Triangular belt type filter press

A technology of filter press and wedge-shaped belt, which is applied in the direction of press, filter separation, and mobile filter element filter, etc., which can solve the problems of wearing filter belt, large power consumption, and affecting the effective service life of filter belt, so as to increase the shear Function, prolong service life, good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

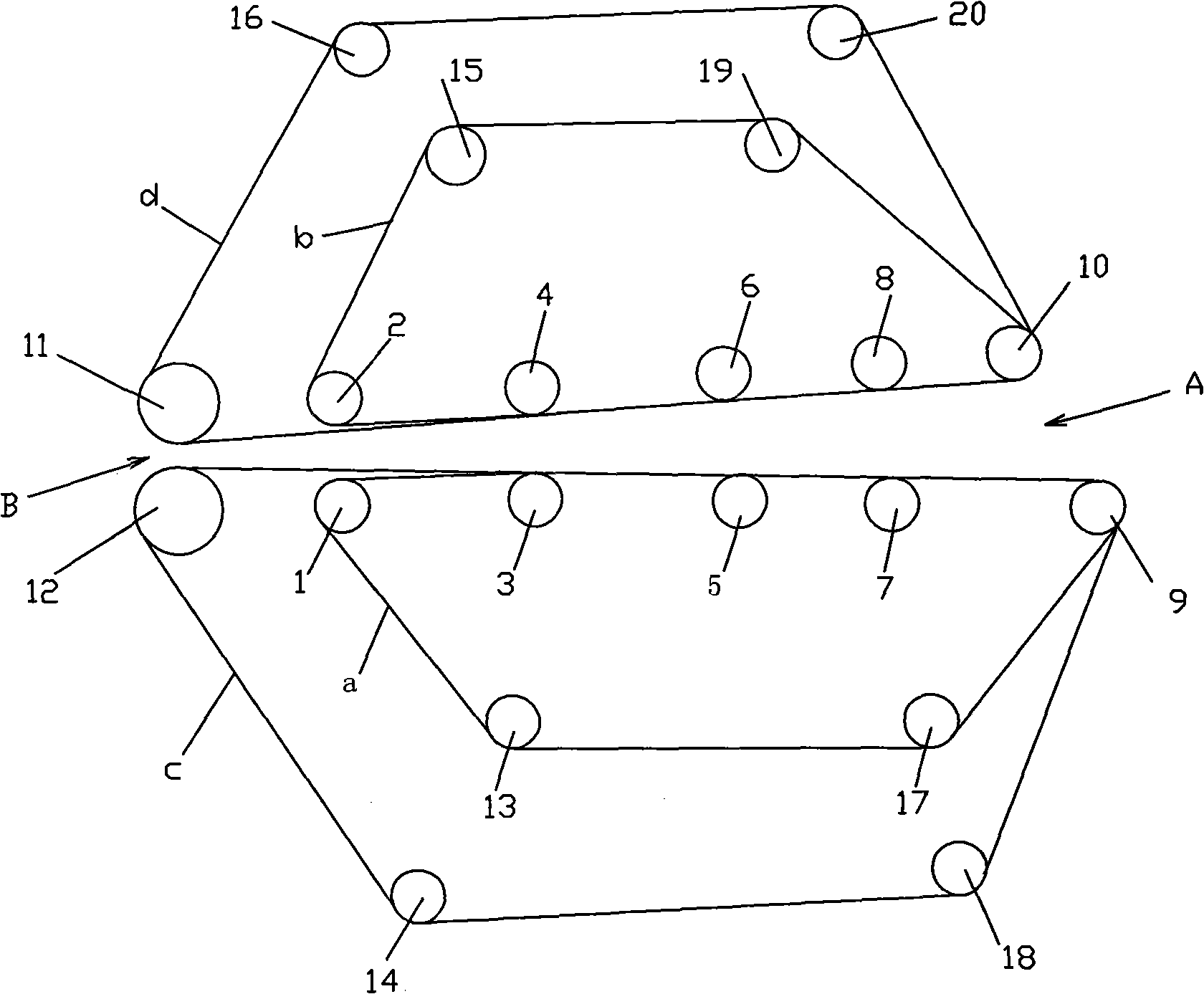

[0014] see figure 1 , Embodiment 1 Wedge belt filter press is mainly composed of frame, pressing area, driving device, feeding device and auxiliary device. The squeeze zone is a wedge-shaped single-press squeeze zone with an angle greater than 0° and less than or equal to 15° between the upper filter belt d and the lower filter belt c. The inlet A of the squeeze zone is larger than the outlet B, and the driving device includes a motor. And gearbox; auxiliary devices include scraper device, water receiving device, deviation correction device and filter belt cleaning device, etc. The pressing area is installed on the frame, the driving device drives the transmission roller in the pressing area, the feeding device faces the feeding port A of the pressing area, the scraper device is installed at the outlet B, and the deviation correction device is installed beside the filter belt in the pressing area , the cleaning device is installed facing the filter belt in the press area, and...

