Method for improving methane-producing performance under synergistic action of mixed quasi-synchronous fermentation of multiple raw materials

A technology of simultaneous fermentation and synergy, applied in fermentation, waste fuel, biological sludge treatment, etc., to achieve the effect of strong stability and good buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

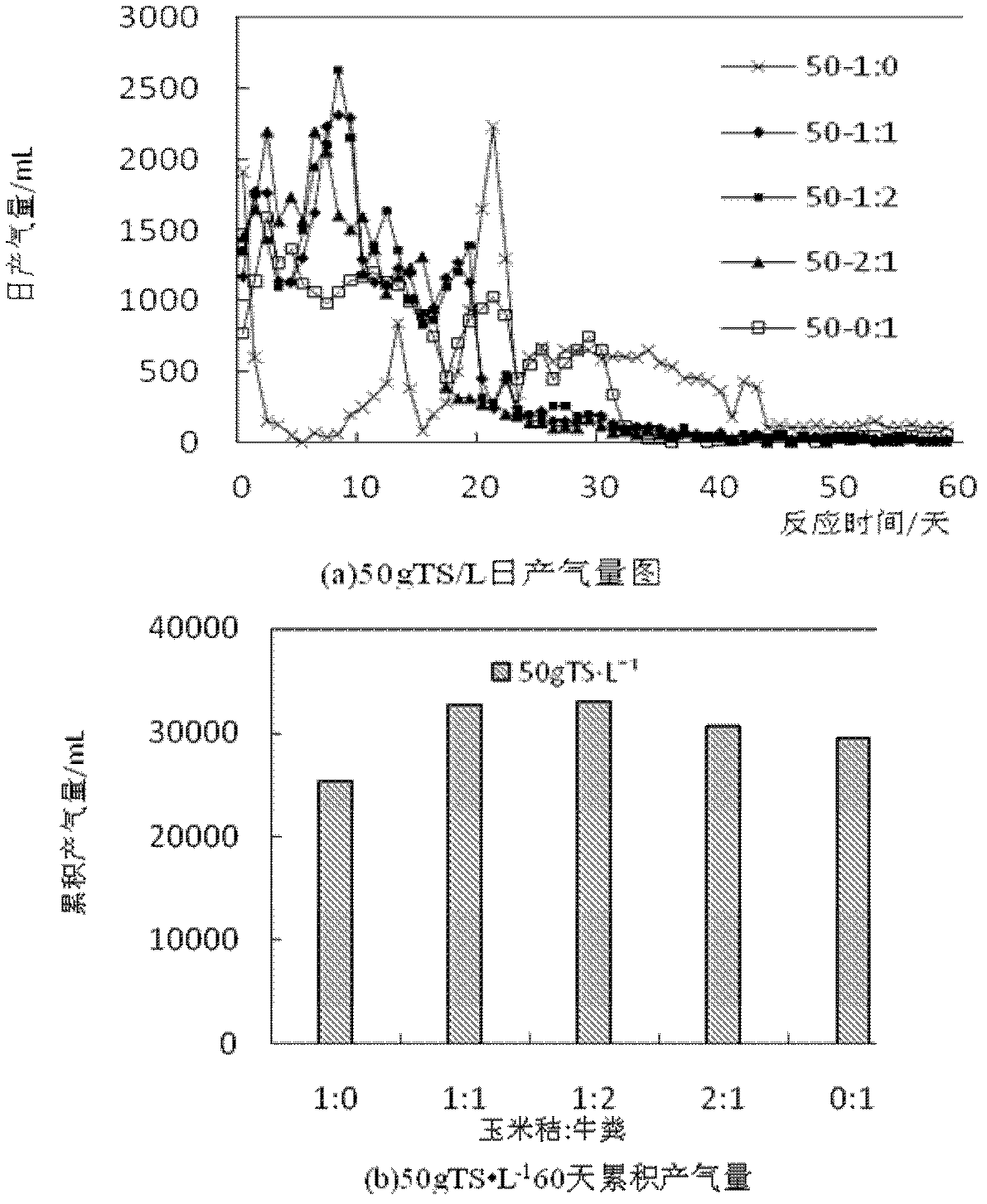

[0041] Gas production performance of mixed anaerobic digestion of pretreated corn stalks and chicken manure in different proportions

