Cradle for pouring bridge cantilever and construction method of cradle

A construction method and cantilever technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of steel lashing occupying the cantilever pouring process time and other problems, and achieve the effect of being beneficial to linear control, shortening the occupation time, and shortening the cycle period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

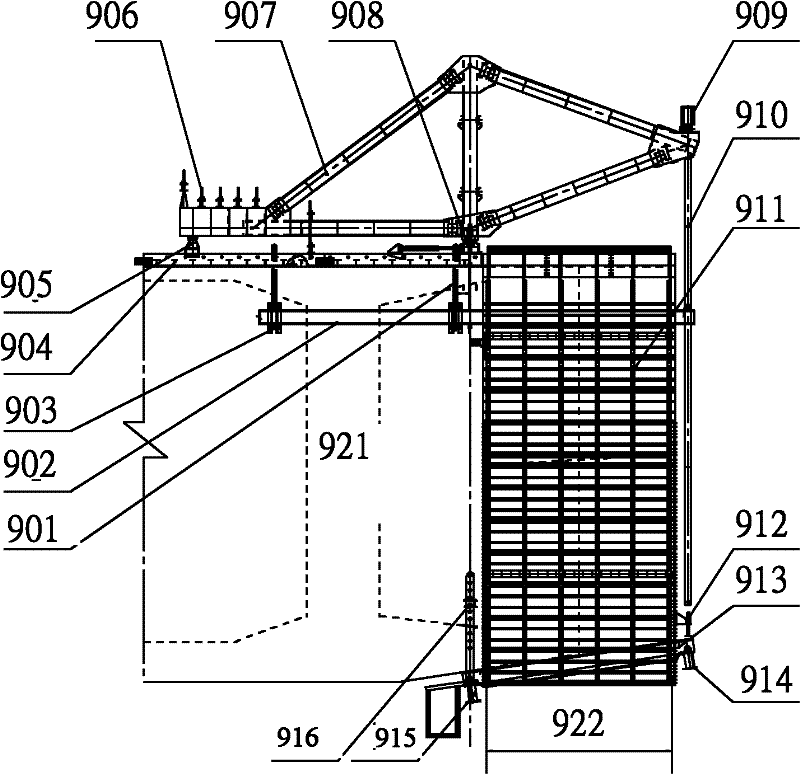

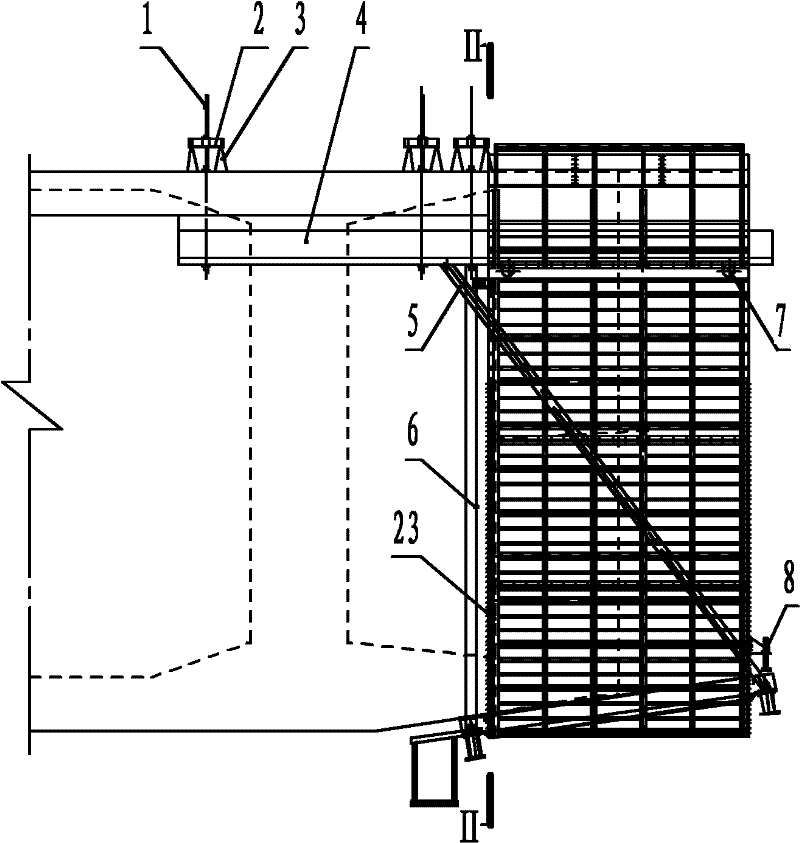

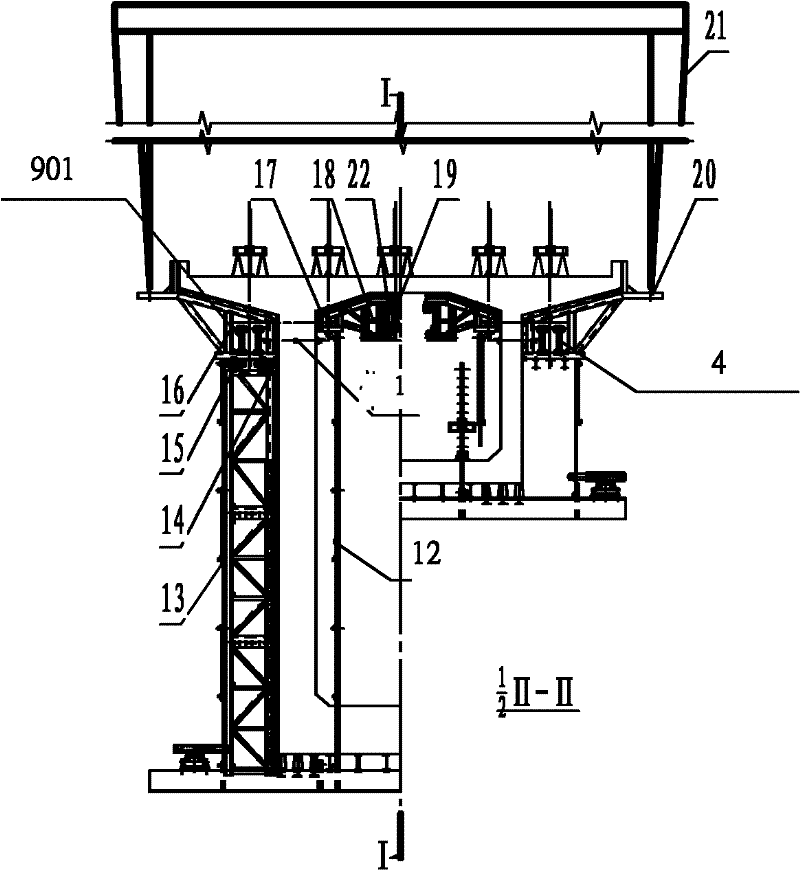

[0020] In order to overcome the problem that steel bar binding occupies the cantilever pouring process time when the traditional hanging basket is used, the present invention proposes an open hanging basket without bridge deck support and a construction method for bridge cantilever pouring construction. The hanging basket includes a bottom formwork system, a side Formwork system, internal formwork system, anchoring system, running system and hoisting system, the running system is used to realize the running and moving of the hanging basket, and the bottom formwork system, side formwork system and internal formwork system are anchored on the completed beam section through the anchorage system , to form an open hanging basket structure without bridge deck support, and the hoisting system is used to hoist the pre-bound steel skeleton. Correspondingly, the construction method includes the following steps: S1, pouring concrete, curing, demoulding, and tensioning the prestressed stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com