Mining method of open-pit mine

A mining method and open-pit mining technology, which is applied in ground mining, earth drilling, underground mining, etc., can solve the problems of low mine economic benefits, large stripping during the infrastructure construction period, and slow working slope angle, etc., and achieve good economic benefits , balance the production stripping ratio, and reduce the effect of flat plate width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

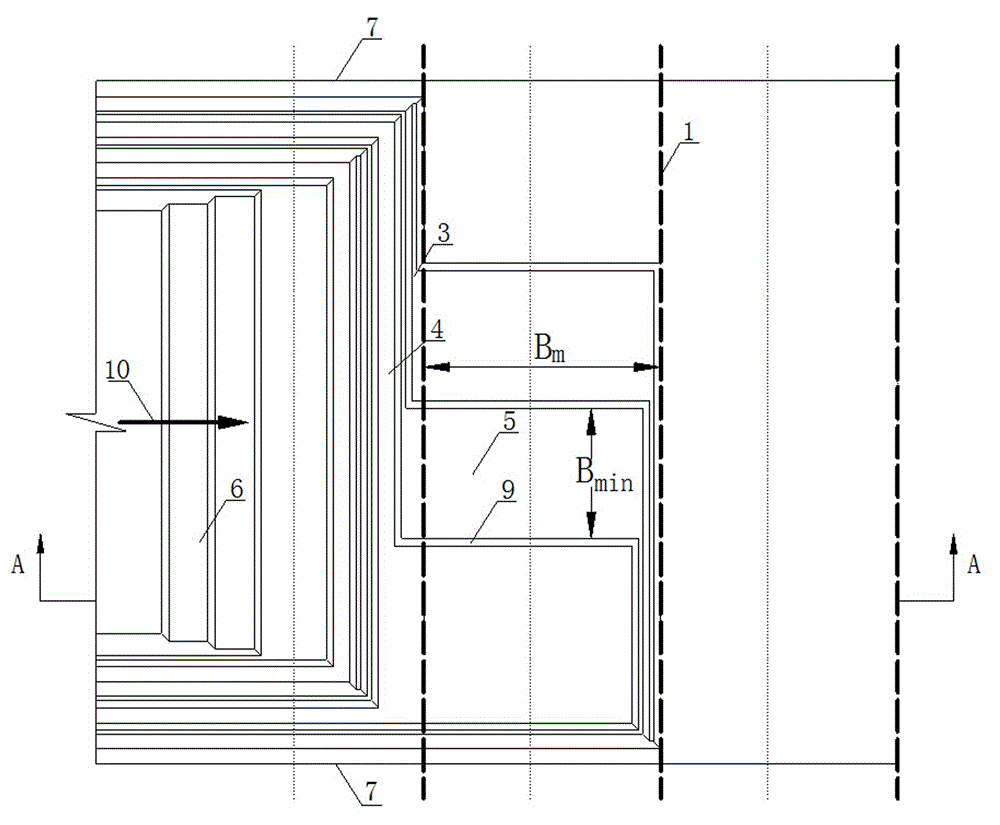

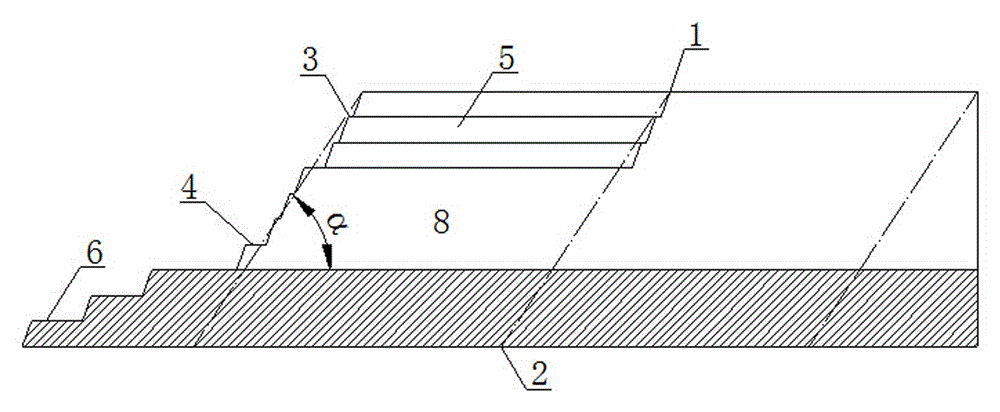

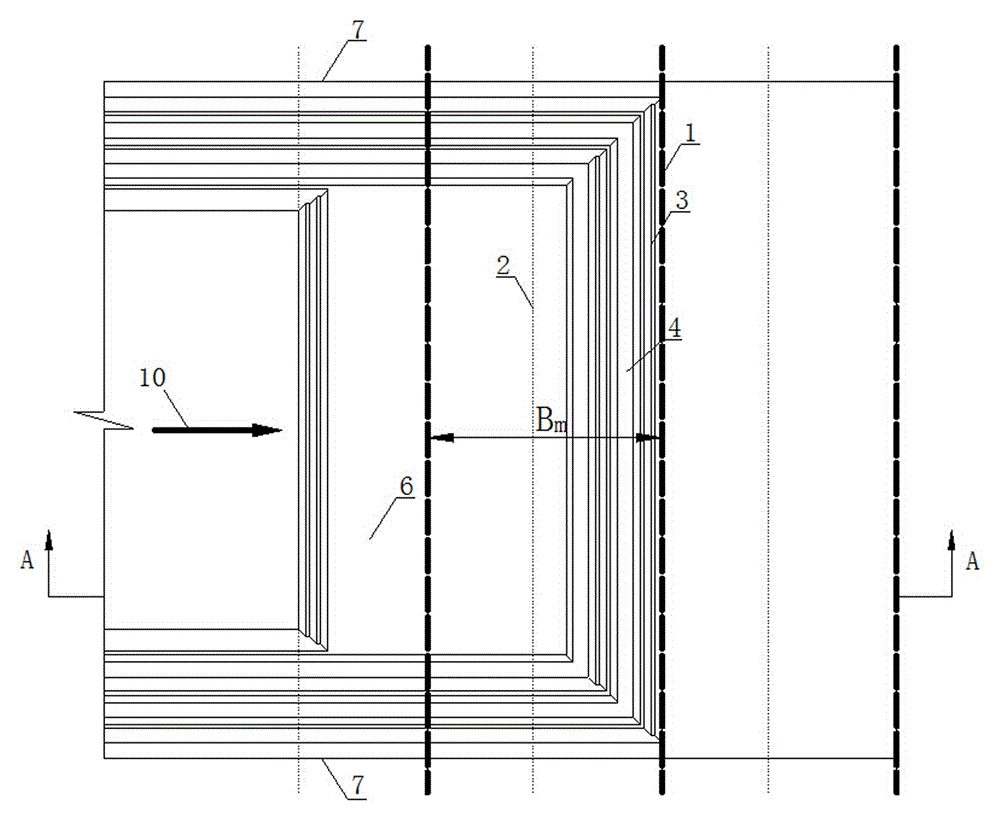

[0017] Such as Figure 1~4 As shown, the open-pit mining method of the present invention divides the stope into several mining strips 8 along the advancing direction of the stope working side. According to the constituent elements of the stope end side slope platform, when strip mining is carried out, the electric shovel working line 9 is arranged horizontally, and 10 sets of safety platforms 3 and cleaning platforms 4 are perpendicular to the working side advancement direction, and the width corresponds to the stope end side slope The components are the same. The working plate is the upper surface of the stripping step 5 and the mining step 6 .

[0018] Stripping the working face of the electric shovel in the strip is horizontally arranged, and is pushed from one end side 7 to the other side end side, and the electric shovel is in a zigzag shape, and the horizontal mining length is the strip width B m , the stripping steps 5 are exposed horizontally. After the stripping wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com