Motor driven resistance spot welding gun

A technology of motor drive and welding torch, which is applied in the direction of resistance welding equipment, resistance electrode base, electromechanical device, etc. It can solve the problems of damage, etc., and achieve the effect of simple structure, equipment reduction and equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Best Mode for Carrying Out the Invention

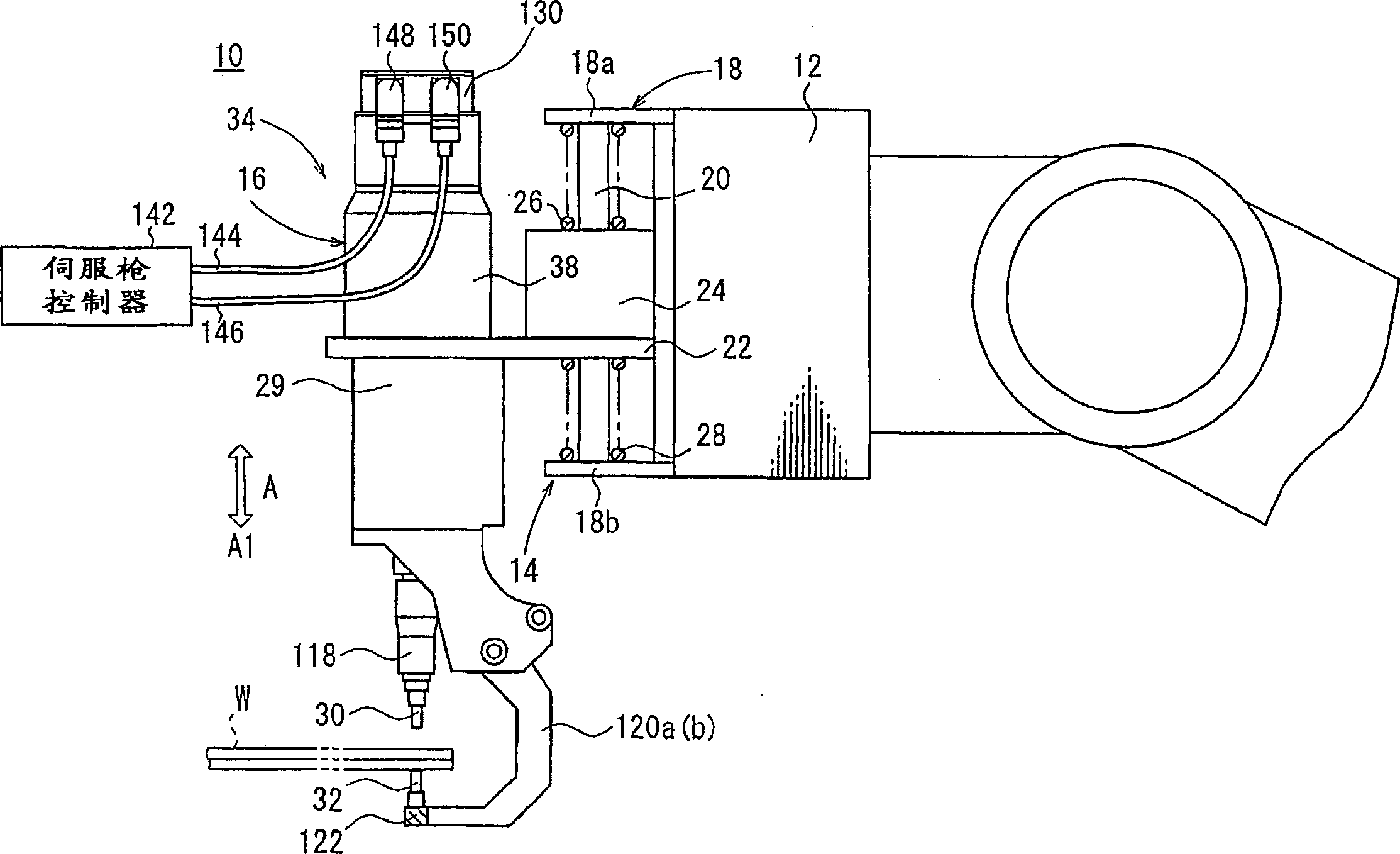

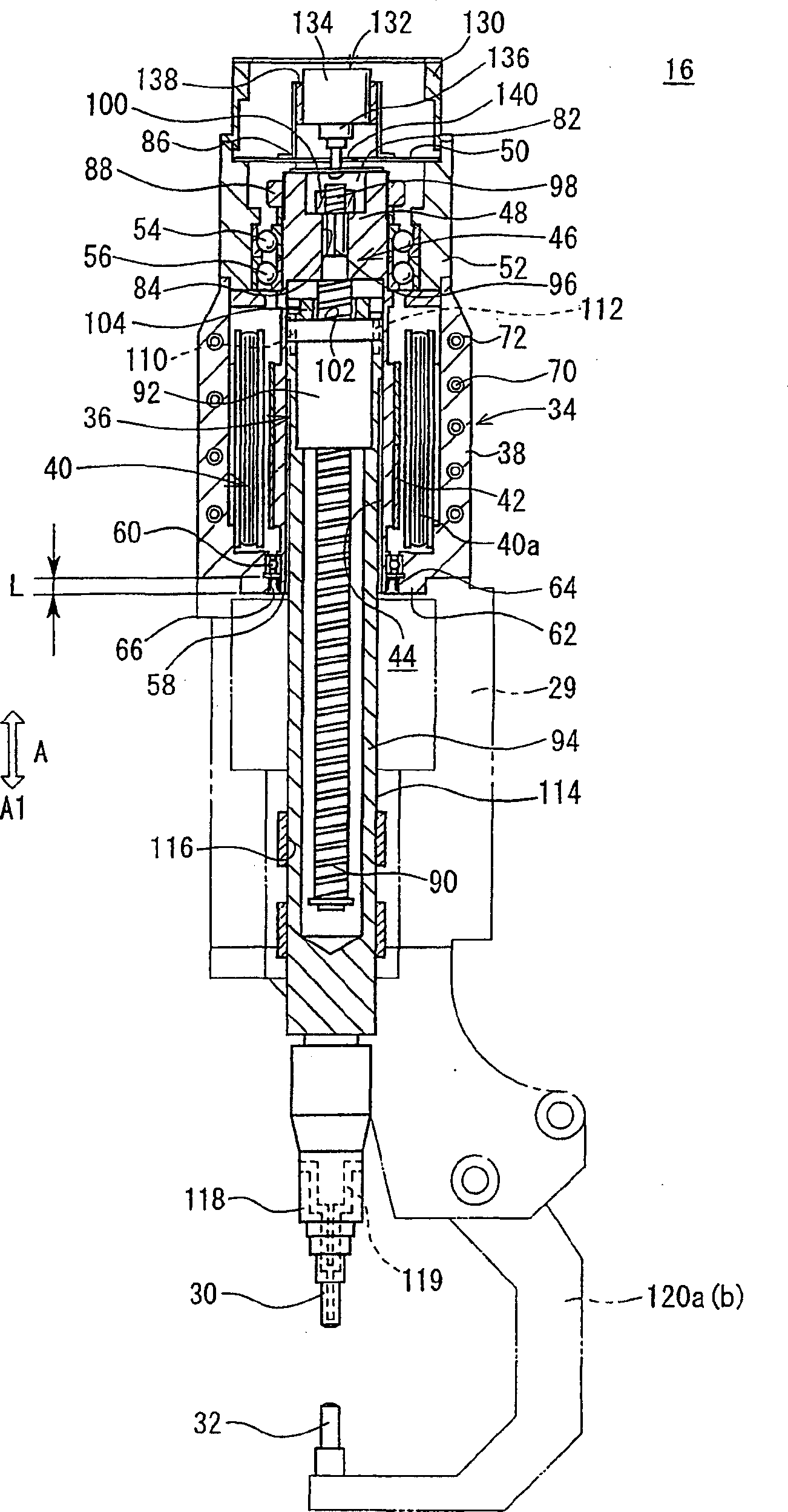

[0045] figure 1 Shown is a side view, partly omitted from illustration, of a motor-driven welding gun fastening device according to a first embodiment of the invention, the welding gun being mounted at the distal end of the robot arm 12 . The motor-driven welding torch 10 is configured as a C-shaped welding torch having a movable electrode tip 30 that can move linearly toward or away from a fixed electrode tip 32 . However, the motor-driven welding torch 10 is not limited to such a C-shaped welding torch, but may be provided as an X-shaped welding torch having a movable electrode tip that can swing relative to a fixed electrode tip.

