Nickel-based methanation catalyst dispersive in SBA-15 ducts and preparation and application thereof

A nickel-based methane and catalyst technology, which is applied in the field of nickel-based methanation catalysts and their preparation and application, can solve the problems of difficulty in dispersing uniform active components on the surface of the metal carrier, migration of active components, cumbersome preparation process, etc., and achieve the goal of preparing The method is simple and easy to implement, cost-effective advantages, and the effect of high metal dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) 0.55g nickel nitrate hexahydrate and 0.55g sodium dodecyl sulfate (SDS) are dissolved in 10g deionized water;

[0037] (2) Weigh 1.0g of SBA-15 white powder, add SBA-15 white powder into the solution and soak for 10h, take out after dipping, dry in vacuum at 50°C for 8h, then bake in air at 500°C for 5h, and cool to room temperature naturally, That is, the Ni / SBA-15 catalyst was prepared, which was recorded as 10% Ni / S15 (S1), and the nickel loading was 10 mol%.

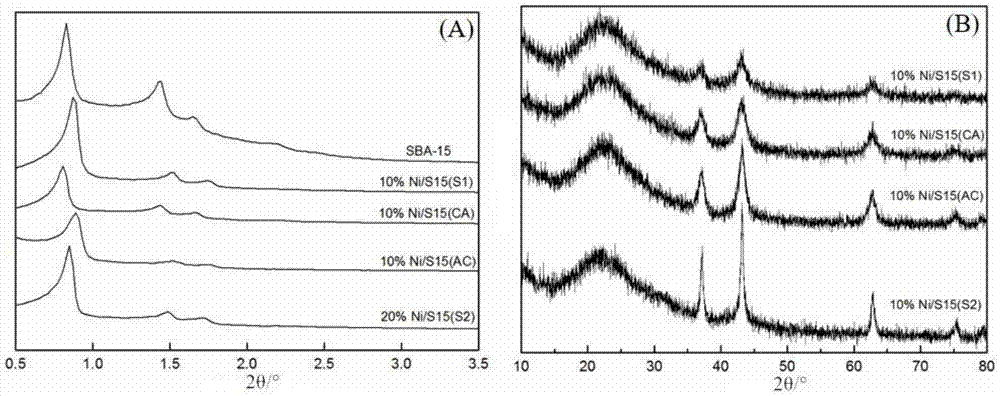

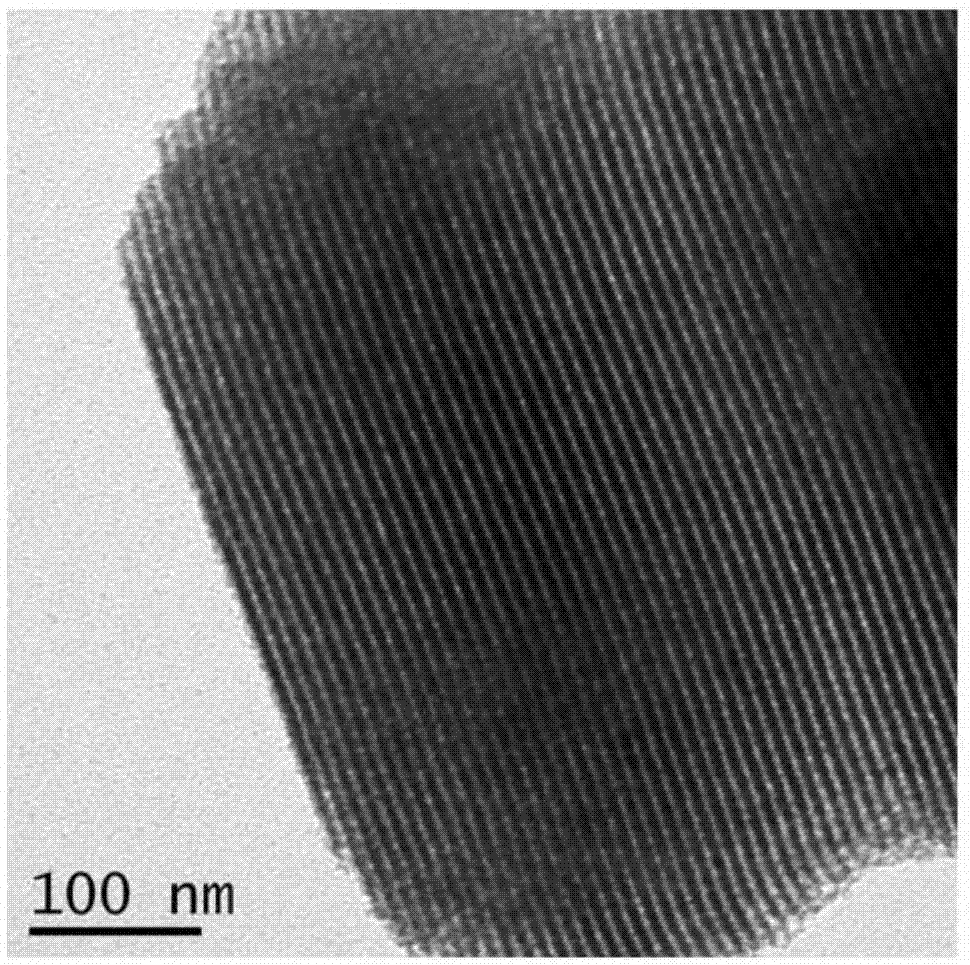

[0038]The 10%Ni / S15(S1) prepared in this embodiment has small angle and wide angle XRD patterns as figure 1 As shown, the TEM picture is as figure 2 (B) shown. Depend on figure 1 (A) It can be seen that the sample has relatively clear (100), (110), and (200) peaks, these peaks are the characteristic peaks of the regular mesoporous molecular sieve SBA-15, indicating that the introduction of metallic nickel did not destroy the original carrier. Some ordered mesoporous structure. Depend on figure 1 (B)...

Embodiment 2

[0040] Substitute sodium lauryl sulfate in embodiment 1 with citric acid, all the other are the same as embodiment 1, make Ni / SBA-15 catalyst, record as 10%Ni / S15(CA), nickel load is 10mol%.

[0041] The catalyst 10%Ni / S15(CA) that present embodiment prepares, its small-angle and wide-angle XRD collection of patterns are as follows figure 1 shown. From figure 1 (A) It can be seen that the order of mesoporous molecular sieves still exists after the introduction of nickel metal; from figure 1 It can be seen in (B) that compared with the catalyst 10% Ni / S15 (S1), the intensity of the characteristic diffraction peak of NiO has increased, which indicates that the particle size of NiO in the catalyst has increased.

Embodiment 3

[0043] Replace the 0.55g nickel nitrate hexahydrate in embodiment 1 with 0.6g nickel acetate tetrahydrate, all the other are with embodiment 1, make Ni / SBA-15 catalyst, be recorded as 10%Ni / S15 (AC), nickel load capacity is 10mol%.

[0044] Depend on figure 1 (A) It can be seen that the sample has relatively clear (100), (110), and (200) peaks, these peaks are the characteristic peaks of the regular mesoporous molecular sieve SBA-15, indicating that the introduction of metallic nickel did not destroy the original carrier. Some ordered mesoporous structure. Depend on figure 1 (B) It can be seen that in addition to the obvious characteristic broad peaks (15-35°) of silicon oxide on the wide-angle XRD spectrum of the sample, there are also characteristic diffraction peaks of NiO particles (2θ=37.5°, 43.7°, 63.7 °) peak.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com