Solar silicon wafer two-in-one automatic loading and unloading equipment

A technology of automatic loading and unloading and solar silicon wafers, which is applied in the direction of conveyor objects, photovoltaic power generation, electrical components, etc., can solve the problems of large space occupation, affecting production efficiency, and long cycle time, so as to improve work efficiency and save equipment space , The effect of shortening the feeding and discharging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

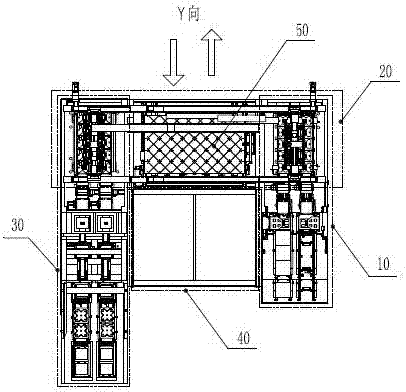

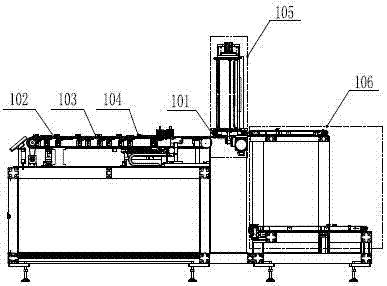

[0056] refer to figure 1 , the two-in-one automatic loading and unloading equipment for solar silicon wafers provided by the present invention is installed on the feeding and discharging end of the main equipment for loading and unloading of the main equipment, and it includes: a loading module 10, a transfer module 20, a lower The material module 30 and the lifting platform 40; the loading module 10 and the unloading module 30 are respectively located on both sides of the lifting platform 40, and the upper part of the material outlet of the loading module 10 and the upper part of the material inlet of the unloading module 30 are respectively provided with transfer The module 20 and the lifting platform 40 are connected to the feed and discharge ends of the main equipment alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com