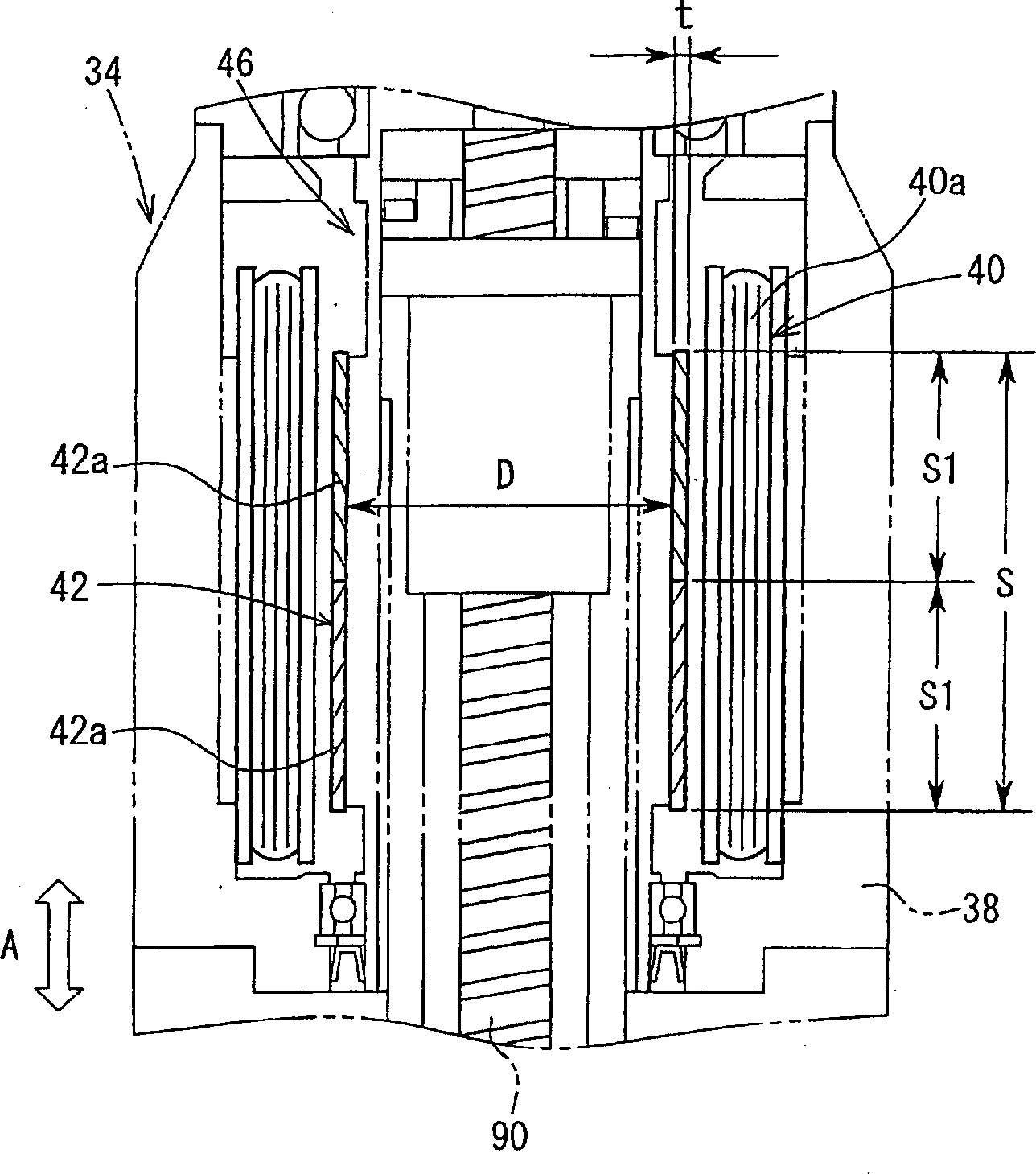

[0046] The motor driven welding gun 10 includes a welding gun bracket 14 and a welding gun assembly 16 . A welding torch bracket 14 is mounted on the distal end of the robot arm 12 and supports a welding torch assembly 16 . The torch holder 14 has a torch holder frame 18 with an upper panel 18a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com