Complex bacterial preparation and application thereof

A technology of composite microbial agent and viable count, which is applied in the field of agricultural microorganisms, can solve the problems of low degradation ability, limited ability to deal with animal excrement, limitations, etc., and achieve the effect of promoting growth, good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 microbial fermented liquid

[0036]This embodiment only takes Escherichia coli (ATCC10795), Trichoderma (ATCC10045), Pseudomonas fluorescens (ATCC11150), and Bacillus subtilis (ATCC10774) as examples to describe the specific content of the invention in detail, and does not limit the composite microorganism of the present invention Selection of four sources of microorganisms in inoculum.

[0037] (1) Activate the above four kinds of microorganisms into slant medium for preservation respectively, and culture them at 25-37°C for 24-48 hours. The slant culture and composition of 4 kinds of microorganisms are as follows:

[0038] Escherichia coli and Pseudomonas fluorescens slant medium adopt LB medium, and the liquid medium is composed of: 10 grams of peptone, 5 grams of yeast extract, 10 grams of sodium chloride, 1000 milliliters of tap water, 15 grams of agar, pH=7.2;

[0039] Trichoderma species slant medium adopts PDA medium, and the me...

Embodiment 2

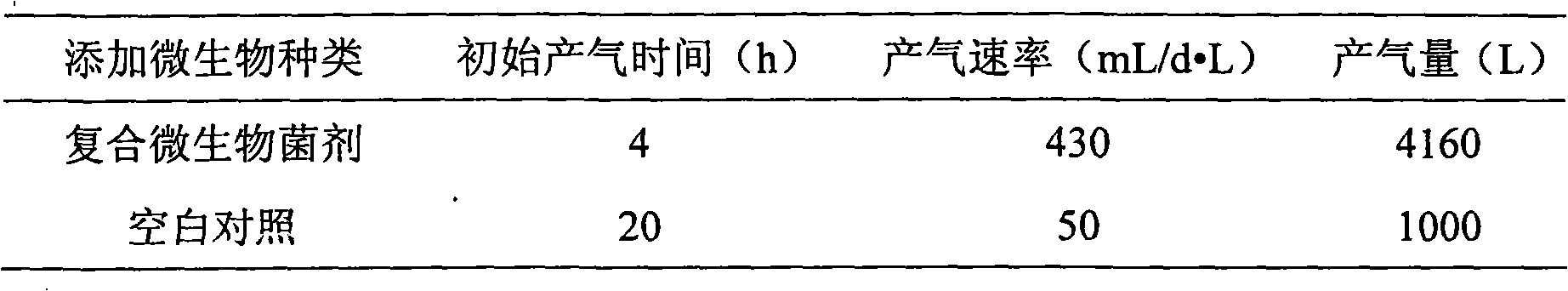

[0050] Embodiment 2: Utilize compound microbial bacterial agent to process cow dung anaerobic fermentation to produce biogas

[0051] (1) Four kinds of microbial fermented liquids prepared in embodiment 1 are mixed uniformly by the following weight parts to become composite microbial inoculum: 1 part of escherichia coli liquid, 2 parts of Trichoderma liquids, 2 parts of Pseudomonas fluorescens liquids, 4 parts of Bacillus subtilis share.

[0052] (2) Get 600 kilograms of fresh cow dung from the dairy farm, add water to prepare a mixture with a water content of about 95%, divide it into two equal parts according to the mass, and add it to two identical fermentation tanks (with a volume of 1000 liters).

[0053] (3) Add a methanogenic inoculum (selected from cesspit sediment) whose dry weight accounts for 10% (g / g) of the mixture of cow dung and water, and adjust the pH to 6.8-7.2.

[0054] (4) In one of the anaerobic fermentation tanks, add the composite bacterial agent prepar...

