Method for treating high-concentration water-based ink waste liquid and dehydrating sludge in high-concentration water-based ink waste liquid

A water-based ink, sludge dewatering technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., to achieve continuous production treatment, high dehydration efficiency, and dehydration speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

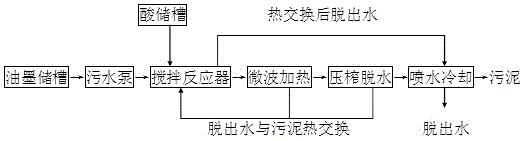

[0026] Embodiment 1 refers to figure 1 .

[0027] The invention provides a method for the treatment of high-concentration water-based ink waste liquid and its sludge dehydration, and uses the method of acidifying the water-based ink waste liquid with inorganic acid to make the pollutants in the waste liquid change from hydrophilic to hydrophobic and form flocs . After microwave heating, the pollutants are aggregated, softened and shrunk, pressed, solidified and dehydrated to form a lumpy sludge. The invention realizes the integration of water-based ink waste liquid treatment and sludge dehydration, has fast dehydration speed and high dehydration efficiency, can reduce the moisture content of sludge to below 40%, and can be continuously produced and treated. For details, refer to the attached figure 1 To illustrate.

[0028] Collect the water-based ink waste liquid and pump it into the stirring reactor, then add inorganic acid to the waste liquid and stir the reaction, adju...

Embodiment 2

[0037] Collect the water-based ink waste liquid and pump it into the stirring reactor, then add inorganic acid to the waste liquid and stir to adjust the pH value of the waste liquid to be acidic, so that the pollutants are precipitated, and the sludge is made into a paste by continuous stirring; After entering the dehydration filter belt, it is heated by microwave and then squeezed for dehydration. The sludge is sprayed with water to cool the surface quickly; the sludge is released from the water and discharged for subsequent treatment. The dewatered sludge on the filter belt is removed and dried naturally.

[0038] The invention provides a method for treating high-concentration water-based ink waste liquid and its sludge dehydration, which mainly includes the following steps:

[0039] Step a. Mix black water-based ink waste (COD Cr : 432,000 mg / L; Chromaticity: 80,000 times) Collected in the ink storage tank, use a sewage pump to add to the stirring reactor, then add inorgan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com