[0042] 1) Corn stalks are crushed to 1-5 cm by a straw grinder, mixed with 2% (mass concentration) NaOH solution (the amount of NaOH added is 2% of the dry weight of corn stalks) for pretreatment, and the treatment time is 3 days;

[0043] 2) The crushed and pretreated corn stalks described in step 1 and the chicken manure after removing impurities are used according to the dry matter mass ratio (dry matter refers to the matter after subtracting moisture from fresh raw materials) 1:0, 1:1, 1:2 , 2: 1, 0: 1 ratio (wherein 1: 0 and 0: 1 are respectively pure corn stalks and pure chicken manure) fully mixed;

[0044] 3) Put the mixed substance obtained in step 2 into a 2L conical flask anaerobic digestion reactor, add inoculated sludge (this sludge is taken from Nanwu Biogas Station, Shunyi Suburb, Beijing), fully mix, and inoculate sludge Adding...

Embodiment 2

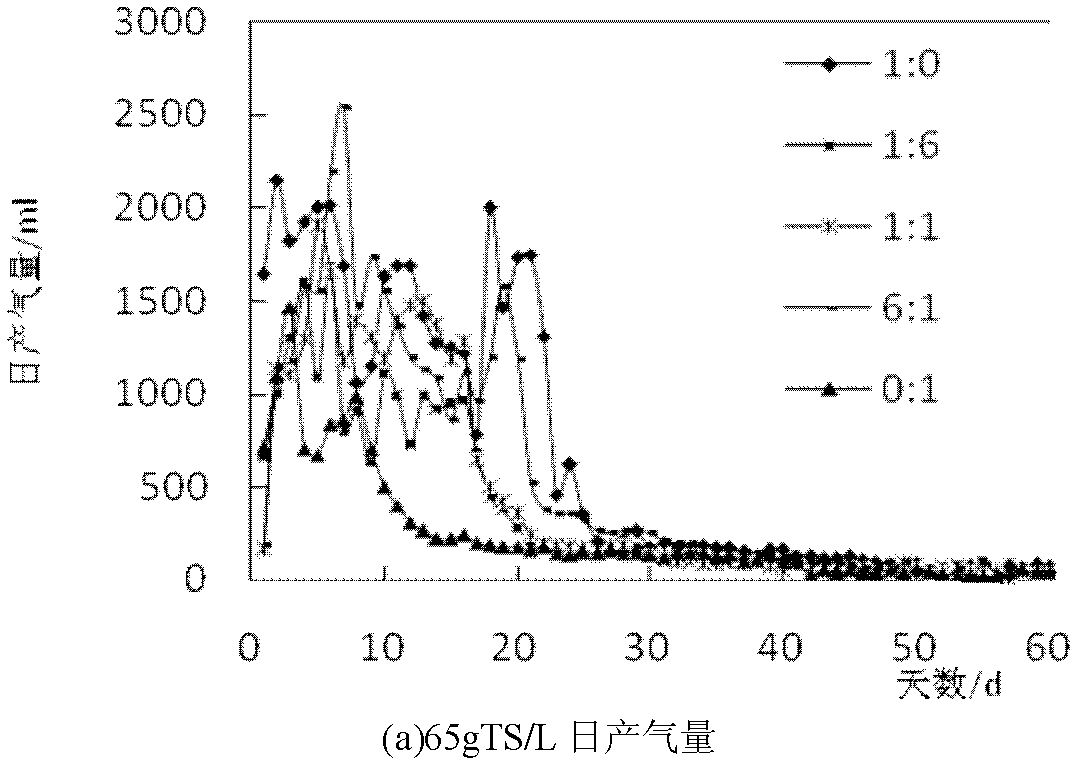

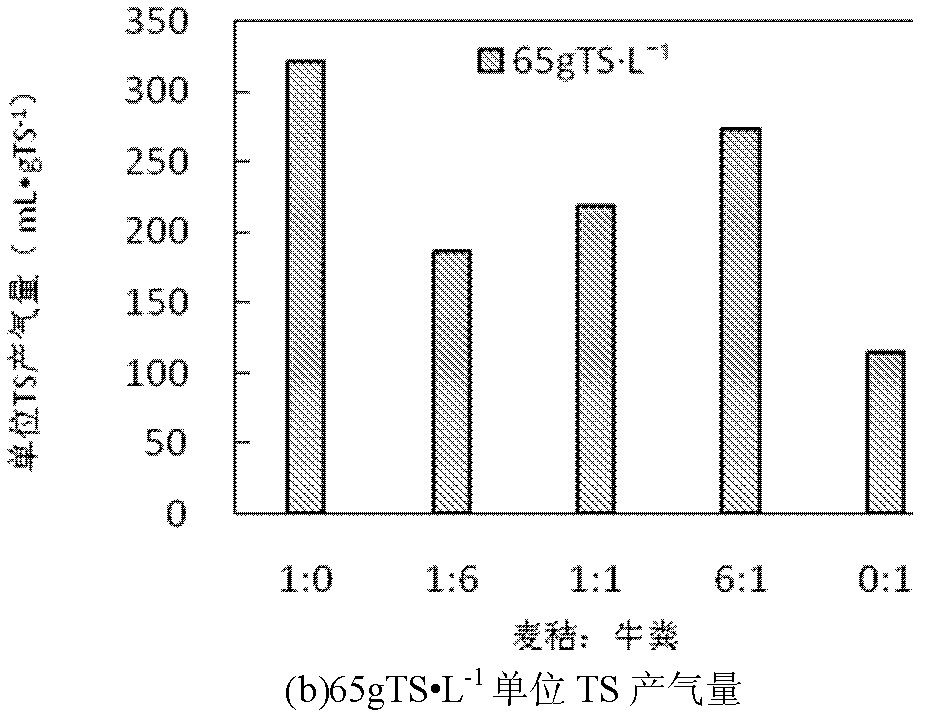

[0052] Gas production performance of mixed anaerobic digestion of pretreated wheat straw and cow dung in different proportions

[0053] 1) The wheat straw is crushed to 1-5 cm by a pulverizer and then mixed with 2% (mass concentration) NaOH solution (the amount of NaOH added is 2% of the dry weight of the straw) for pretreatment, and the treatment time is 3 days;

[0054] 2) the pulverized and pretreated wheat straw and cow dung described in step 1 are in the mass ratio of dry matter (dry matter refers to the material after subtracting moisture from the fresh raw material) 1:0, 1:6, 1:1, 6:1, The ratio of 0:1 (wherein 1:0 and 0:1 are pure wheat straw and pure cow dung respectively) is fully mixed;