Embodiment 3

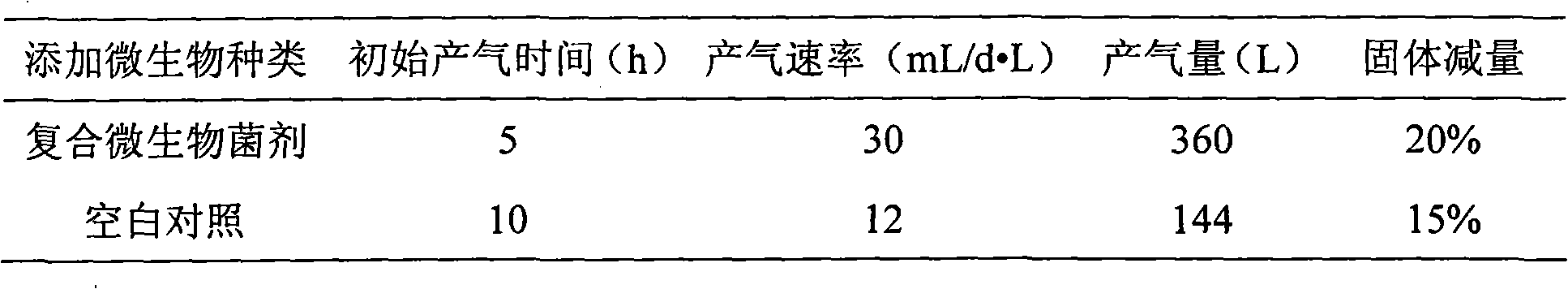

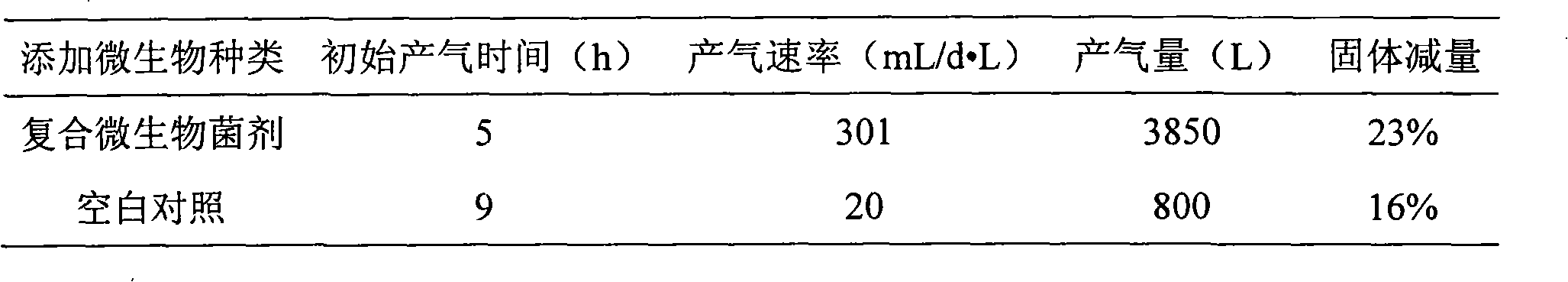

[0057] Example 3: Biogas production by anaerobic fermentation of straw by using compound microbial agent

[0058] (1) Four kinds of microbial fermented liquids prepared by embodiment 1 are mixed uniformly to become composite microbial inoculum by following parts by weight: 2 parts of escherichia coli liquid, 2 parts of Trichoderma liquids, 2 parts of Pseudomonas fluorescens liquids, 5 parts of Bacillus subtilis share.

[0059] (2) Choose 400kg of rice straws that are not polluted by toxic substances, and cut them short manually or mechanically, with a length of less than 3cm.

[0060] (3) Add water equivalent to 2 times the mass of the straw to the crushed straw to moisten it, stir it well overnight to make the straw swell.

[0061] (4) Add quicklime (calcium oxide) with 1% mass of straw raw material to the swollen straw, mix evenly, and stack retting. The stack retting temperature is kept at 50° C. for 6 days.

[0062] (5) Divide the stacked retting straw into two equal par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com