Preparing method and application of nitrogen-doped magnetic biochar

A technology of biochar and nitrogen doping, applied in chemical instruments and methods, waste fuels, carbon compounds, etc., can solve the problems of easy agglomeration of particles, heavy metal pollution, high cost, etc., and achieve simple operation, increased biodegradability, and reduced The effect of preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

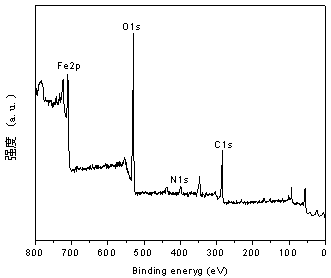

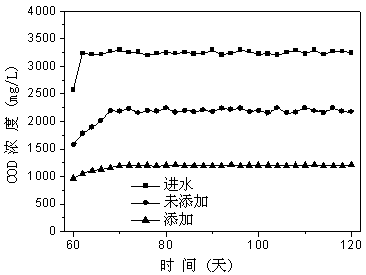

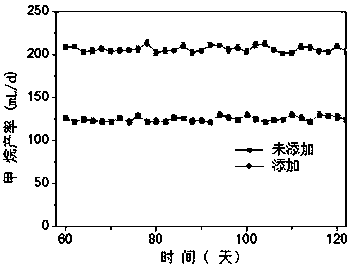

Embodiment 1

[0035] Wash the agricultural and forestry waste soybean protein residues, and crush them to 0.1~1cm slag by using a pulverizer. The waste iron sludge from the Fenton oxidation process is cleaned, dried, and ready for use, wherein the iron content is 30wt% and above. The weight ratio of soybean protein residue to iron sludge is 2:0.5, 3mol / L KOH is used as medium and activator, the volume ratio of solid to liquid is 3:0.1, and 3wt% bentonite is used as a binder to be uniformly dispersed into the liquid through an ultrasonic disperser medium. The hydrothermal carbonization is assisted by microwave, the microwave power is 250W, the hydrothermal carbonization temperature is 180°C, the stirrer is mixed at 90 rpm, and the reaction time is 5 hours. After the hydrothermal reaction, cool to 60°C, pickle with 0.5mol / L HCl, then wash with distilled water until the pH does not change, filter with a vacuum pump to obtain hydrothermal biochar with a moisture content of 30 wt%, and dry at 9...

Embodiment 2

[0043] Clean the water hyacinth which is agricultural and forestry waste, and crush it to 0.1-1cm slag with a crusher. The waste iron sludge from the Fenton oxidation process is cleaned, dried, and ready for use, wherein the iron content is 30wt% and above. The weight ratio of water hyacinth to iron mud is 2:0.3, 3mol / L ZnCl 2 As a medium and an activator, the volume ratio of solid to liquid is 3:0.2, and 4wt% bentonite is uniformly dispersed into the liquid medium as a binder by an ultrasonic disperser. Microwave-assisted hydrothermal carbonization was adopted, the microwave power was 300W, the hydrothermal carbonization condition was 210°C, the stirrer was mixed at 80 rpm, and the reaction time was 4 hours. After the hydrothermal reaction is completed, cool to 60°C and use 0.5mol / L H 3 PO 4 Pickling, then distilled water washing until the pH does not change, vacuum pump filtration to obtain hydrothermal biochar with a moisture content of 20 wt%, drying at 90°C for 12 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com