Self-cleaning dust filter

A dust filter and self-cleaning technology, which is applied in the field of dust removal equipment and ventilation, can solve the problems of return air filtration not working normally, slurry becoming dry and hard, dust and other problems, and achieves good sealing, perfect structure and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

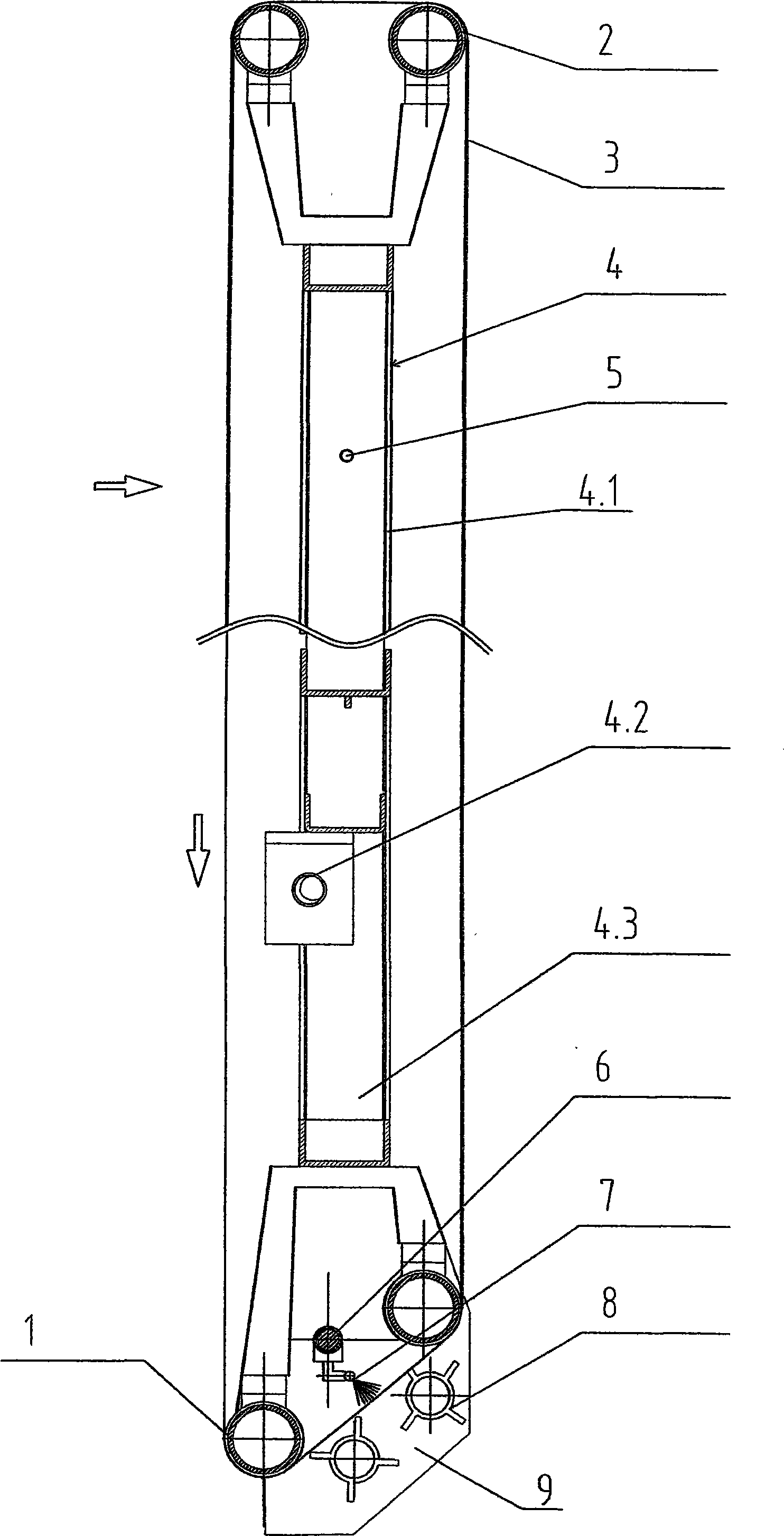

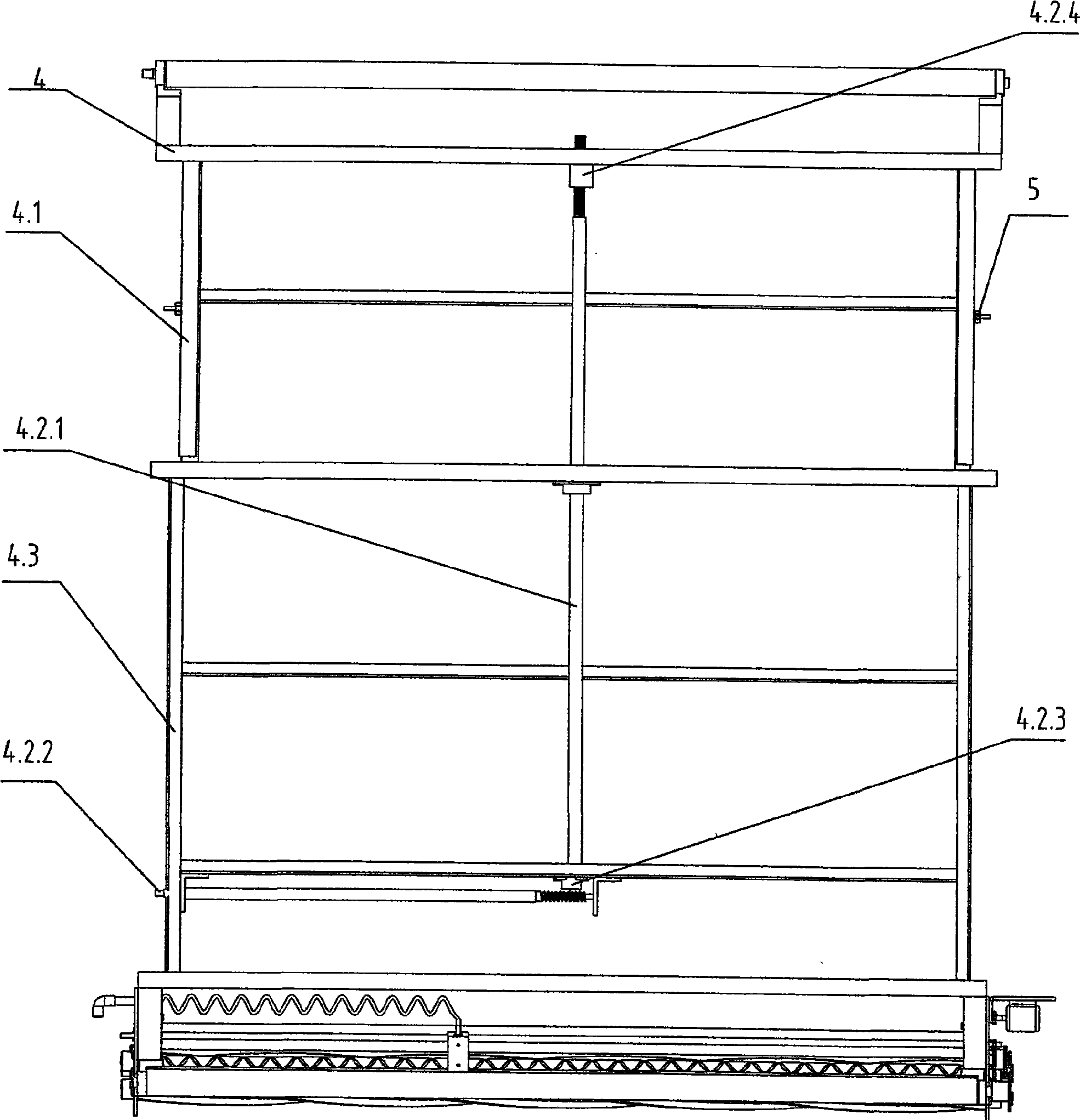

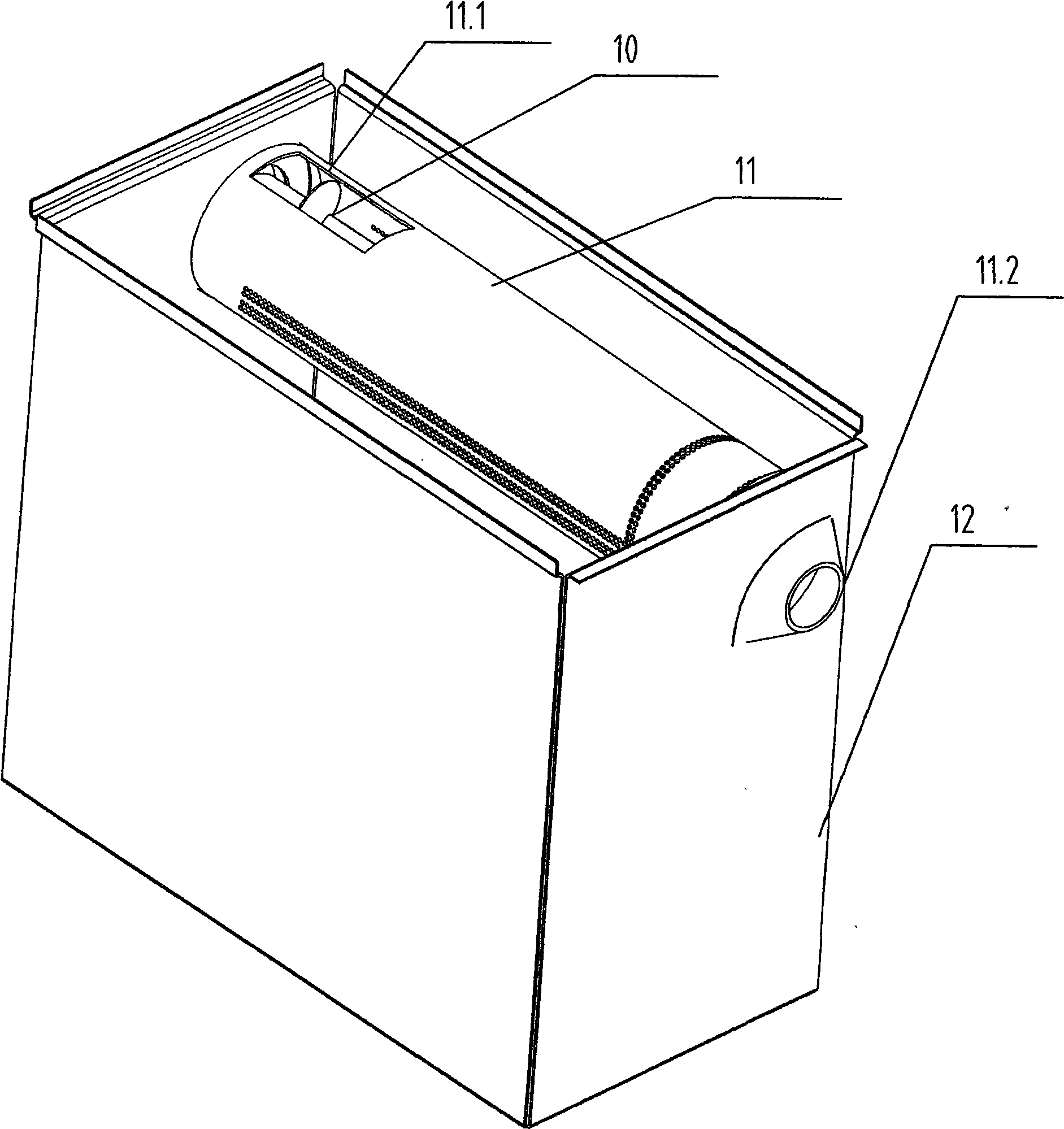

[0016] The self-cleaning dust filter that the present invention relates to mainly consists of a dust filter main body ( figure 1 , 2 ) and water stain separation device ( image 3 ) consists of two parts.

[0017] see Figure 1~2 , the main body of the dust filter is mainly composed of a main body frame 4, a water tank 9, a driving rubber roller 1, a driven rubber roller 2, a conveying filter belt 3, a reciprocating screw 6, a high-pressure water gun 7, a brush roller 8, a transmission motor and a chain, etc. composition. The water tank 9 is arranged at the bottom of the main frame 4, and there are two active rubber rollers 1 installed on the bottom of the main frame 4, and two driven rubber rollers 2 are also arranged on the top of the main frame 4 to convey the filter belt 3 Put it on the driving rubber roller 1 and the driven rubber roller 2 on the main body frame 4, and the conveying filter belt between the two driving rubber rollers 1 is immersed in the water tank 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com