Method for sludge reduction using ultrasonic treatment

An ultrasonic and sludge technology, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of high operating costs, large investment, immature technology, etc., and achieve stable output, high economic benefits, The effect of saving construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

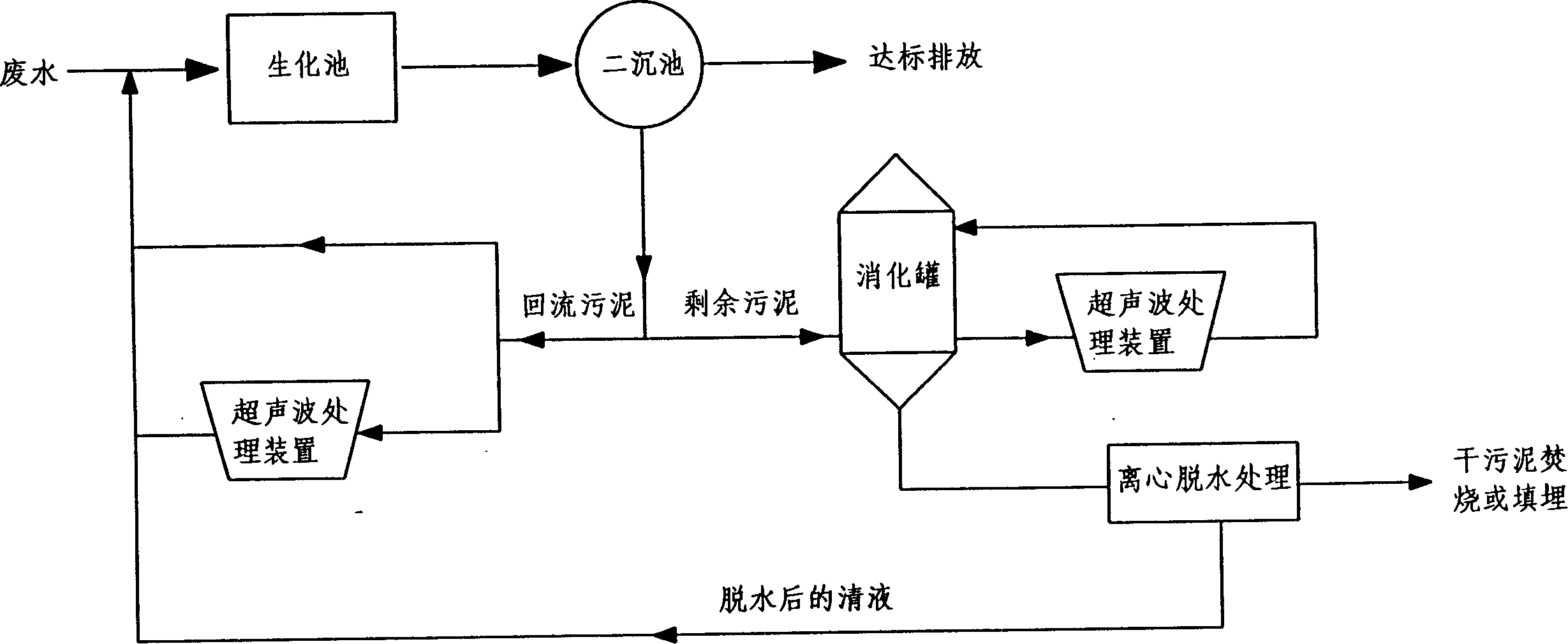

[0027] see figure 1 According to the present invention, the method for treating sludge with ultrasonic wave to reduce sludge volume includes biochemical unit, sedimentation unit, sludge anaerobic digestion unit, ultrasonic treatment unit and sludge dehydration unit.

[0028] The biochemical unit concentrates the sludge in the biochemical pool, effectively removes organic pollutants through microorganisms, and transforms organic compounds into inorganic small molecular substances. Since urban sewage itself contains a large number of microorganisms, including anaerobic bacteria and aerobic bacteria, according to the characteristics of each urban sewage, when choosing anaerobic treatment, a closed biochemical pool is used to make the anaerobic bacteria multiply; During oxygen treatment, the sewage is filled with air through the aerator to increase the oxygen content in the sewage and make the aerobic bacteria multiply. Generally speaking, the hydraulic retention time of aerobic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com