Method for producing methane by combination fermentation of paper mill sludge and food waste

A technology of food waste and papermaking sludge, applied in biochemical equipment and methods, biological sludge treatment, solid-phase fermentation bioreactor, etc., can solve the constraints of anaerobic digestion application, high secondary fiber content, protein content Low-level problems, to achieve the effect of improving bioconversion rate, high methane yield, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) The papermaking sludge used in the test was taken from the sludge dehydration workshop of a paper mill in Guangdong Province, and the retrieved fresh sludge was evenly dispersed;

[0031] (2) The experimental kitchen waste was taken from a student canteen of a university in Guangdong Province. The retrieved fresh kitchen waste was first sorted to remove solids with larger particle sizes (such as corncobs, plastic bags, etc.), and then mixed with water Mix according to a certain ratio, and crush it with a food crusher until the particle size can pass through a 40-mesh sieve;

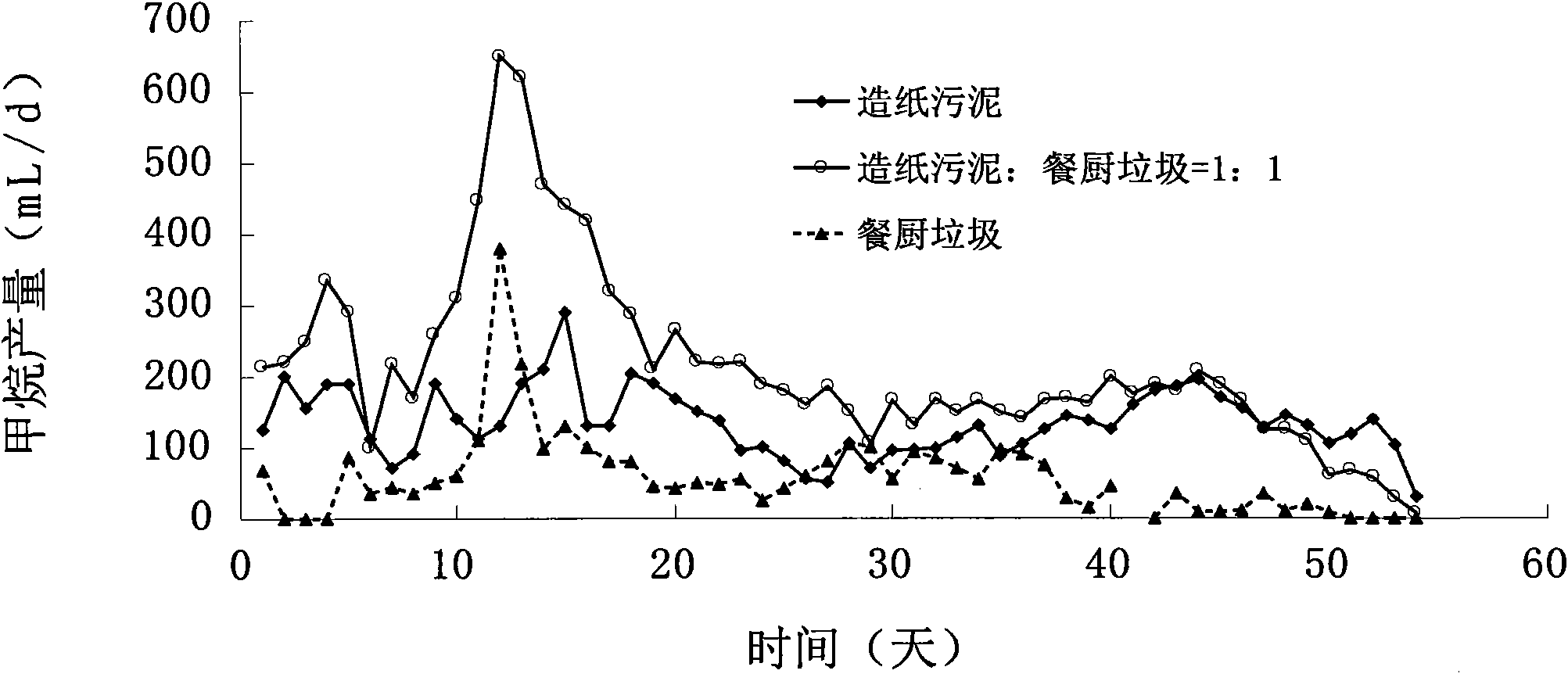

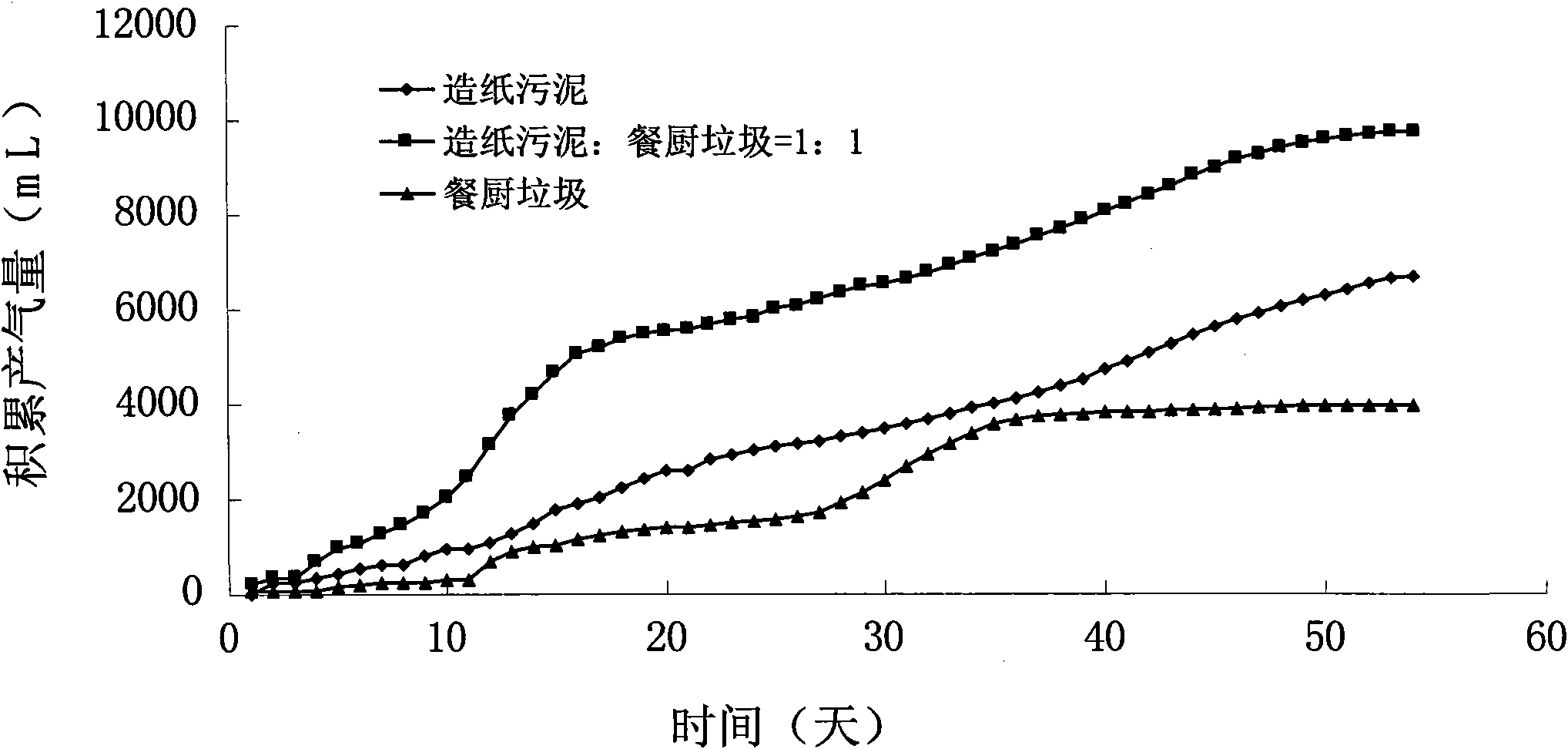

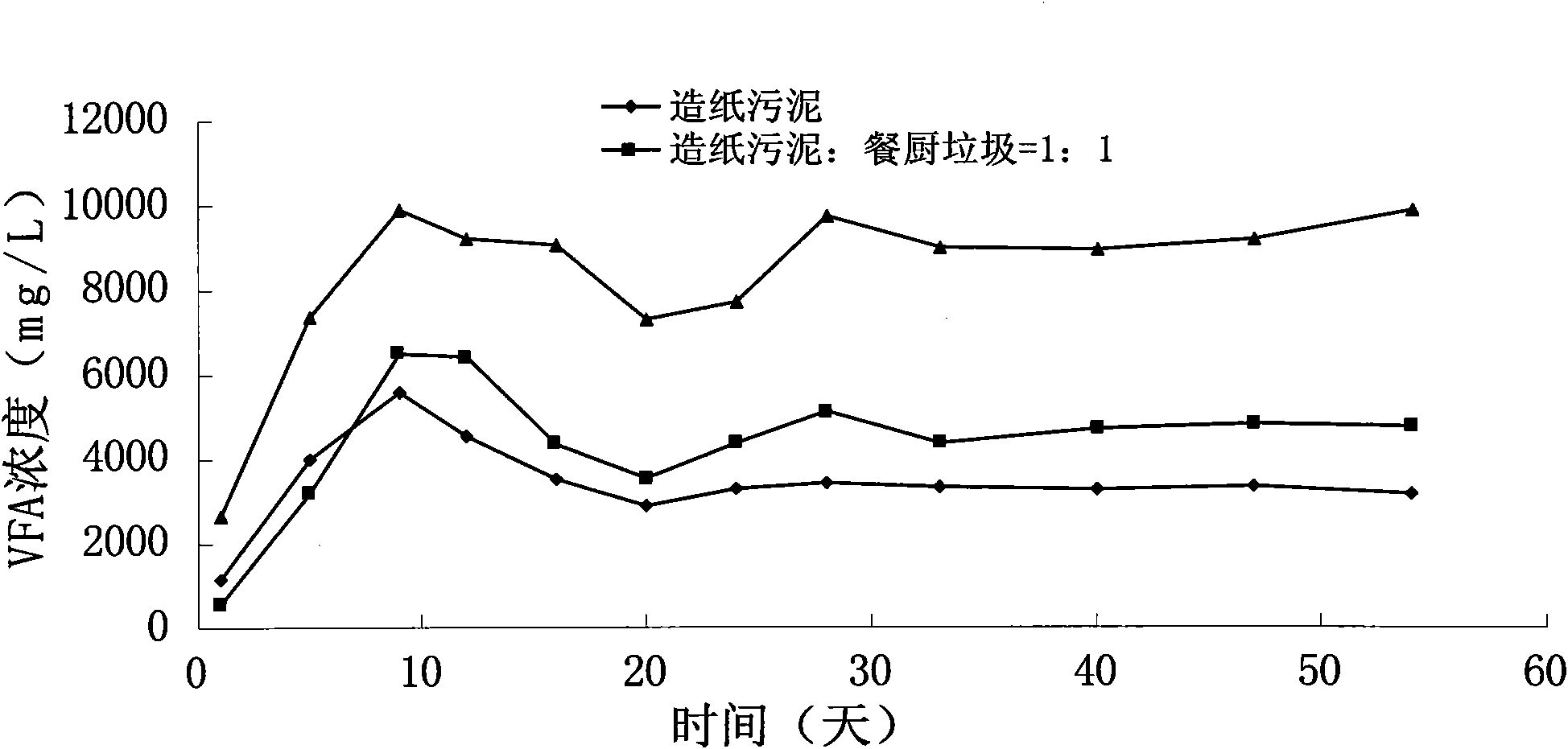

[0032] (3) Evenly mix the papermaking sludge dispersed in step (1) and the pretreated kitchen waste in step (2) according to the volatile matter (VS) mass ratio of 1:1, wherein the amount of papermaking sludge added was 114.6g, and the amount added to the kitchen waste was 94.7g; the total volatile matter content of the mixture was 29.3g;

[0033] (4) The papermaking sludge (the quality of the...

Embodiment 2

[0039] (1) The papermaking sludge used in the test was taken from the sludge dehydration workshop of a paper mill in Guangdong Province, and the retrieved fresh sludge was evenly dispersed;

[0040] (2) The experimental kitchen waste was taken from a student canteen of a university in Guangdong Province. The retrieved fresh kitchen waste was first sorted to remove solids with larger particle sizes, and then crushed with a food crusher until the particle size could reach Pass 40 mesh sieve;

[0041] (3) The papermaking sludge dispersed in step (1) and the pretreated kitchen waste in step (2) are mixed according to the volatile matter (VS) mass ratio of 5:1, 3:1, 1:1, 1: 3, 1:5 for uniform mixing.

[0042] (4) Add the mixture obtained in step (3) into the anaerobic reactor of 1000mL respectively. According to the dry matter quality of the inoculated sludge being 10% of the dry weight of the fermentation raw material, add 70g of anaerobic reactor with a water content of 90.71%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com