Embodiment 2

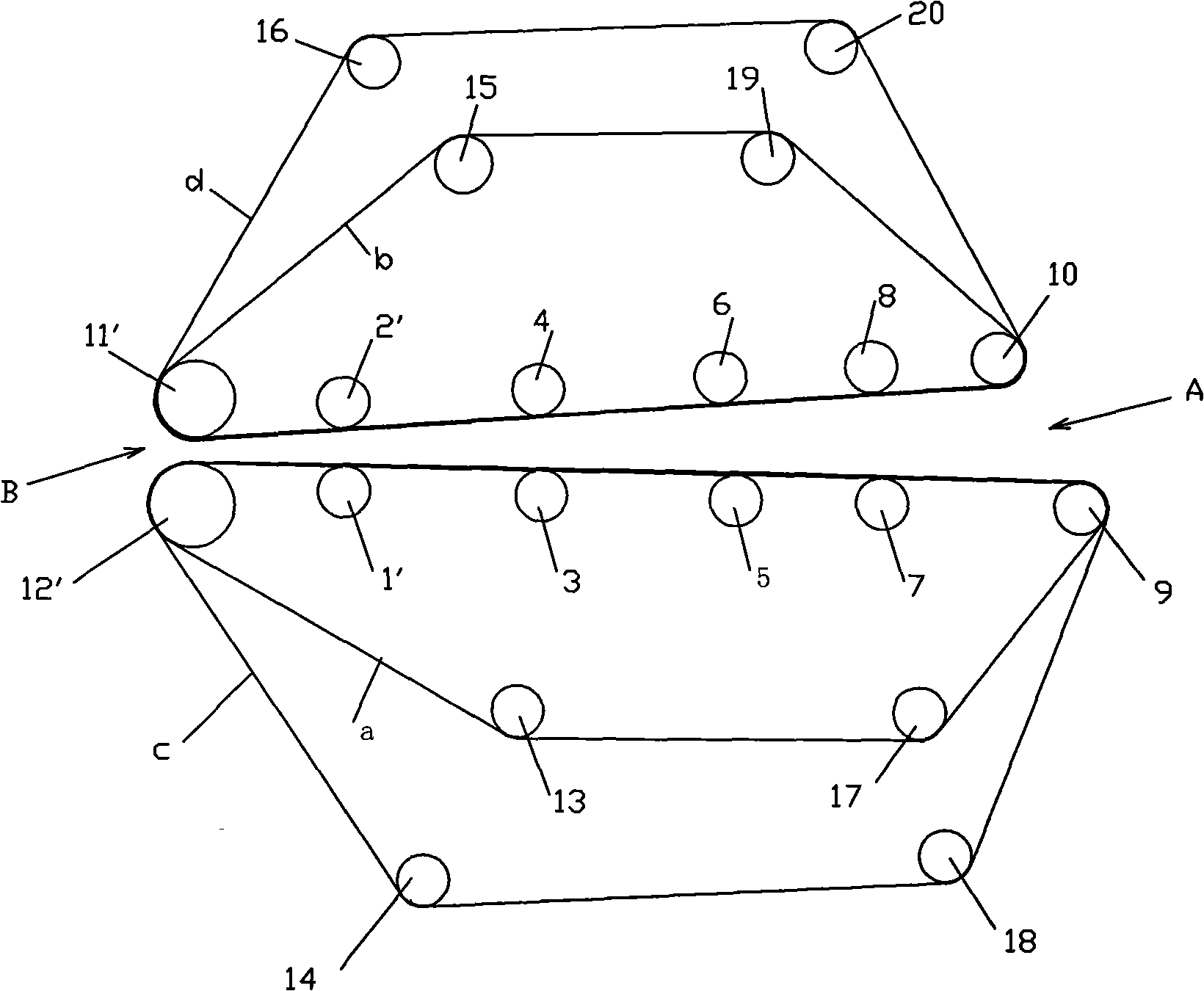

[0022] see figure 2 , this embodiment is different from the transmission device of Embodiment 1. The upper and lower nips each use a transmission part, the tension belt and the filter belt of the upper and lower nips are respectively driven by the same transmission roller, and the upper pressure belt of the upper nip b and the upper filter belt d are wrapped around the upper drive roller 11' at the same time; the lower pressure belt a and the lower filter belt c in the lower press area are wrapped around the lower drive roller 12' at the same time. When the belt filter press is running, The upper tension belt b and the upper filter belt d are driven by the upper transmission roller 11', and the lower tension belt a and the lower filter belt c are driven by the lower transmission roller 12'. 1' in the figure is 9 # Squeeze roll, 2' is 10 # Press rolls, 9 # Press rolls 1' and 10 # Squeeze rolls 2' are arranged in a counterpressing manner.

[0023] Other structures of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com