Method for producing methane by enhancing anaerobic digestion of municipal sludge based on electron transfer

An anaerobic digestion and municipal sludge technology, applied in biological sludge treatment, waste fuel, etc., can solve the problems of low methane production efficiency, slow hydrolysis acidification rate, etc., to improve methane production, accelerate hydrolysis acidification and methane generation, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

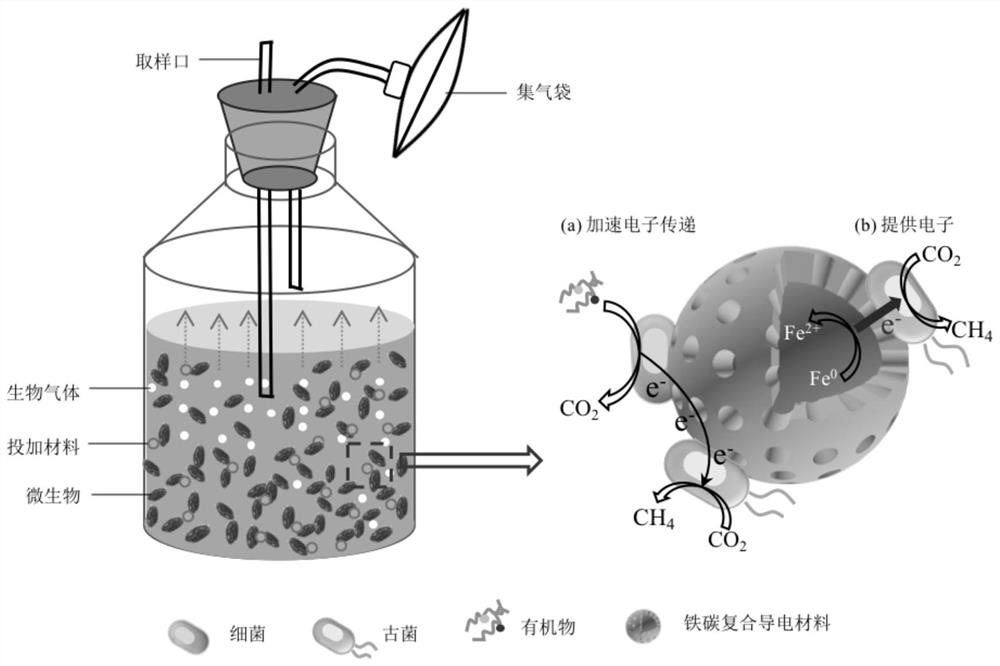

[0035] A method for enhanced anaerobic digestion of methane from sludge based on electron transport was implemented in batch methanogenesis experiments. Using the residual sludge of the secondary settling tank (TS=2.4%~5.3%, VS / TS=44.9%~60.4%) as the substrate, the digested sludge (TS=2.1%~4.8%) in the anaerobic digestion reactor is stably running, VS / TS=33.5%~47.3%) was used as the inoculum, and the methane production experiment of sludge anaerobic digestion was carried out in a serum bottle with a working volume of 1 L.

[0036] Add the iron-carbon composite conductive material 1 with a core-shell structure to the serum bottle, and the mass ratio of the iron-carbon composite conductive material 1 with the core-shell structure to the volatile solids of the residual sludge in the secondary sedimentation tank is 1:2; Add the inoculum sludge and the residual sludge of the secondary settling tank, and the mass ratio of the volatile solids of the inoculating sludge to the volatile...

Embodiment 2

[0048] This example differs from Example 1 in that the mass ratio of the iron-carbon composite conductive material with a core-shell structure to the volatile solids of the residual sludge in the secondary settling tank is 1:1, and the others are the same as in Example 1.

Embodiment 3

[0053] This example differs from Example 1 in that the mass ratio of the iron-carbon composite conductive material 2 with a core-shell structure to the volatile solids of the residual sludge in the secondary settling tank is 2:1, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com