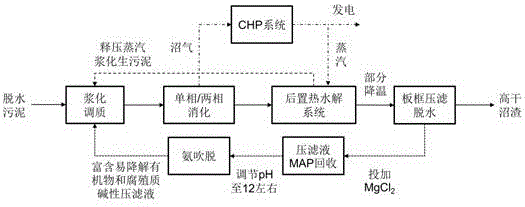

Sludge resource recovery method based on hydrothermal treatment of digested sludge

A technology for hydrothermal treatment and sludge digestion, which is applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. It can solve the problem of digestive system inhibition, energy and volume waste, and insufficient nitrogen and phosphorus resources. Recycling and other problems to achieve the effect of improving the system degradation rate and methane yield, improving dehydration performance, and reducing the amount of dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The solid content of the dewatered sludge in the urban sewage treatment plant is 20%, and the VS / TS is about 55%. The dewatered sludge and the digested sludge are mixed and tempered by the dewatered liquid filtered by the plate and frame. In theory, the thermal hydrolysis reflux pressure The filtrate reflux can dilute the solid content of the feed to about 15%, and the hot water pressurized steam can heat the feed sludge to about 60 °C. Below 10, the pulped sludge is pumped into the medium temperature digestion system for efficient methane production, the digestion temperature is 35±1℃, and the residence time is 15-20d. The solid content of the digested sludge is about 12%, which can be directly treated by thermal hydrolysis. The hydrothermal temperature is 120 °C and the time is 60 minutes. Because the sludge has undergone anaerobic digestion, the easily degradable substances have been degraded, reducing thermal hydrolysis. System volume and energy consumption. After t...

Embodiment 2

[0041] The solid content of the dewatered sludge in the urban sewage treatment plant is 15%, and the VS / TS is about 60%. The slurry sludge enters the high temperature acidification section at 55°C. Since the sludge contains a large amount of reflux dissolved organic matter, the residence time can be shortened to 2d, and the acid can be produced efficiently in a short time. Then it enters the medium temperature methane production reactor at 35°C, and the residence time is 14d. The methane production process is basically completed. Compared with traditional anaerobic digestion, the residence time can be greatly shortened and the reactor volume can be reduced. The digested sludge is treated by thermal hydrolysis, the solid content is about 10%, the hydrothermal temperature is 175 °C, and the hydrothermal time is 30 minutes. After treatment, the sludge viscosity can be reduced to less than 1 / 10 of the original sludge. After the partial cooling of the thermally hydrolyzed sludge, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com