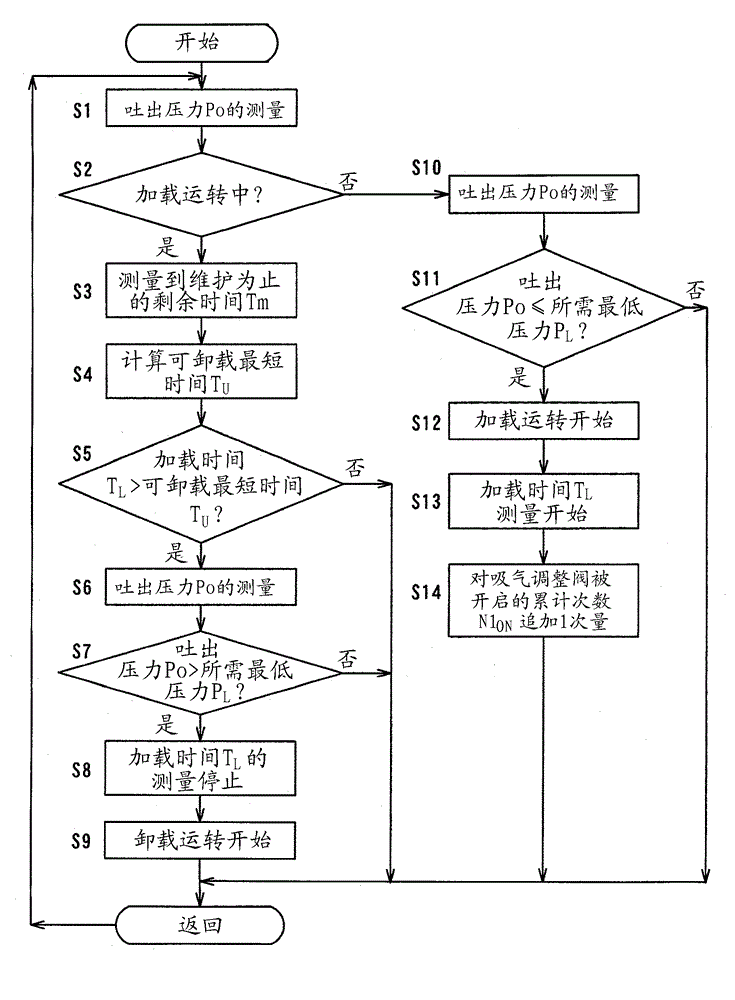

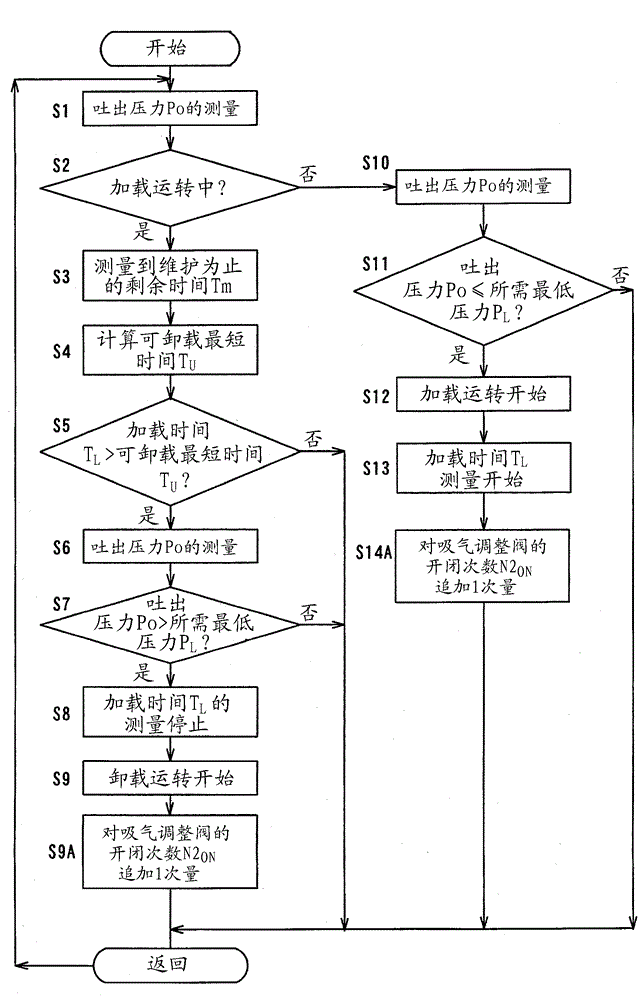

[0045]Embodiments of the present invention will be described below with reference to the drawings.

[0046] figure 1 An example of a compressor according to an embodiment of the present invention is shown. The compressor 10 is, for example, a screw compressor, and includes a compressor main body 1 having a suction port 10 a for sucking gas in and a discharge port 10 b for discharging the gas sucked in from the suction port 10 a and compressed. The compressor body 1 is connected to a suction flow path 2 that sucks gas from the outside and guides it to the suction port 10a, and a discharge flow path 5 that supplies the gas compressed by the compressor body 1 to the discharge side through the discharge port 10b. . The suction flow path 2 is provided with a suction filter 3 for removing foreign matter from the sucked gas, and an intake control valve 4 for opening and closing the suction flow path 2 .

[0047] When the suction regulating valve 4 is opened, the suction flow path...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com