System for warming methane tank by ground source/air source heat pump and control method

An air source heat pump and ground source heat pump technology, applied in the field of energy saving, can solve the problem of no relatively economical, reasonable, energy-saving and environmentally friendly heating method, and achieve the effects of simple structure, low energy consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

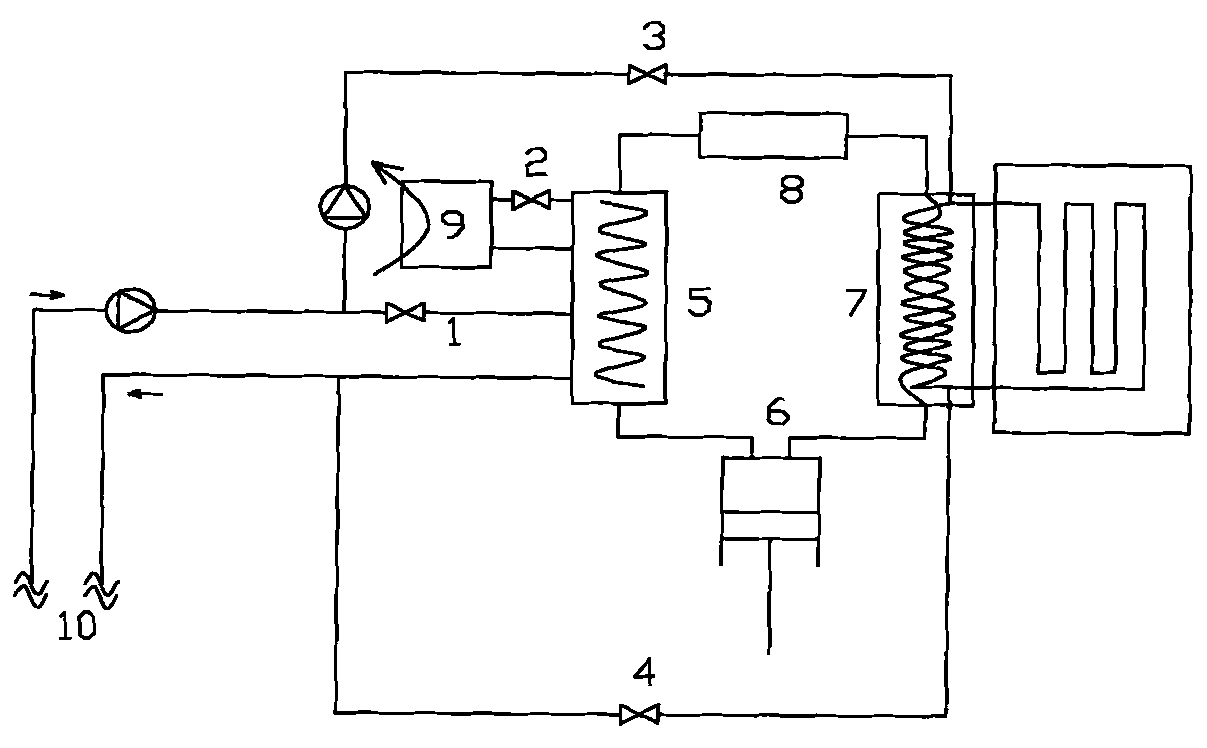

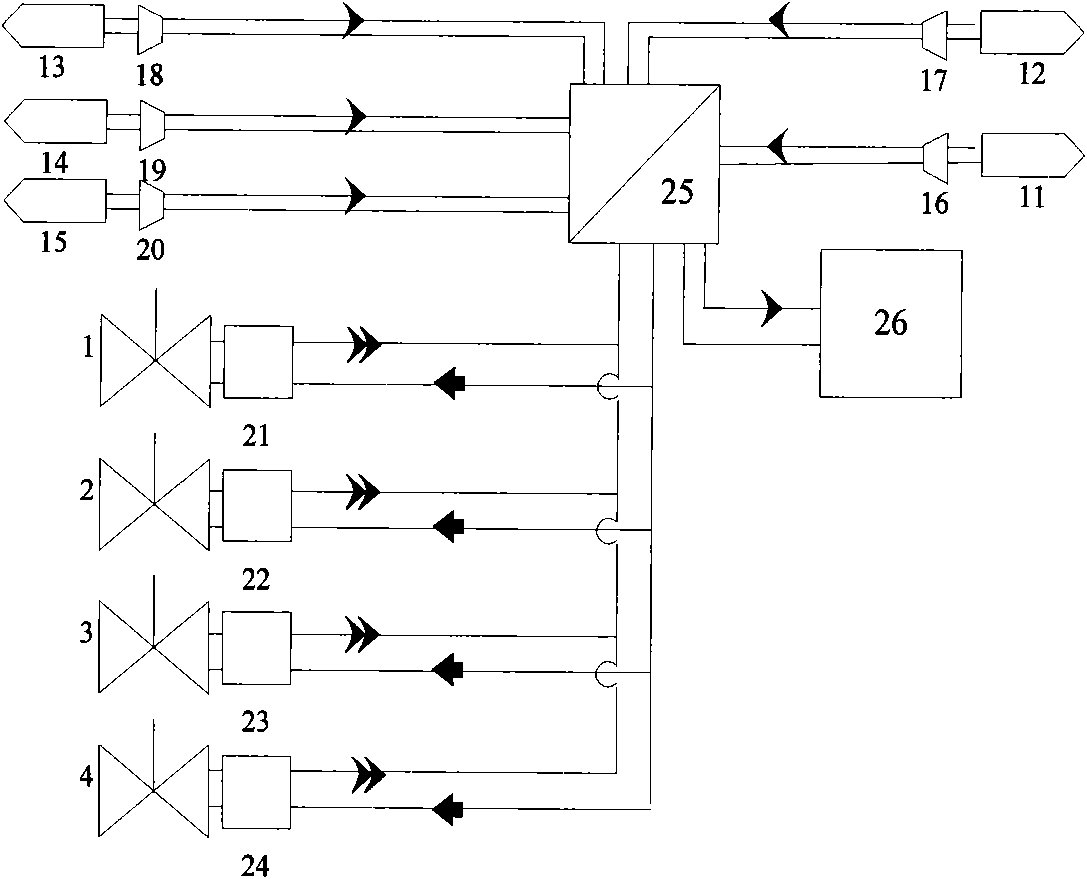

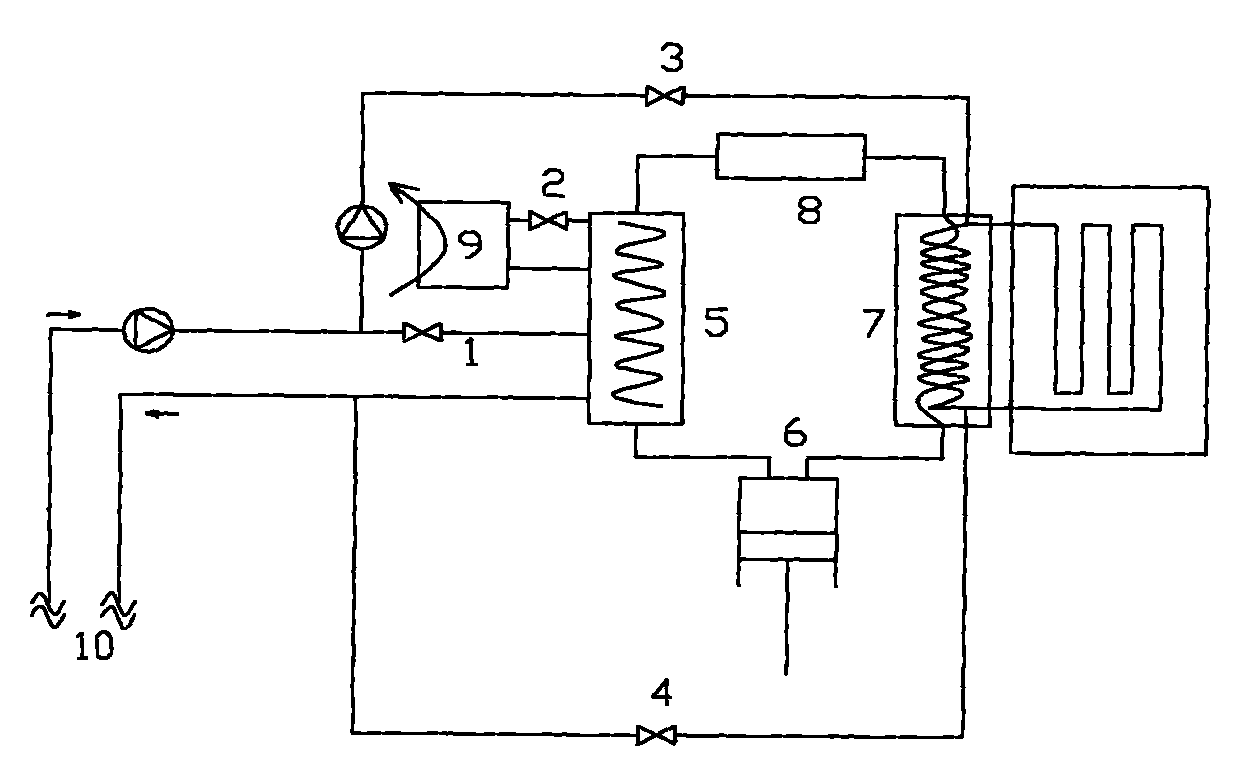

[0022] Embodiment 1: as Figure 1-Figure 2 As shown, the system is composed of an underground loop 10, air cooling equipment 9, ground source / air source heat pump common units and a control system. The control parameter collection part in the control system includes an ambient temperature sensor 11, an average soil temperature sensor The outlet water temperature sensor 13 of the source heat pump unit, the inlet water temperature sensor 14 of the ground source heat pump unit and the biogas tank temperature sensor 15 are all DS18B20 temperature sensors to collect temperature signals. The temperature control part of the biogas tank in the control system is composed of a signal generator, an actuator, a single-chip microcomputer 25 and a computer 26. The single-chip microcomputer 25 and the computer 26 are connected by an R232 interface signal line, and the rest are directly connected by signal lines to realize automatic control. The underground loop 10 is a buried pipe and some v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com