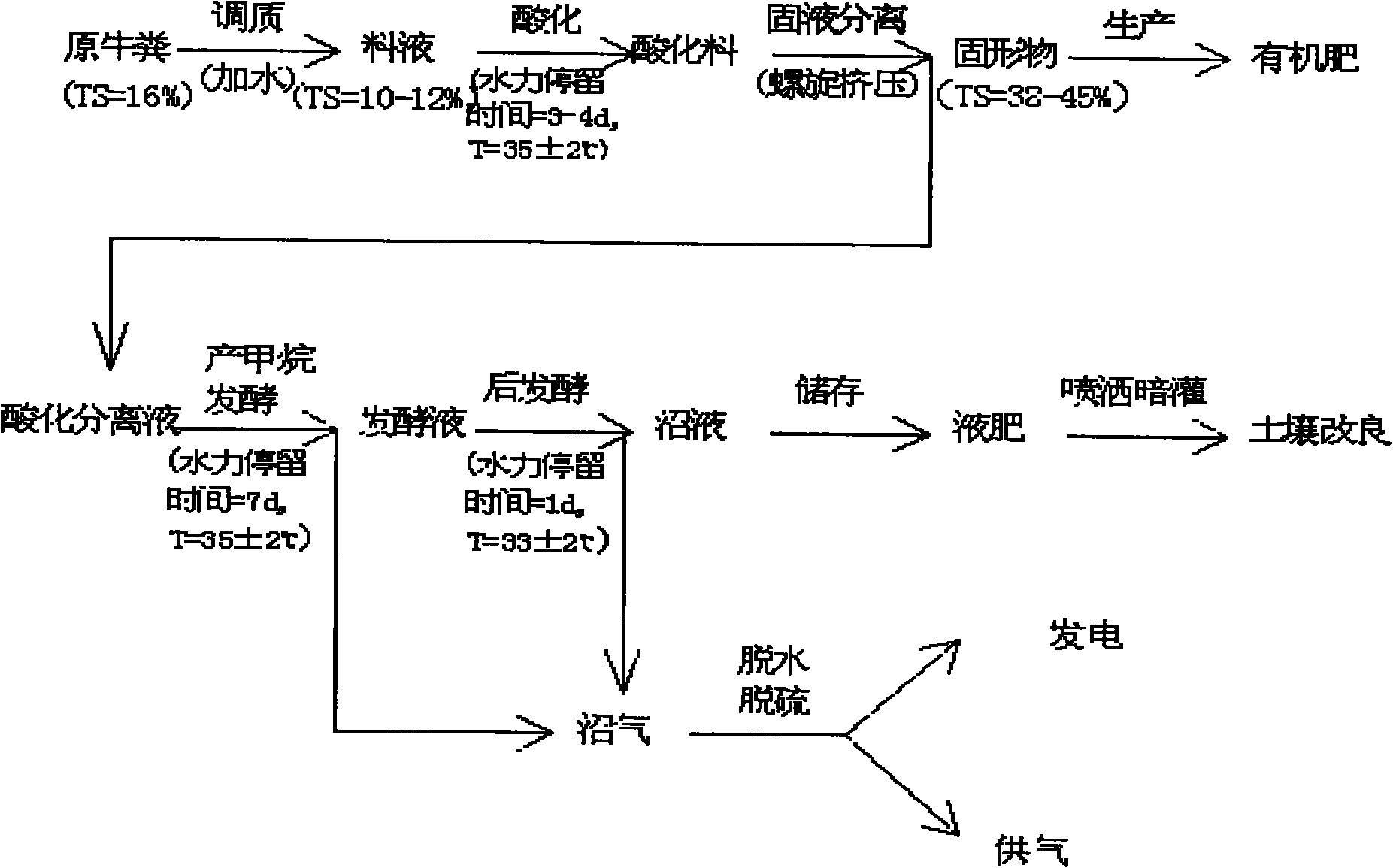

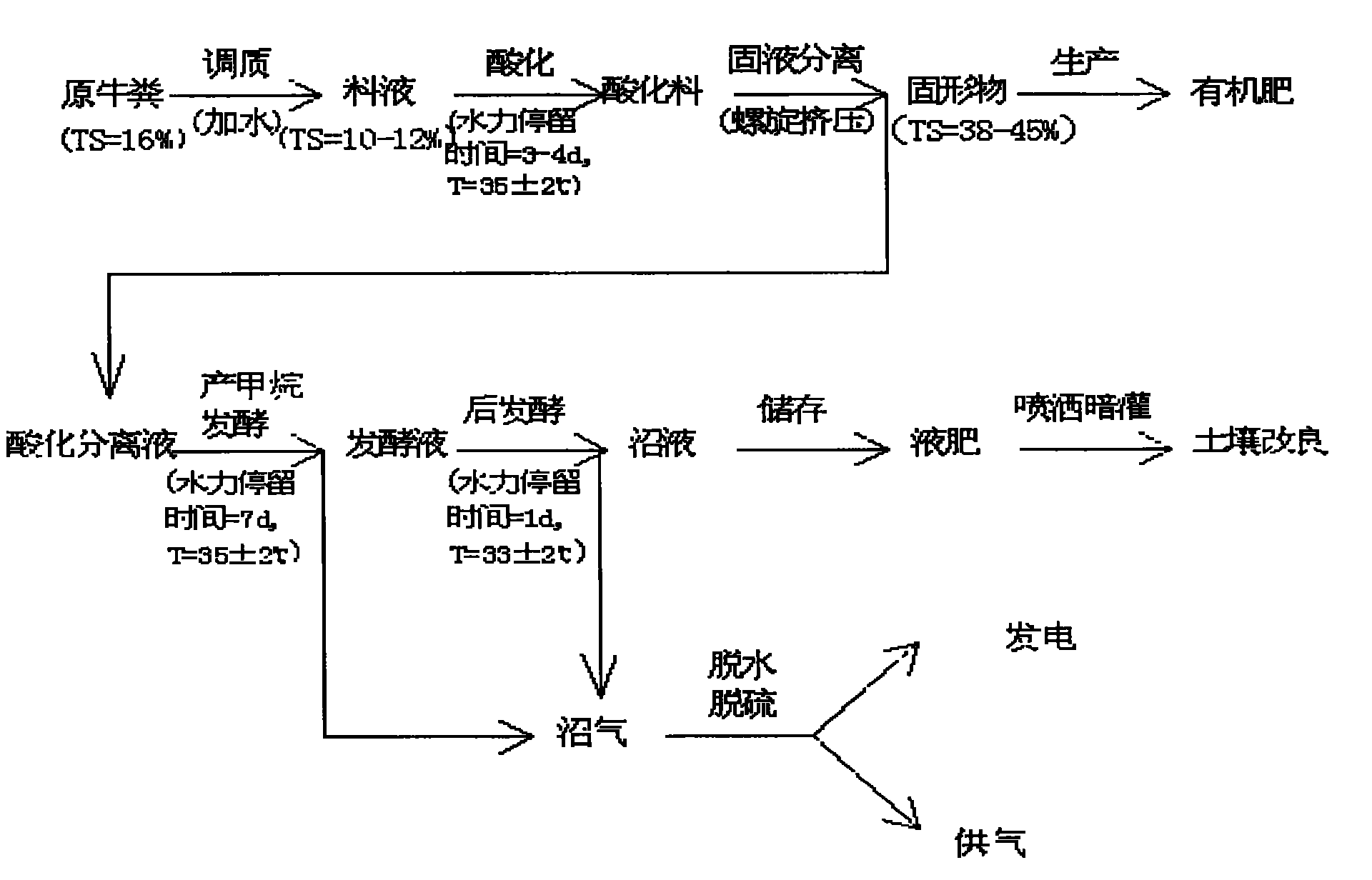

Separation and anaerobic fermentation technology of cow dung subject to acidification

An anaerobic fermentation and cow dung technology, applied in biological sludge treatment, waste fuel, etc., can solve the problems of affecting the economic effect of methane, affecting the gas production efficiency of cow dung fermentation, and low equipment utilization, so as to shorten the hydraulic retention time , Improve equipment utilization and increase methane production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A screw press solid-liquid separator is used to separate the fiber in the cow dung and the fermented liquid raw material after medium-temperature acidification. The acidification process parameters are: cow dung: water is 2:1 for conditioning, and the prepared TS is 10%. Under the condition of medium temperature at 33°C, acidify for 3 days, and the acidified feed liquid is separated by a solid-liquid separator. The total solid content of the separated solids is TS 38%, and the organic compound fertilizer and bio-organic fertilizer are directly produced. The separated liquid TS 6.6%, the viscosity is significantly reduced, and the separated liquid is used for methanogenic anaerobic fermentation. The fermentation temperature is 33°C. The inoculation amount is 30% when the methanogenic phase is started, and the daily feed amount is 1 / 7 of the effective volume of the methanogenic reactor. , the hydraulic retention time is 7 days, and the feed liquid discharged from the metha...

Embodiment 2

[0013] A screw press solid-liquid separator is used to separate the fiber in the cow dung and the fermented liquid raw material after medium-temperature acidification. The acidification process parameters are: cow dung: water is 2:1 for conditioning, and the adjusted TS is 12%. Under the condition of medium temperature at 37°C, acidify for 4 days, and the acidified feed liquid is separated by a solid-liquid separator. The total solid content of the separated solids is TS 45%, and the organic compound fertilizer and bio-organic fertilizer are directly produced. The separated liquid TS 7.4%, the viscosity is significantly reduced, and the separated liquid is used for methanogenic anaerobic fermentation. The fermentation temperature is 37°C. The inoculation amount is 30% when the methanogenic phase is started, and the daily feed amount is 1 / 7 of the effective volume of the methanogenic reactor. , the hydraulic retention time is 7 days, and the feed liquid discharged from the metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com