Fluidized bed reaction device and reaction method for coal catalytic gasification for producing methane-rich synthetic gas

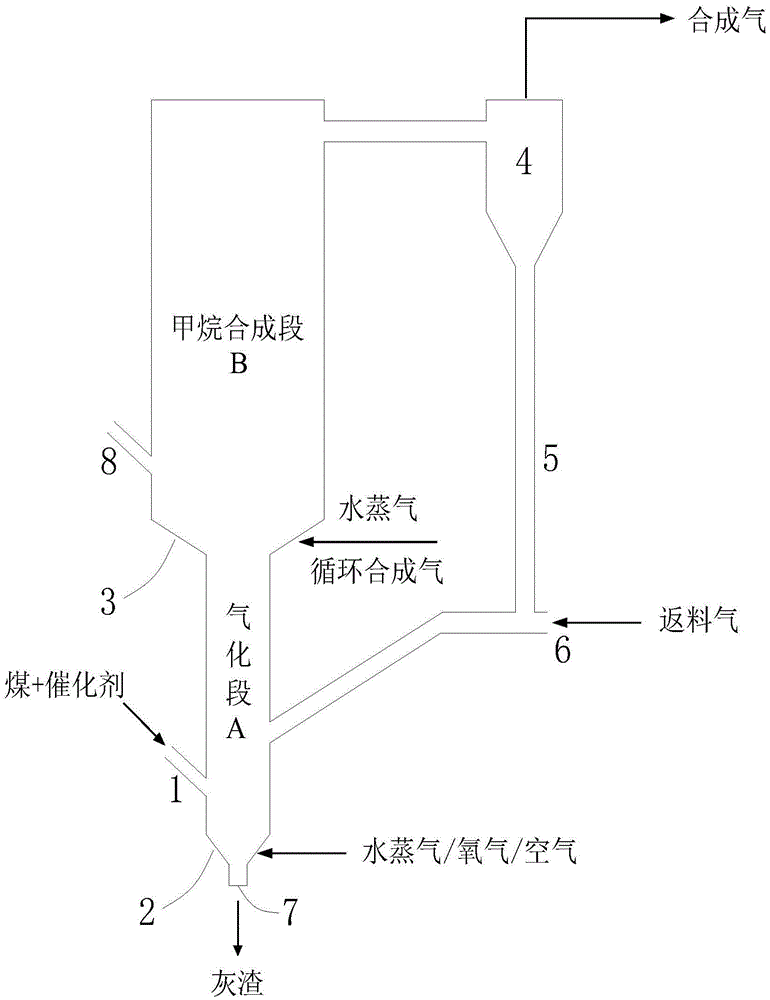

A technology for methane synthesis gas and coal catalytic gasification, which is used in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the production of bulk chemicals, which can solve the problems of low carbon conversion rate, low methane yield, and complex structure. , to achieve the effect of improving carbon conversion rate, simple and compact structure, and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

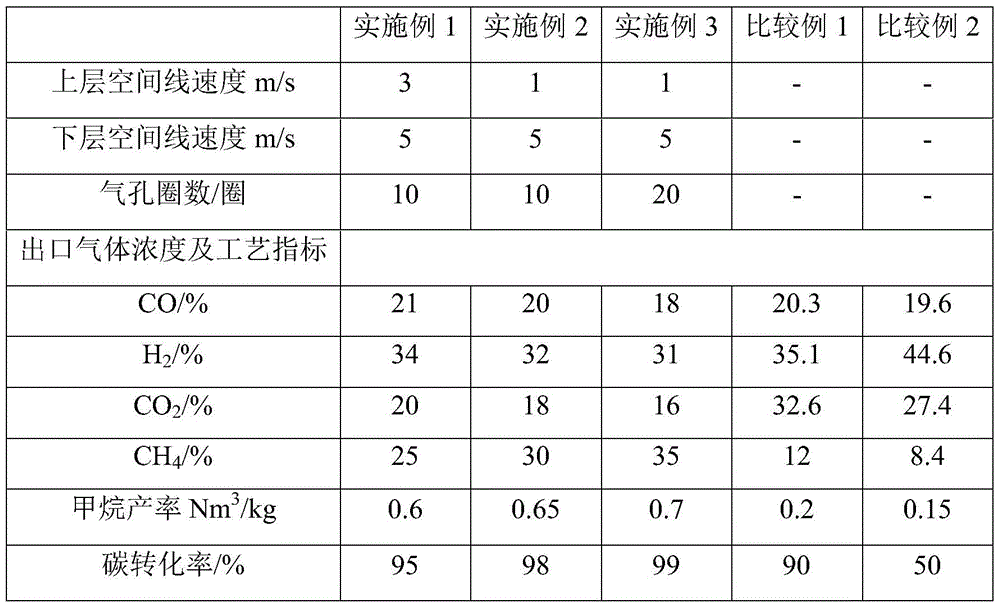

Embodiment 1

[0036] In this embodiment, the inner diameter of the lower space of the gasification device is 0.1m, and the height is 5m. The inner diameter of the upper space is 0.2m, and the height is 6m. The two-layer gas distributor is set, and the air holes are evenly arranged along the circumference. There are 10 circles of air holes. The ratio is 2%, the angle between the inclined surface of the gas distributor and the horizontal axis is 30°, and an auxiliary feed port is set to supplement the catalyst. In the experiment, Inner Mongolia lignite was selected, and it was crushed to make pulverized coal below 1mm. Potassium carbonate was used as the catalyst, and 10% potassium carbonate catalyst was mixed with pulverized coal evenly. After drying for 24 hours, a mixture with a water content of less than 5% was obtained. Supplementary Potassium carbonate catalyst was 10% of the downspace catalyst. The mixture of pulverized coal and catalyst is added to the gasifier, high-temperature water...

Embodiment 2

[0038] In this embodiment, the inner diameter of the lower space of the gasification device is 0.1m, and the height is 5m. The inner diameter of the upper space is 0.3m, and the height is 6m. The two-layer gas distributor is set, and the air holes are evenly arranged along the circumference. There are 10 circles of air holes. The ratio is 2%, the angle between the inclined surface of the gas distributor and the horizontal axis is 30°, and an auxiliary feed port is set to supplement the catalyst. In the experiment, Inner Mongolia lignite was selected, and it was crushed to make pulverized coal below 1mm. Potassium carbonate was used as the catalyst, and 10% potassium carbonate catalyst was mixed with pulverized coal evenly. After drying for 24 hours, a mixture with a water content of less than 5% was obtained. Supplementary Potassium carbonate catalyst was 10% of the downspace catalyst. The mixture of pulverized coal and catalyst is added to the gasifier, high-temperature water...

Embodiment 3

[0040] In this embodiment, the inner diameter of the lower space of the gasification device is 0.1m, and the height is 5m. The inner diameter of the upper space is 0.3m, and the height is 6m. The two-layer gas distributor is set, and the air holes are evenly arranged along the circumference. There are 20 circles of air holes. The ratio is 2%, the angle between the inclined surface of the gas distributor and the horizontal axis is 30°, and an auxiliary feed port is set to supplement the catalyst. In the experiment, Inner Mongolia lignite was selected, and it was crushed to make pulverized coal below 1mm. Potassium carbonate was used as the catalyst, and 10% potassium carbonate catalyst was mixed with pulverized coal evenly. After drying for 24 hours, a mixture with a water content of less than 5% was obtained. Supplementary Potassium carbonate catalyst was 10% of the downspace catalyst. The mixture of pulverized coal and catalyst is added to the gasifier, high-temperature water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com