[0055] 3) Put the mixed substance obtained in step 2 into a 2L conical flask anaerobic digestion reactor, add inoculated sludge (this sludge is taken from Nanwu Biogas Station, Shunyi Suburb, Beijing), fully mix, and inoculate sludge Adding amount is 10000~20000mg / L (mass in TS), ...

Embodiment 3

[0061] Gas production performance of mixed anaerobic digestion of human manure and pretreated wheat straw in different proportions

[0062] 1) Wheat straw is crushed to 3-5 cm by a pulverizer and then mixed with 2% (mass concentration) NaOH solution (the amount of NaOH added is 2% of the dry weight of the straw) for pretreatment, and the treatment time is 3 days;

[0063] 2) The human feces and the pulverized and pretreated wheat straw described in step 1 are 1:0, 2.75:1, 1.13 according to the mass ratio of volatile dry matter (volatile dry matter refers to the material after subtracting moisture and ash from fresh raw materials) : 1, 0.4: 1, 0: 1 ratio (1: 0 and 0: 1 are pure human manure and pure wheat straw respectively) and mix thoroughly, the C / N ratio after mixing is the optimal ratio for anaerobic digestion ;

[0064]3) Put the mixed substance obtained in step 2 into the 2L conical flask anaerobic digestion reactor, add inoculation sludge (this sludge is taken from Bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com